[2] Veiga C, Davim J P. Loureiro A J R. Properties and applications of titanium alloys: a brief review[J]. Reviews on Advanced Materials Science, 32, 134-148(2012).

[4] Martin G S, Albright C E, Jones T A. An evaluation of CO2 laser beam welding on a Ti3Al-Nb alloy[J]. Welding Journal, 74, 77-82(1995).

[13] Liu X X. Study on the control of laser welding deformation of titanium alloy thin sheet[D]. Changsha: Hunan University, 33-37(2014).

[14] Huang S. Study on measurement of temperature field and weld seam's characteristics in laser welding of TA15 titanium alloy[D]. Wuhan: Wuhan University of Technology, 34-45(2012).

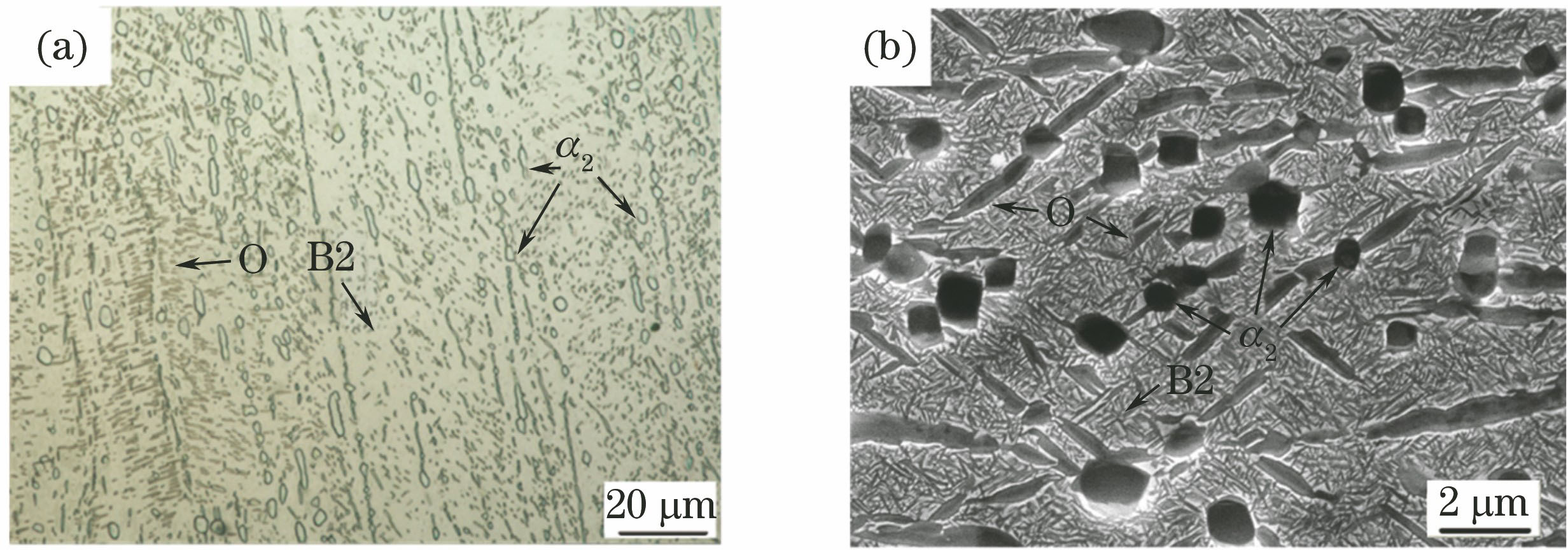

[15] Dong Z J. Study on characteristics of laser welded Ti2AlNb-based alloys[D]. Harbin: Harbin Institute of Technology, 18-23(2012).