Shuaikang Cheng, Di Wu, Guohu Luo, Yongxiang Hu. Effect of Pulse Duration on Laser-Induced Forward Transfer of Microdroplets[J]. Laser & Optoelectronics Progress, 2023, 60(19): 1914001

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 60, Issue 19, 1914001 (2023)

Fig. 1. Schematic of LIFT (a) process and (b) experimental setup

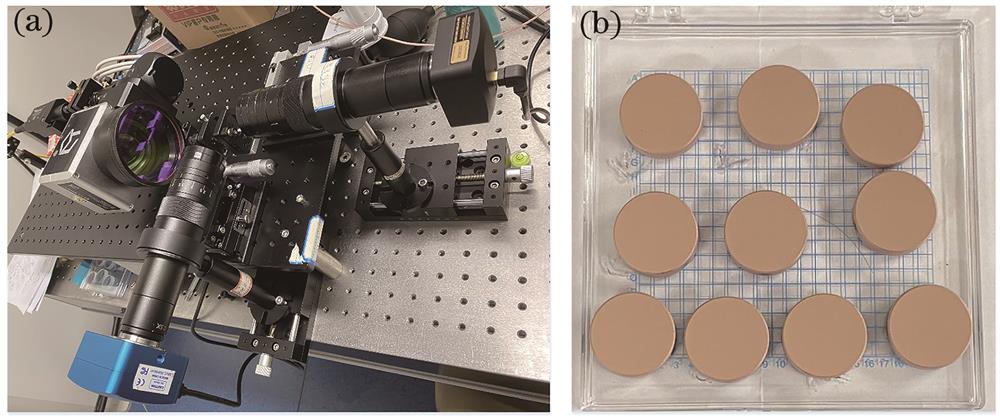

Fig. 2. Physical pictures of experimental (a) setup and (b) samples

Fig. 3. SEM images of donor copper film and receiving substrate under different pulse durations. (a) 14 ns; (b) 20 ns; (c) 30 ns; (d) 50 ns; (e) 100 ns

Fig. 4. