Yi Wang, Xiaojie Gong, Jia Cheng. Metal Workpiece Surface Defect Segmentation Method Based on Improved U-Net[J]. Laser & Optoelectronics Progress, 2023, 60(15): 1524001

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 60, Issue 15, 1524001 (2023)

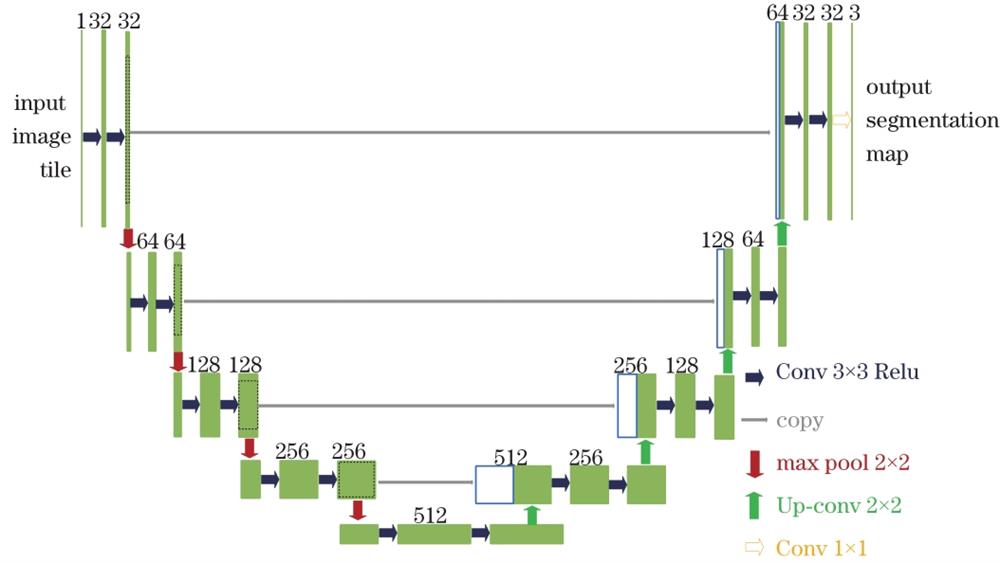

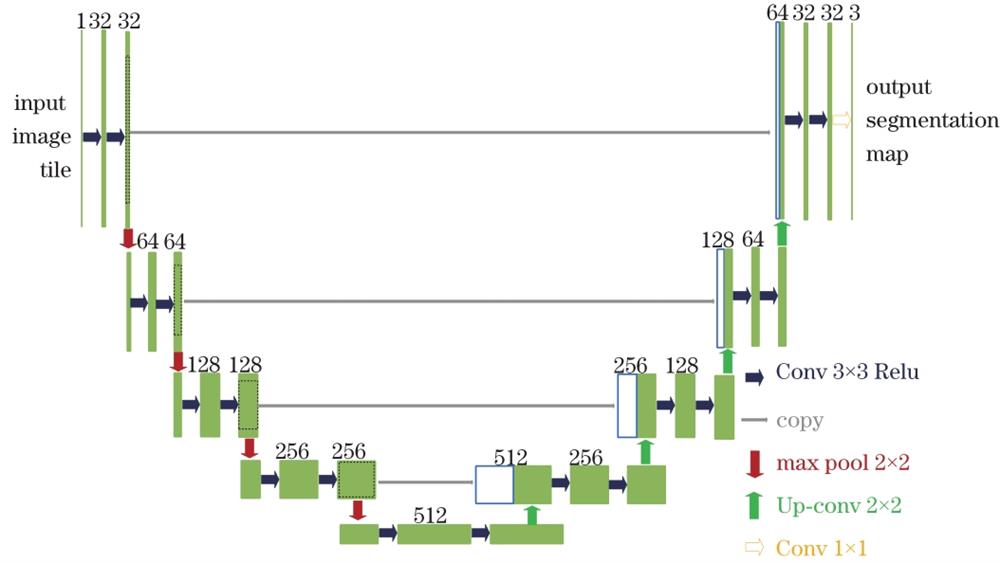

Fig. 1. U-net network structure

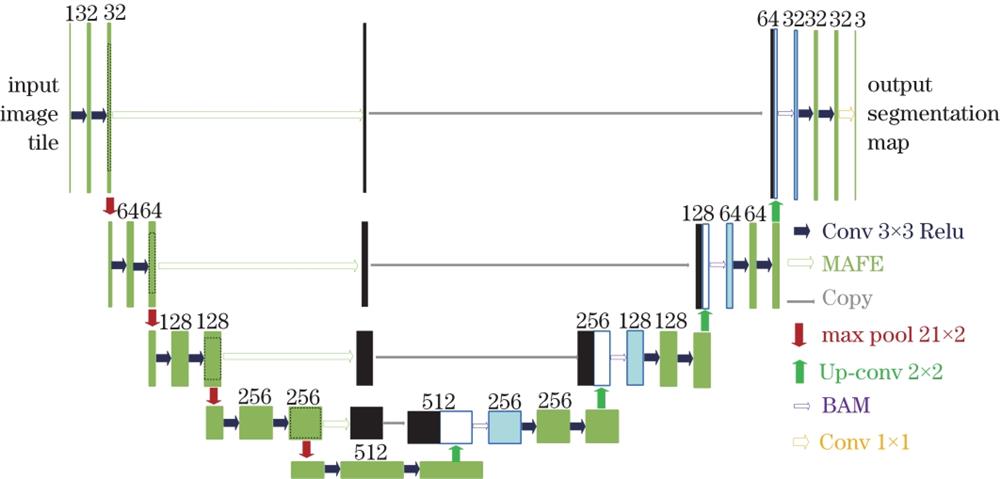

Fig. 2. Improved U-net network structure

Fig. 3. MAFE structure

Fig. 4. Bottleneck attention module

Fig. 5. Image acquisition visual platform

Fig. 6. Schematic diagram of cutting and filling. (a) Defect image; (b) image after processing

Fig. 7. Change curves of loss value

Fig. 8. Comparison of the segmentation effects. (a) Original images; (b) label; (c) U-net segmentation effect; (d) U-net-MAFE segmentation effect; (e) U-net-BAM segmentation effect; (f) U-net-MAFE-BAM segmentation effect

|

Table 1. Data comparison in the experimental network

Set citation alerts for the article

Please enter your email address