Jun Fu, Jiajia Yin, Junming Shao, Bin Fan, Jiang Bian, Junfeng Du. Preparation and Space Irradiation Resistance of Composite Thin Film Diffractive Lens[J]. Laser & Optoelectronics Progress, 2023, 60(13): 1316018

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 60, Issue 13, 1316018 (2023)

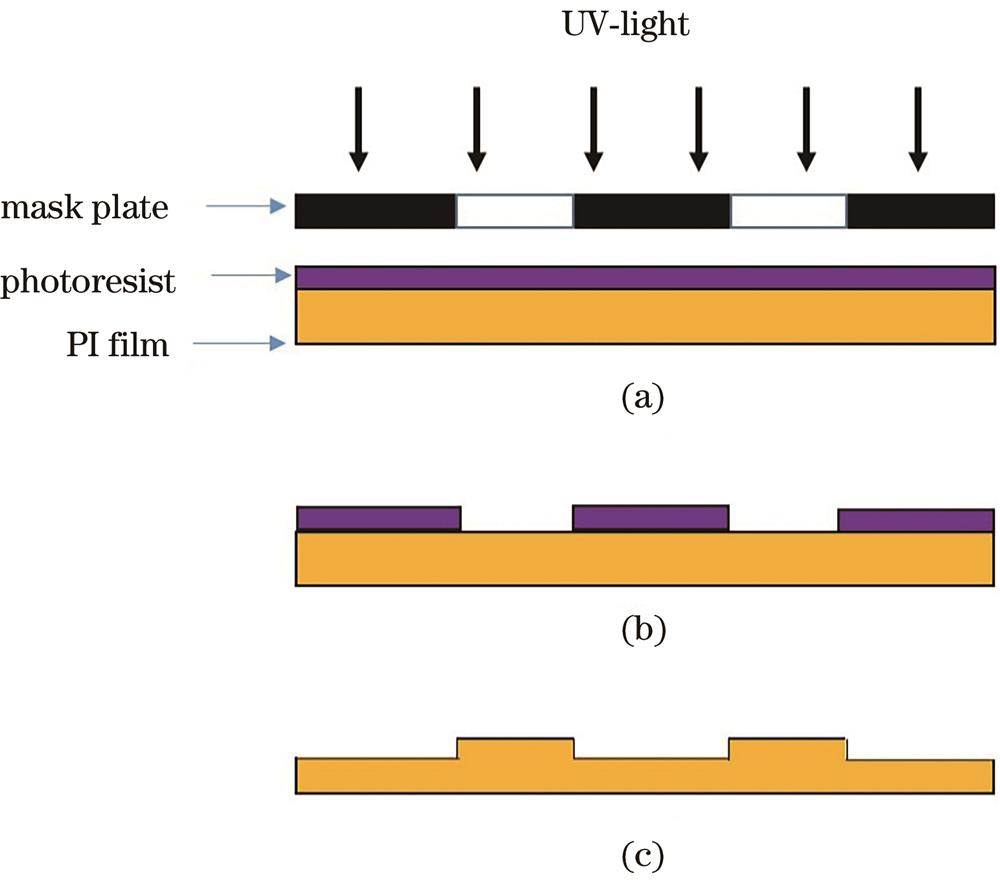

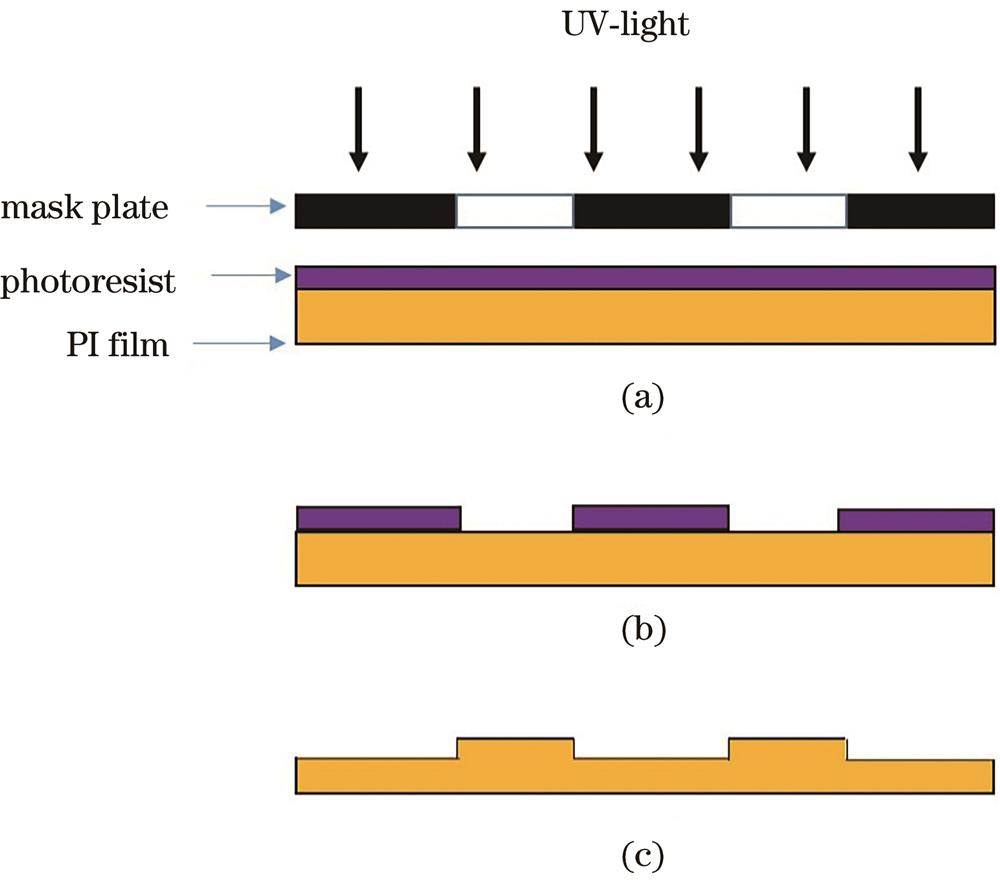

Fig. 1. Illustration of two steps Fresnel diffractive lens preparation process. (a) Ultraviolet exposure; (b) developing; (c) etching

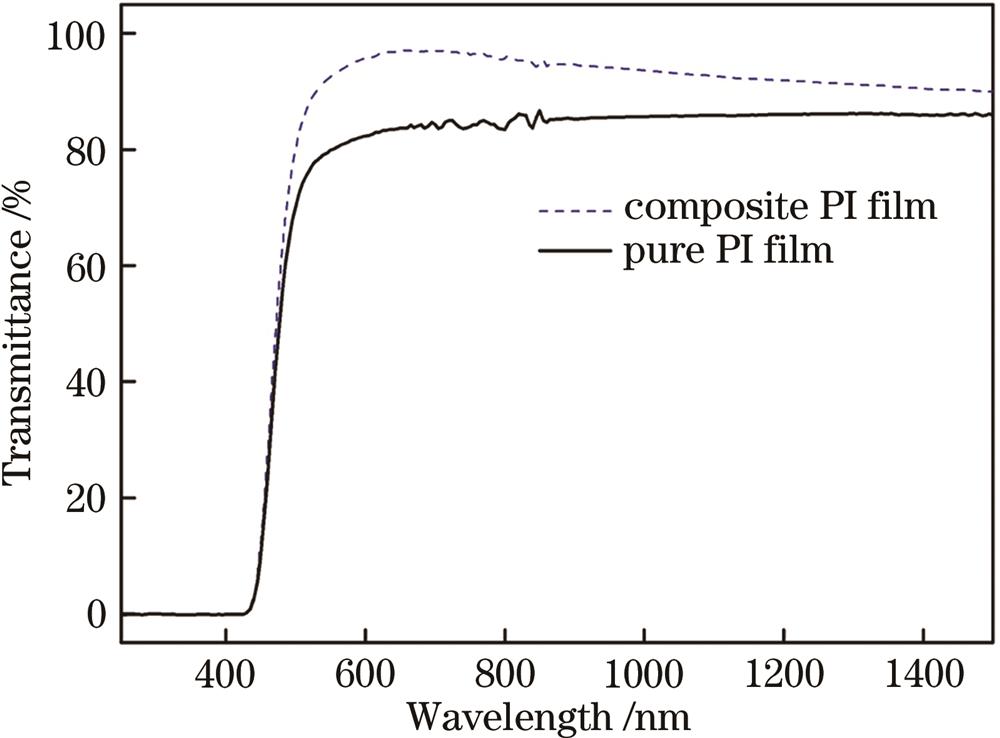

Fig. 2. Transmittance comparison of composite PI film and pure PI film (thickness of film is 25 μm)

Fig. 3. Transmission wavefront test results of PI film lens (pure film, Φ75 mm, h=25 μm, ring fixation test)

Fig. 4. Comparison of TG analysis and test results between composite PI film and pure PI film

Fig. 5. Prepared two steps Fresnel diffractive lens. (a) Picture; (b) diffraction behavior of film diffractive lens to He-Ne laser; (c) illustration of Fresnel diffractive lens; (d) partial test results

|

Table 1. Carbon residue rate results of composite PI film and pure PI film

|

Table 2. Average transmittance of composite PI film before and after a certain amount of proton, electron, and space UV radiation

Set citation alerts for the article

Please enter your email address