Peng Zhang, Yu Zhang, Kun Cui, Jiaxing Ma, Song Mei. Inspection of Wind Turbine Blades Based on Modified Thermoelastic Stress Analysis Using Thermal Detection of Infrared Radiation[J]. Laser & Optoelectronics Progress, 2023, 60(15): 1512004

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 60, Issue 15, 1512004 (2023)

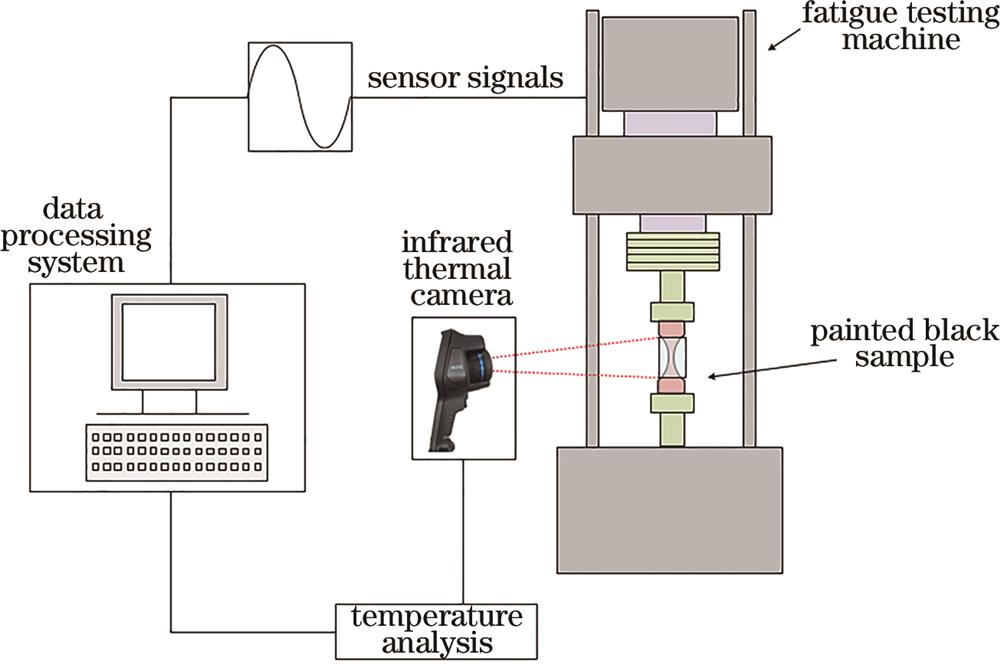

Fig. 1. Overall scheme of the experiment

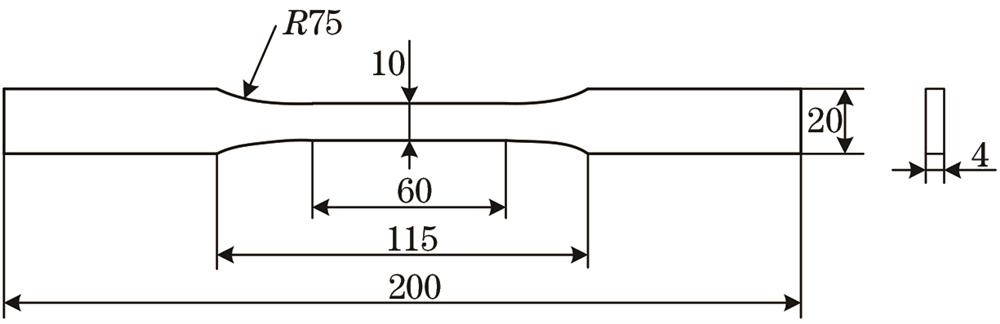

Fig. 2. Sample size

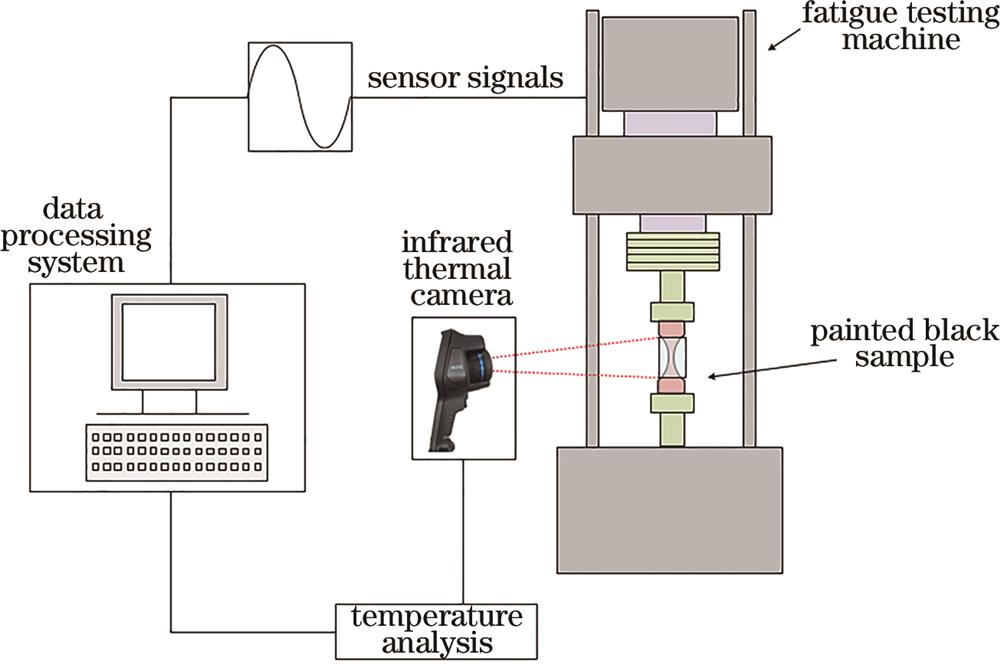

Fig. 3. Diagram of experimental setup

Fig. 4. Temperature change of sample monitoring point under 1 Hz frequency

Fig. 5. Comparison of temperature difference and stress between experiment and modified model

Fig. 6. Comparison of modified model results with reference results

Fig. 7. Wind turbine blade model based on BLADE

Fig. 8. BLADED wind turbine model

Fig. 9. Blade thrust at rated wind speed

Fig. 10. Finite element model of wind turbine blade

Fig. 11. Diagram of blade stress

Fig. 12. Sum of principal stresses of wind turbine blade

Fig. 13. Temperature of wind turbine blade

|

Table 1. Basic parameters of epoxy resin

|

Table 2. Basic parameters of wind turbine blades

|

Table 3. Basic parameters of wind turbine

|

Table 4. Material properties

Set citation alerts for the article

Please enter your email address