Shaodong Song, Yanyan Wang, Linsen Shu, Yajuan He. Optimization of 6061 Aluminum Alloy Laser Welding Process Based on RSM-PSO[J]. Laser & Optoelectronics Progress, 2022, 59(17): 1714004

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 59, Issue 17, 1714004 (2022)

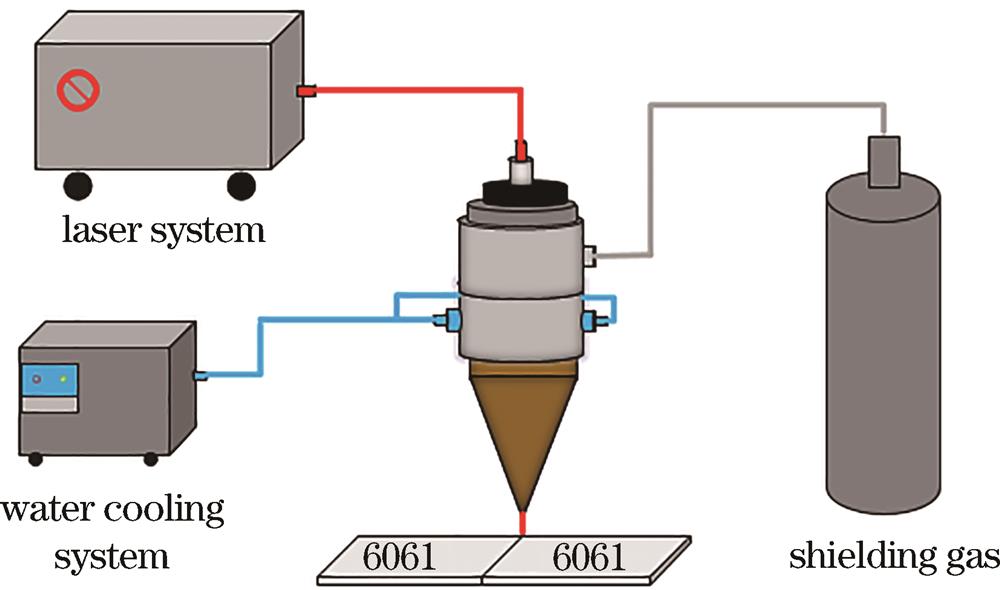

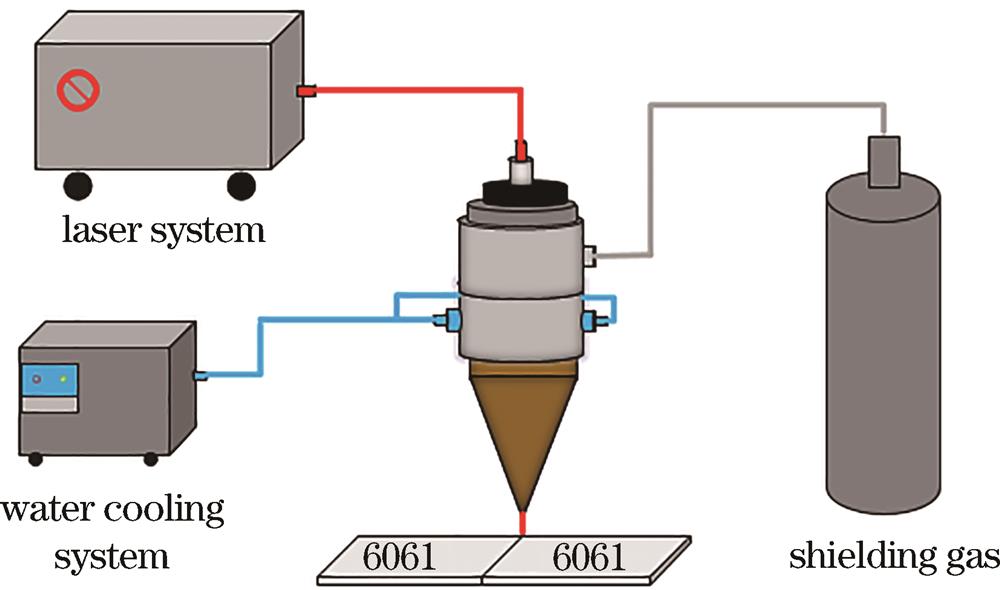

Fig. 1. Laser welding system

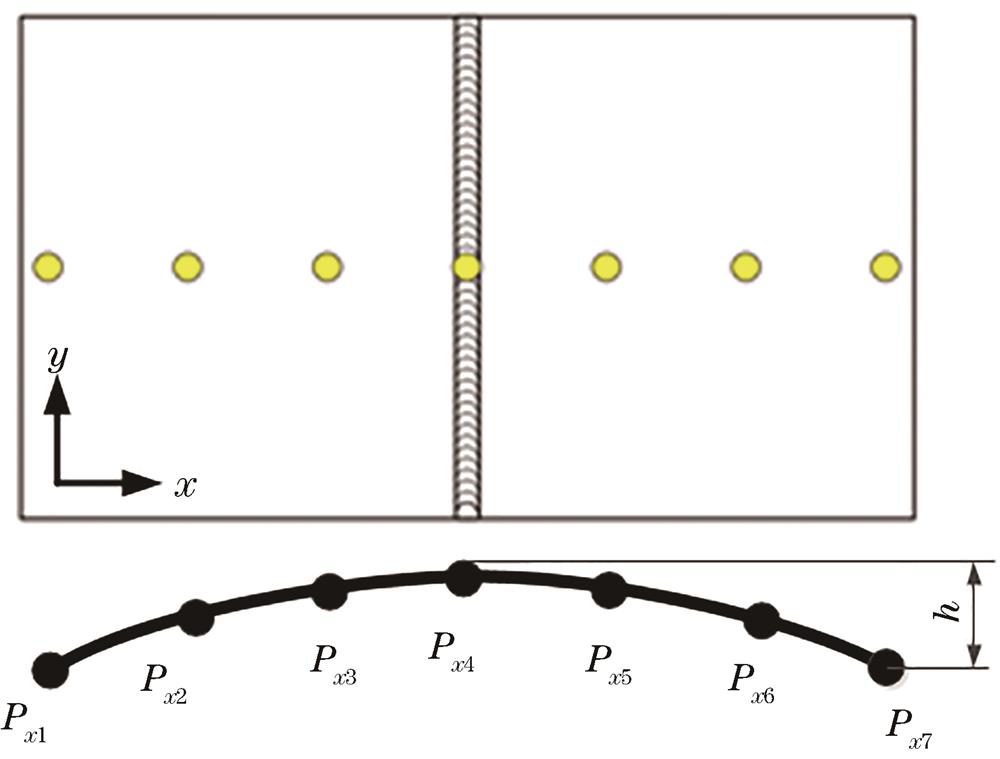

Fig. 2. Diagram of deformation measurement

Fig. 3. RSM-PSO optimization flow chart

Fig. 4. Normal probability residuals of the model. (a) Collapse model; (b) bending deformation model

Fig. 5. Weld section diagram

Fig. 6. Response value is the functional perturbation trend graph of the deviation of the central reference point. (a) Collapse depth; (b) bending deformation

Fig. 7. Interaction of process parameters on collapse depth. (a) Scanning speed and defocusing amount; (b) defocusing amount and laser power

Fig. 8. Interaction of process parameters on bending deformation. (a) Laser power and scanning speed; (b) laser power and defocusing amount

Fig. 9. Fitness curve

Fig. 10. Joint section views. (a) Optimal sample; (b) S9 sample; (c) S10 sample

|

Table 1. Experimental design and response

|

Table 2. Model analysis of variance table

Set citation alerts for the article

Please enter your email address