Ting Yu, Jie Chen, Xixin Rao, Zixiang Zhang. High Temperature Wear Behaviors of Laser Cladded NiCrBSi Coatings[J]. Laser & Optoelectronics Progress, 2019, 56(10): 101601

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 56, Issue 10, 101601 (2019)

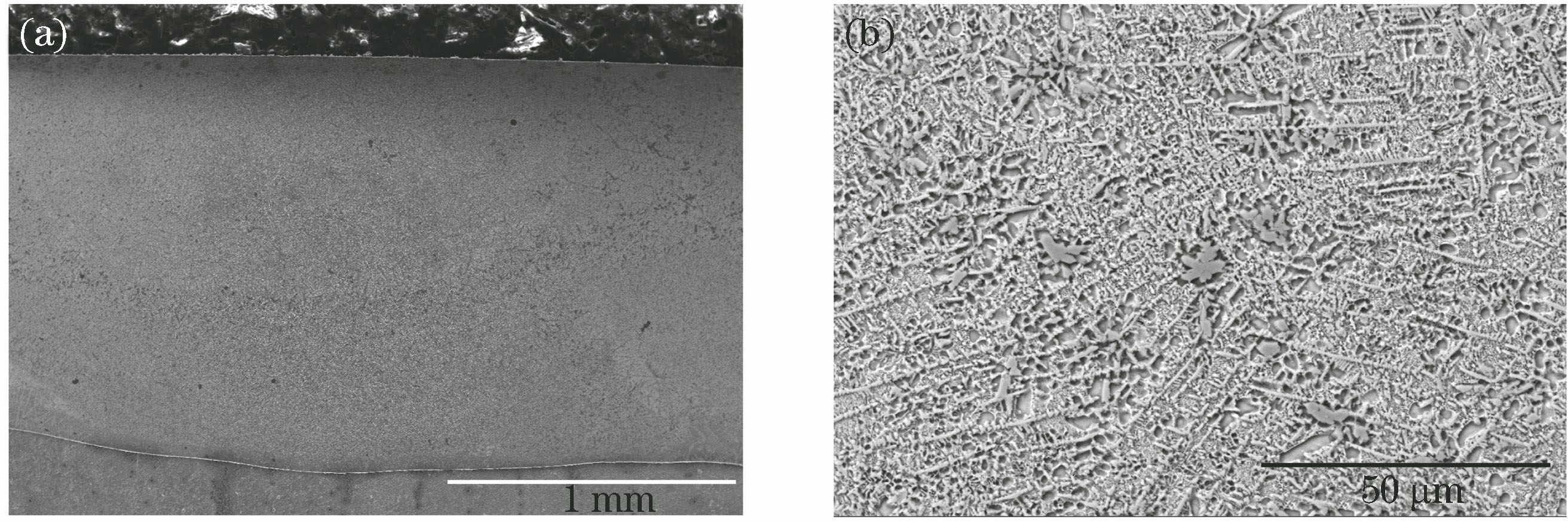

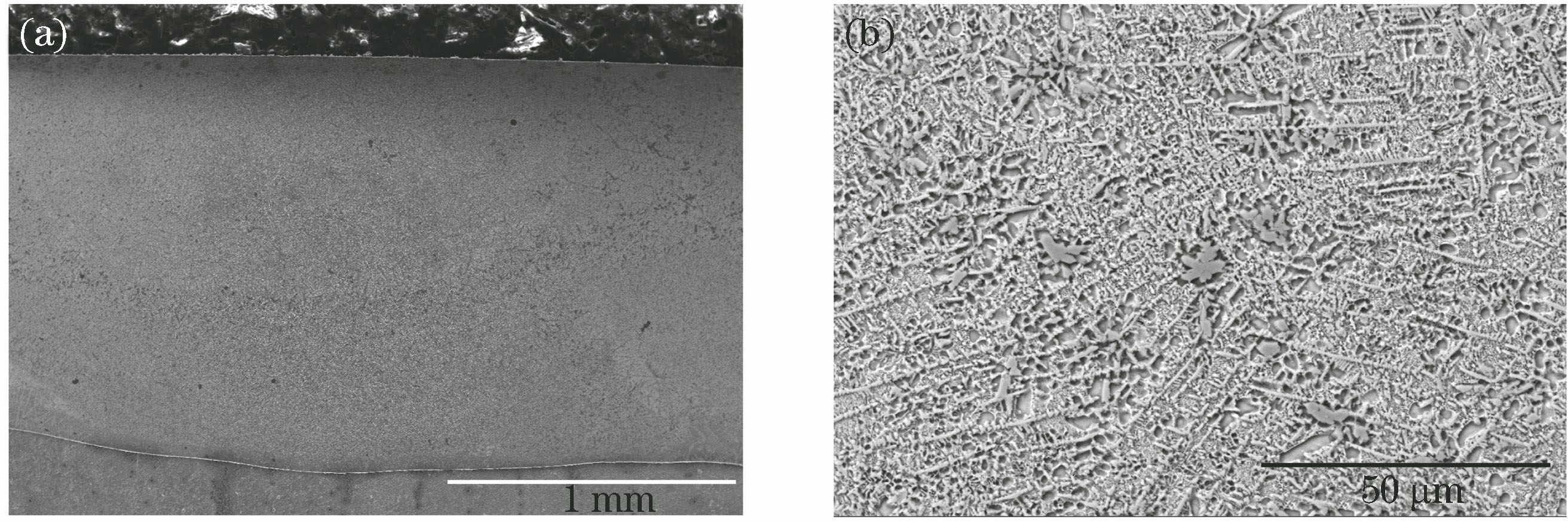

Fig. 1. Morphology of laser cladded Ni60 coating. (a) Macroscopic; (b) microscopic

