Yanlong Chen, Linsen Shu, Shaodong Song. Study on Laser Additive Welding Process and Properties of 304L/316 Dissimilar Steel Sheets[J]. Laser & Optoelectronics Progress, 2022, 59(23): 2314005

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 59, Issue 23, 2314005 (2022)

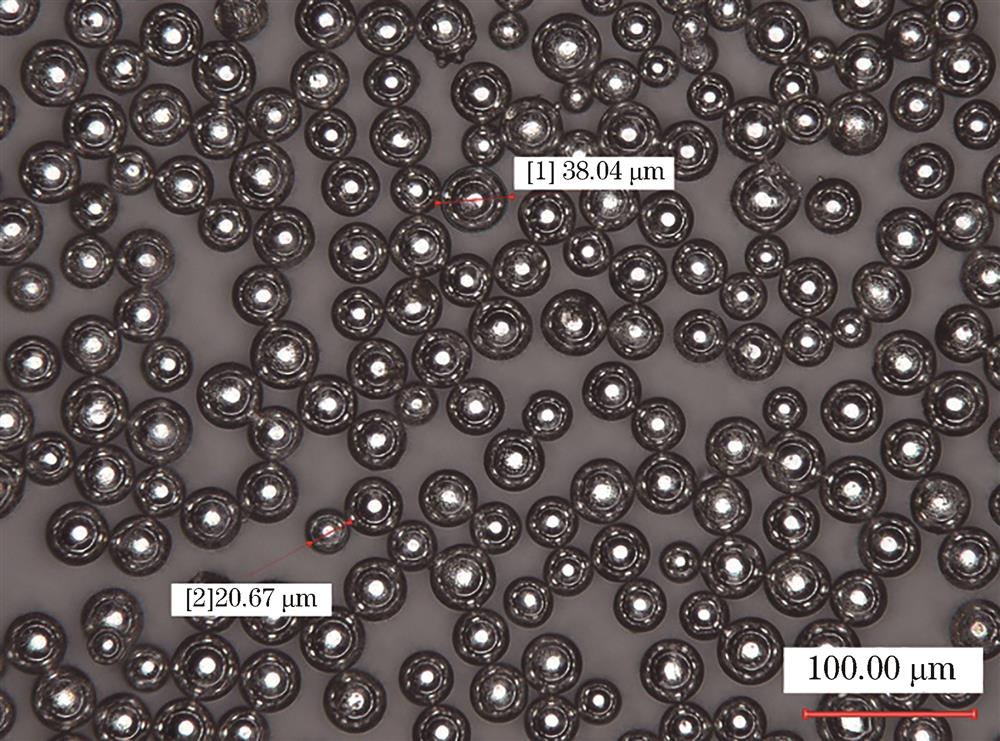

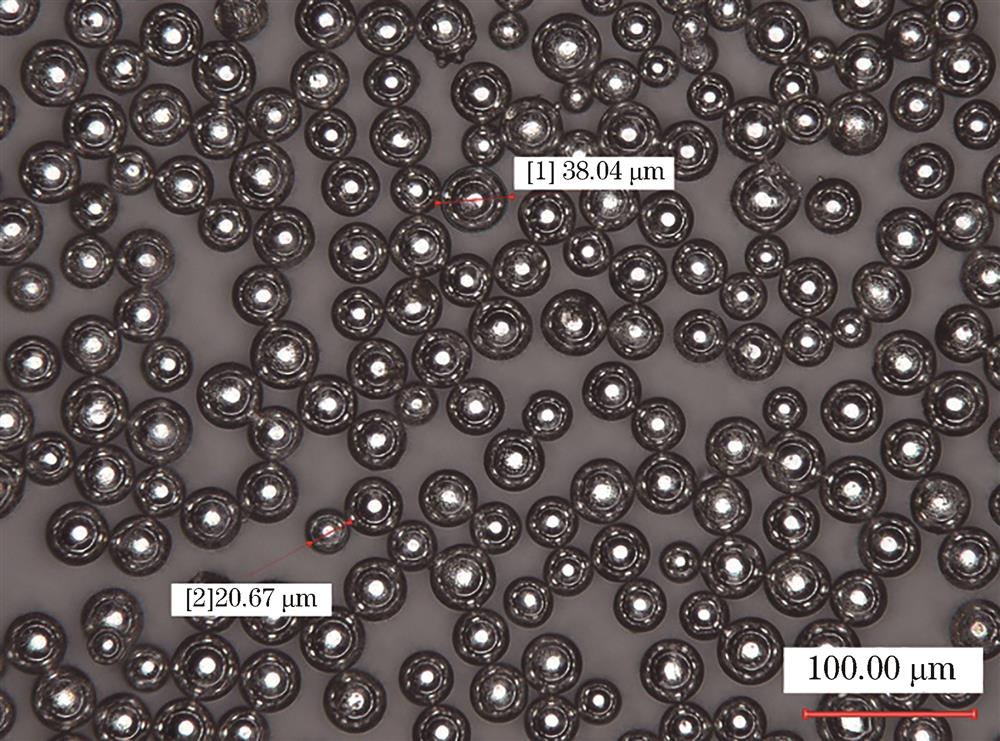

Fig. 1. Powder morphology

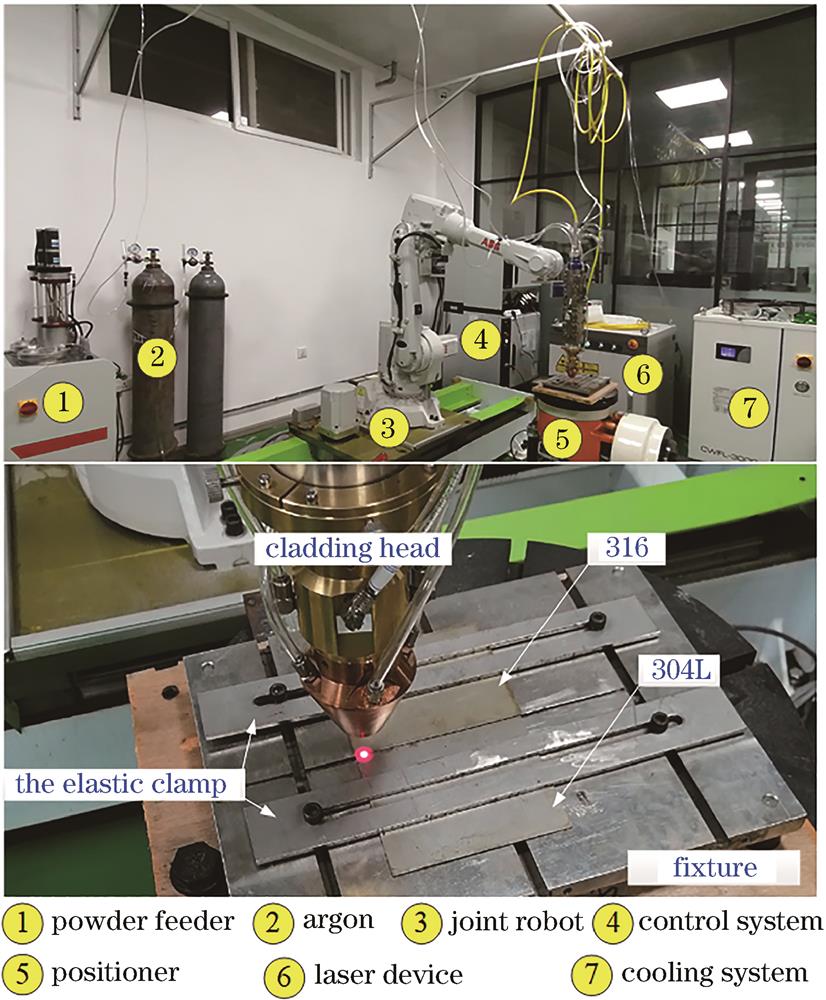

Fig. 2. Experimental equipment and clamping styles

Fig. 3. Sheet deformation measurement scheme. (a) Schematic diagram of measuring points; (b) schematic diagram of calculation method

Fig. 4. Tensile specimen and experimental equipment. (a) Shape and size of tensile specimen; (b) schematic diagram of tensile test

Fig. 5. Surface morphologies of samples under different process parameters

Fig. 6. Section profiles of joints

Fig. 7. Morphologies of specimen after tensile test

Fig. 8. Effect of defocus amount on angular deformation

Fig. 9. Influence of laser power on bending deformation

Fig. 10. Influence of scanning speed on bending deformation

Fig. 11. Effect of defocus amount on tensile strength

Fig. 12. Grey correlation degree

Fig. 13. Microstructure of 304L/316 additive welded joint

Fig. 14. Validation experiment. (a) Macroscopic morphology of specimen after stretching; (b) tensile mechanical properties of specimens

|

Table 1. Mechanical properties of 304L stainless steel and 316 stainless steel

| ||||||||||||||||||||||||||||||||||||||||||||

Table 2. Chemical composition of 304L stainless steel and 316 stainless steel

| |||||||||||||||||||||||

Table 3. Process parameters and their ranges

|

Table 4. L9 orthogonal array used for laser welding trials and responses

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Table 5. Range analysis

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Table 6. Grey correlation coefficient

|

Table 7. Results of angular deformation and bending deformation

Set citation alerts for the article

Please enter your email address