Yan Mao, Xinglin Tong, Shigang Lu, Weida Chu. Implantable Fiber Bragg Grating Temperature Sensor Inside Lithium-Ion Battery[J]. Laser & Optoelectronics Progress, 2023, 60(17): 1706005

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 60, Issue 17, 1706005 (2023)

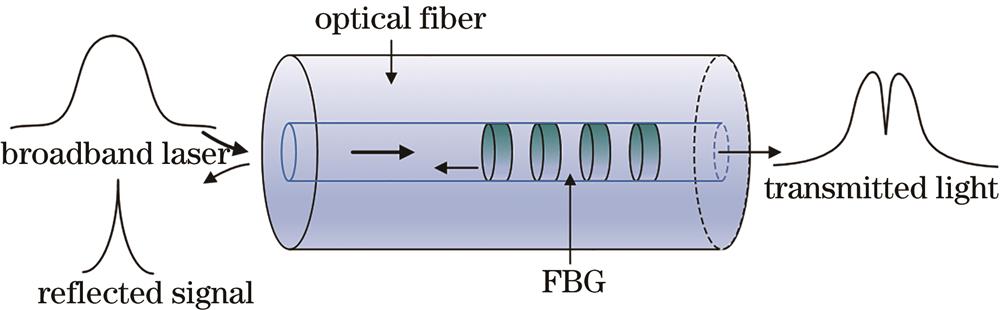

Fig. 1. Sensing principle of FBG

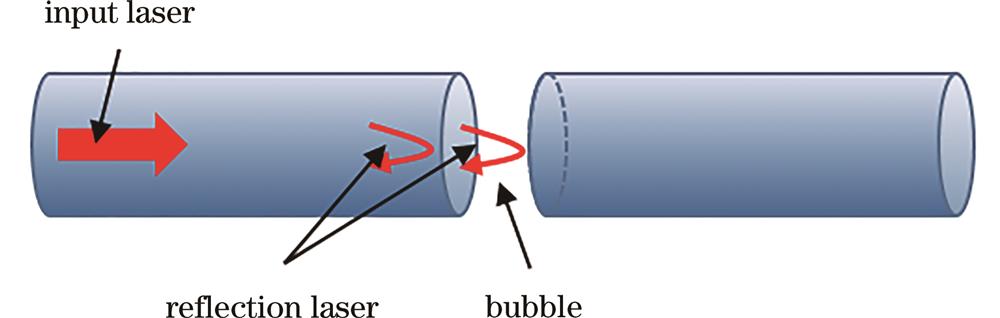

Fig. 2. Structure diagram of optical fiber F-P air chamber

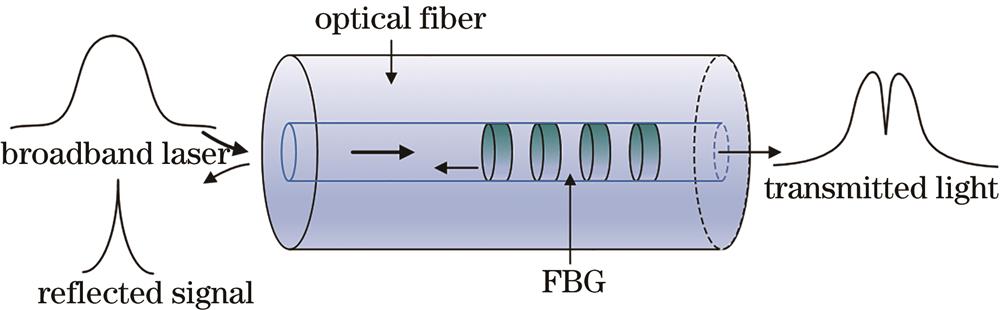

Fig. 3. Reflection spectrum of FBG composite sensor

Fig. 4. Connection relationship of on-line fusion F-P air chamber

Fig. 5. Magnified fine images of tiny F-P air chamber. (a) Image saved by optical fiber fusion splicer; (b) CCD microscope image

Fig. 6. Comparison of F-P interference spectra before and after re-discharge

Fig. 7. Test data fitting for stress relieving

Fig. 8. Schematic diagram of sensor implantation into single lithium-ion battery. (a) Implantation position of sensor; (b) three-dimensional view of sensor after implantation

Fig. 9. Test block diagram of implantable sensor experimental system

Fig. 10. Temperature and voltage variation curves under different charging currents. (a) Test curve with charging current of 1 A; (b) test curve with charging current of 2 A

Fig. 11. Temperature and voltage variation curves under different discharge rates. (a) Test curve with discharge rate of 1 C; (b) test curve with discharge rate of 2 C

|

Table 1. Spectral experimental data

Set citation alerts for the article

Please enter your email address