Hao Zhang, Yaqing Hou, Yazhou He, Haohao Kong, Fafa Li, Hang Su. Influence of Cr Content on the Microstructure and Properties of Laser Powder Bed Fusion FeCr Alloy[J]. Laser & Optoelectronics Progress, 2023, 60(13): 1314004

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 60, Issue 13, 1314004 (2023)

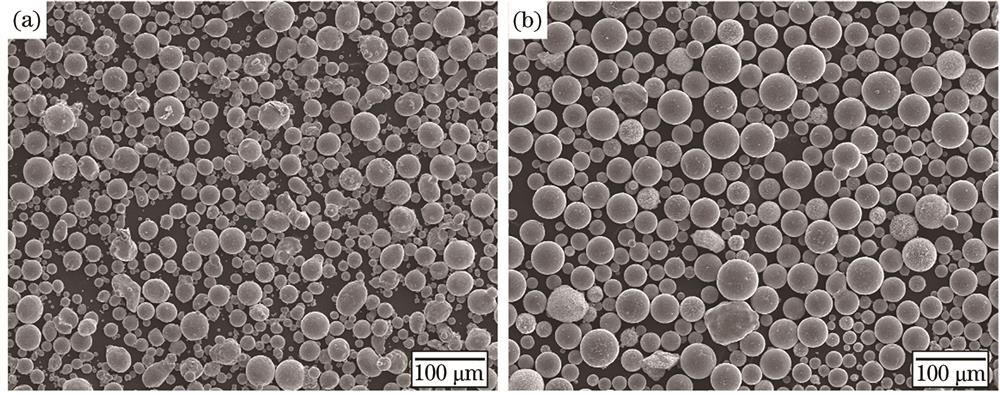

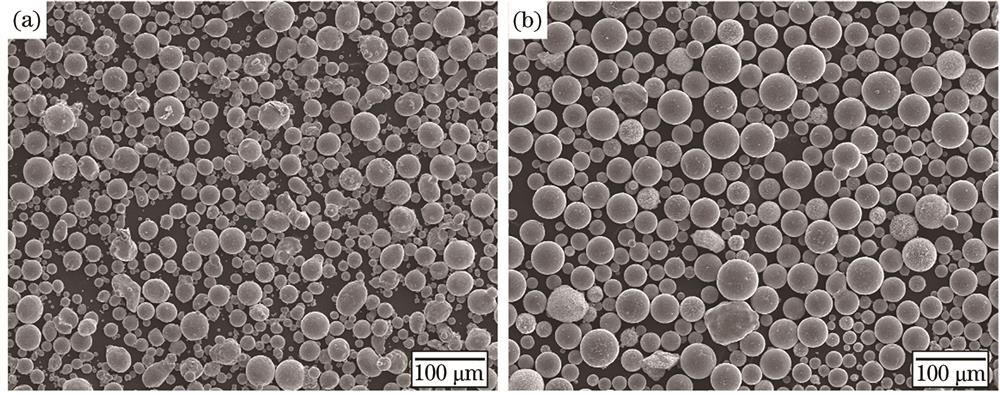

Fig. 1. SEM morphologies of powders. (a) Fe powder; (b) Cr powder

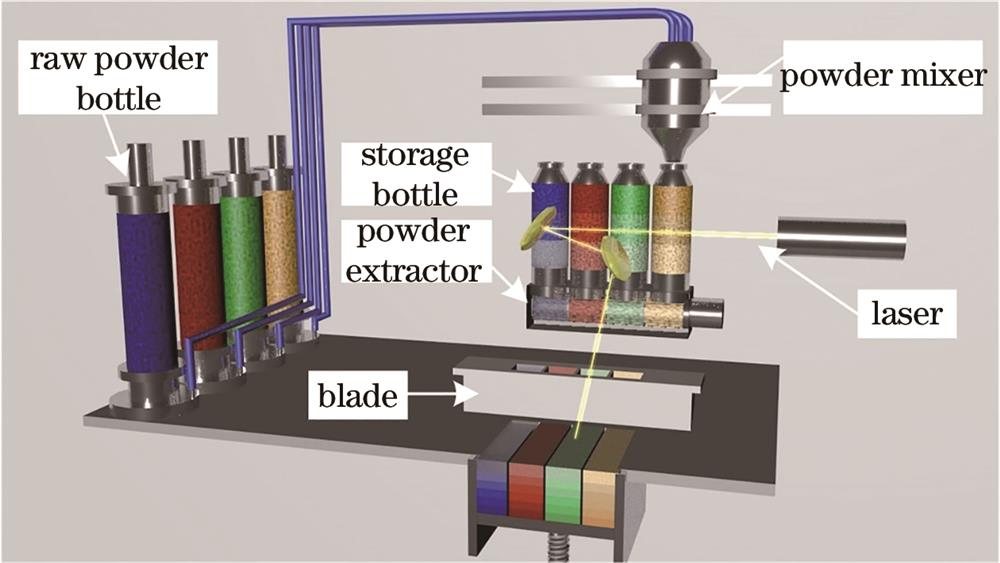

Fig. 2. Schematic diagram of the high throughput synthesis platform

Fig. 3. Fe-Cr alloy samples. (a) Photo of FeCr gradient composition sample; (b) laser scanning strategy time

Fig. 4. μ-XRF results of FeCr gradient composition samples. (a) Cr element mass fraction; (b) deviation of Cr element mass fraction

Fig. 5. XRD patterns of FeCr gradient composition specimens

Fig. 6. OM morphology of FeCr gradient composition specimens. (a) Sample cross section; (b) pure iron; (c) Fe2Cr; (d) Fe4Cr; (e) Fe6Cr; (f) Fe8Cr; (g) Fe10Cr; (h) Fe12Cr; (i) Fe14Cr; (j) Fe16Cr; (k) Fe18Cr; (l) Fe20Cr

Fig. 7. OM morphology at high magnification from pure Fe to Fe10Cr. (a) Pure Fe; (b) Fe2Cr; (c) Fe4Cr; (d) Fe6Cr; (e) Fe8Cr; (f) Fe10Cr

Fig. 8. Thermal conductivity of FeCr alloy with different Cr element mass fractions

Fig. 9. Phase diagram of FeCr binary alloy

Fig. 10. Microhardness of specimens with FeCr gradient composition

|

Table 1. Powder particle size distribution

Set citation alerts for the article

Please enter your email address