Baoyan DING, Qiang ZHAO, Dongying CHEN, Dawei DU. Technology and Application Progress of Fiber Bragg Grating Pressure Sensing[J]. Study On Optical Communications, 2024, 50(3): 23001801

Search by keywords or author

- Study On Optical Communications

- Vol. 50, Issue 3, 23001801 (2024)

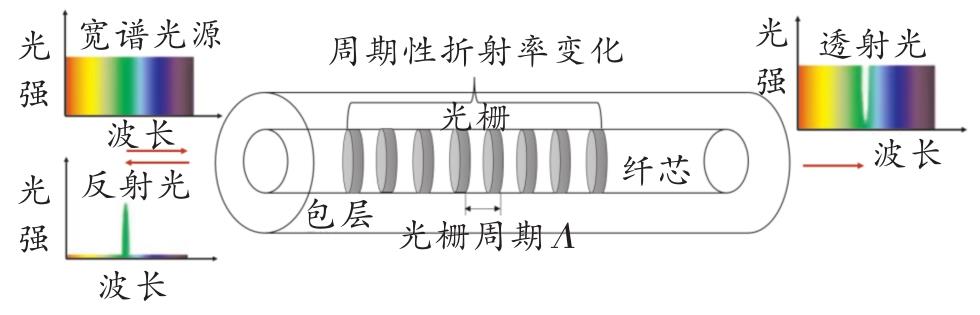

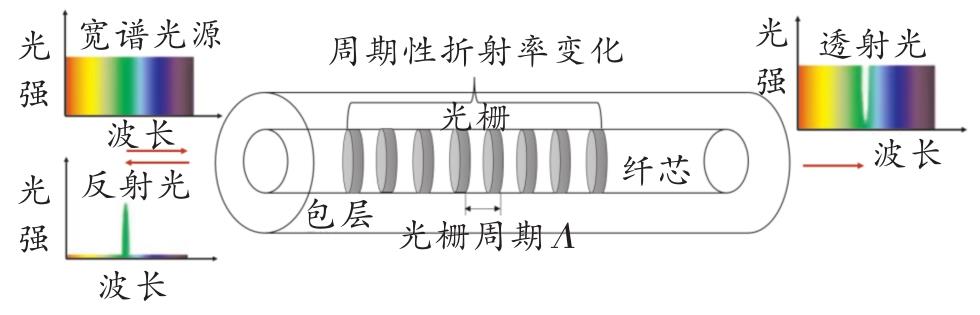

Fig. 1. Structure diagram of FBG

Fig. 2. Diagram of femtosecond laser engraving FBG device

Fig. 3. Structural diagram of pressure sensor with elastic membrane enhanced sensitivity packaging

Fig. 4. Structure and spectrogram of polymer sensitized encapsulated FBG

Fig. 5. Structural diagram of FBG for thin⁃walled cylindrical sensitization packaging

Fig. 6. Structural diagram of corrugated tube encapsulated FBG pressure sensor

Fig. 7. Schematic diagram of FBG structure with cantilever beam and elastic membrane combined sensitization packaging

Fig. 8. Schematic diagram of FBG parallel/series temperature compensation

Fig. 9. Schematic diagram of double-sided adhesive FBG for elastic components

Fig. 10. Structural diagram and reflection spectrum of a single grating semi bonded semi free FBG

Fig. 11. Schematic diagram of ocean monitoring results using FBG

Fig. 12. Application of FBG for liquid level measurement

Fig. 13. Pressuremeasurementresultsofoilandgaspipelines

Fig. 14. Application of FBG for rock and soil pressure monitoring

|

Table 1. Advantages and disadvantages of various sensitization methods and applications

|

Table 2. Comparison of various temperature compensation methods

Set citation alerts for the article

Please enter your email address