Minhui Zheng, Zhenzhong Wang, Xuepeng Huang, Lucheng Li. Wear Detection Method for Flexible Polishing Bonnet Tools Based on Improved Iterative Closest Point Splicing Algorithm[J]. Laser & Optoelectronics Progress, 2023, 60(16): 1612001

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 60, Issue 16, 1612001 (2023)

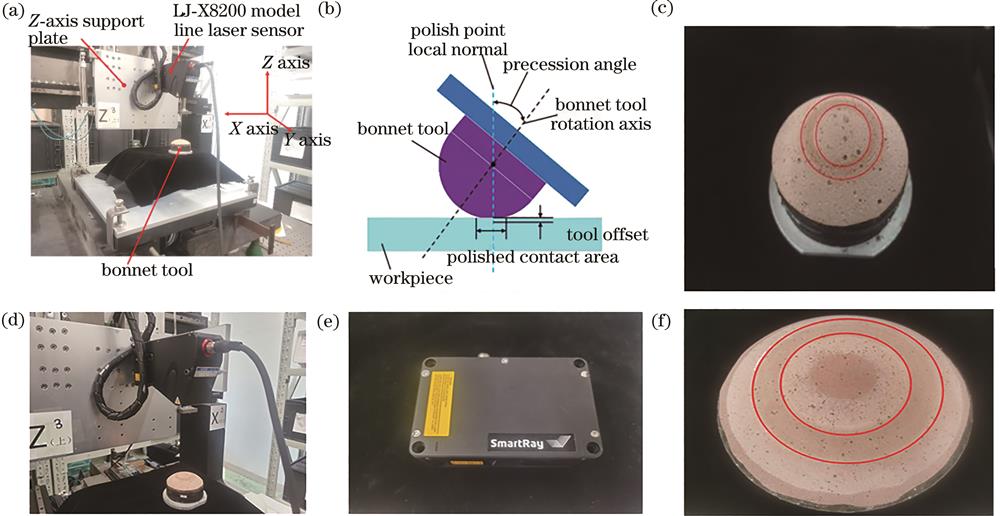

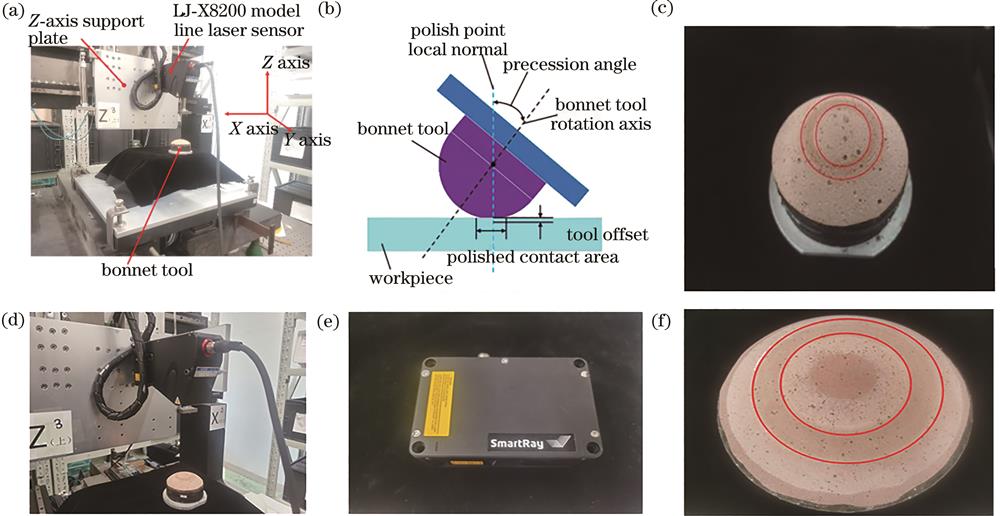

Fig. 1. Schematic of data acquisition platform detection. (a) Three-axis motion platform; (b) schematic of bonnet polishing precession; (c) R40 bonnet tool; (d) KEYENCE LJ-X8200 large range line laser sensor;(e)SmartRay ECCO95.020 small range line laser sensor;(f)R160 bonnet tool

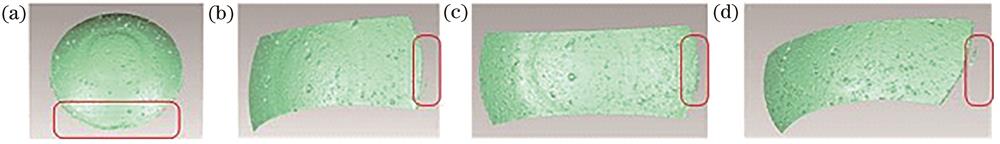

Fig. 2. R40 bonnet tool dataset

Fig. 3. Data preprocessing effect

Fig. 4. Three frames of adjacent point clouds

Fig. 5. Specific process of the algorithm

Fig. 6. Flow chart of bonnet wear detection algorithm

Fig. 7. Registration effect of R40 bonnet tool. (a) PFH-ICP registration algorithm; (b) FPFH-ICP registration algorithm; (c) 3DSC-ICP registration algorithm; (d) NDT-ICP registration algorithm; (e) proposed crude registration -ICP; (f) proposed algorithm

Fig. 8. Registration effect of R160 bonnet tool. (a) PFH-ICP registration algorithm; (b) FPFH-ICP registration algorithm; (c) 3DSC-ICP registration algorithm; (d) NDT-ICP registration algorithm; (e) proposed crude registration-ICP; (f) proposed algorithm

Fig. 9. Bonnet tool point cloud obtained by one-time full scanning

Fig. 10. Contour plot in Y direction obtained by the large range line laser sensor

Fig. 11. Contour plot in X direction obtained by the large range line laser sensor

Fig. 12. Contour plot in Y direction obtained by the proposed algorithm

Fig. 13. Contour plot in X direction obtained by the proposed algorithm

|

Table 1. Motion parameters of three-axis platform

|

Table 2. Parameters of KEYENCE LJ-X8200 large range line laser sensor

|

Table 3. Parameters of SmartRay ECCO95.020 small range line laser sensor

|

Table 4. Data preprocessing result

|

Table 5. Average rotation error of two registrations for R40 bonnet tool

|

Table 6. Average rotation error of two registrations for R160 bonnet tool

|

Table 7. Average translation error of two registrations for R40 bonnet tool

|

Table 8. Average translation error of two registrations for R160 bonnet tool

|

Table 9. Average registration completion time of two registrations for R40 bonnet tool

|

Table 10. Average registration completion time of two registrations for R160 bonnet tool

|

Table 11. Wear depth of R40 bonnet tool

Set citation alerts for the article

Please enter your email address