Huaian Yi, Runji Fang, Aihua Shu, Enhui Lu. Milling Surface Roughness Measurement Under Few-Shot Problem[J]. Laser & Optoelectronics Progress, 2022, 59(23): 2324001

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 59, Issue 23, 2324001 (2022)

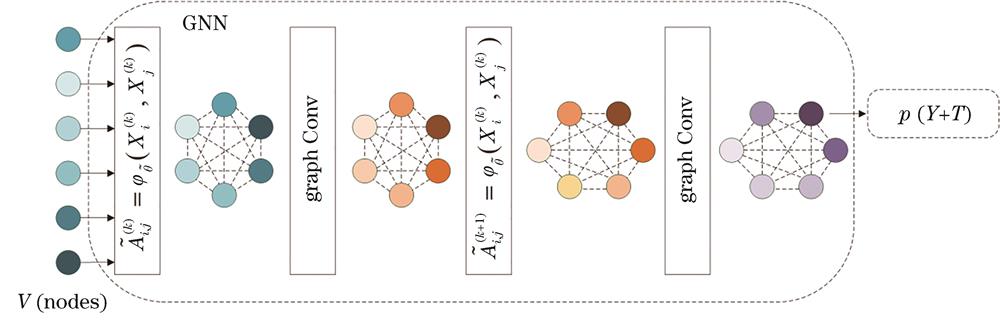

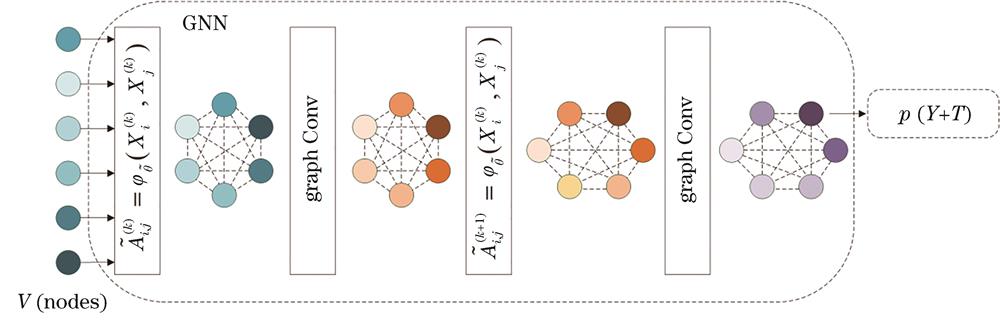

Fig. 1. GNN network structure diagram

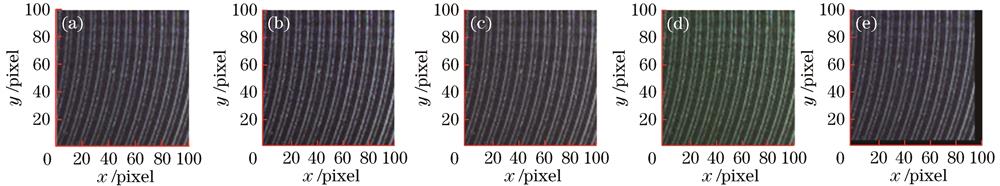

Fig. 2. Partial effect of data enhancement. (a) Original image; (b) adjusting contrast; (c) adjusting saturation; (d) adjusting hue; (e) translation

Fig. 3. Experimental design flow

Fig. 4. Machining machine and tool

Fig. 5. Experimental setup

Fig. 6. Texture orientation. (a) Left; (b) right

Fig. 7. Light and dark uneven distribution and reflection phenomenon

Fig. 8. Image pre-processing. (a) Clipping; (b) compression

Fig. 9. Experimental results. Loss function curves and accuracy curves of (a) (b) MAML and (c) (d) GNN

Fig. 10. Experimental results. Loss function curves and accuracy curves for cross-domain detection tasks (a) (b) A to B and (c) (d) B to A

|

Table 1. Material and processing parameters

|

Table 3. Sample classification and number statistics after data pre-processing

|

Table 4. Cross-domain detection tasks

|

Table 5. Test accuracy of MAML and GNN

|

Table 6. Test accuracy of cross-domain detection tasks A to B and B to A

Set citation alerts for the article

Please enter your email address