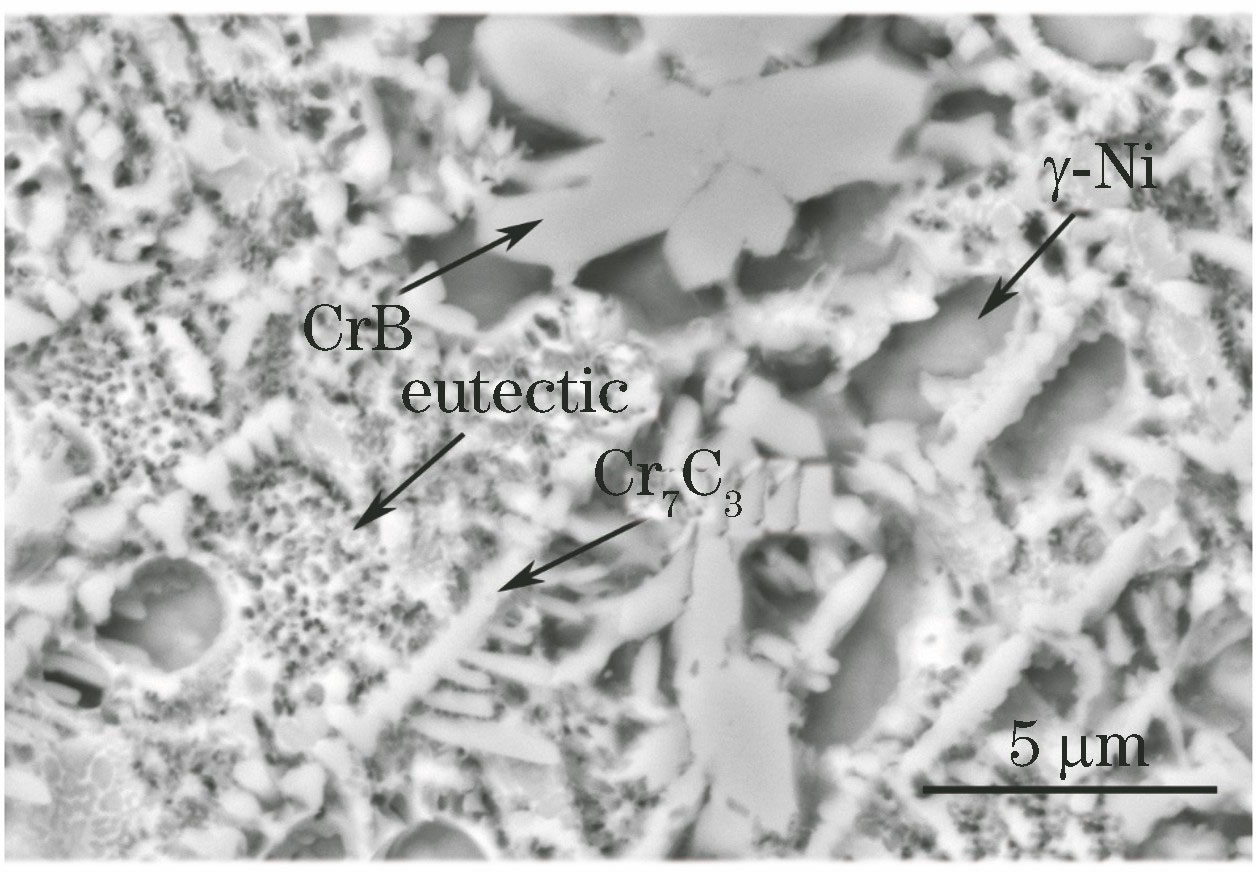

Fig. 2. Microstructure of Ni60 coating

Fig. 3. Microstructures of Ni60 coating after heat treatment. (a) 700 ℃; (b) 750 ℃

Fig. 4. XRD analysis results before and after heat treatment

Fig. 5. Microhardness before and after heat treatment

Fig. 6. Specimens after high temperature wear. (a) 700 ℃; (b) 750 ℃

Fig. 7. Mass loss of Ni60 coating versus temperature

Fig. 8. Surface morphologies of coating after high temperature wear. (a) 700 ℃; (b) 750 ℃

|

Table 1. Chemical compositions of substrate and Ni60 alloy (mass fraction, %)

|

Table 2. EDS analysis results of Cr7C3 before and after heat treatment (atomic fraction, %)

|

Table 3. EDS analysis results of CrB before and after heat treatment (atomic fraction, %)

Set citation alerts for the article

Please enter your email address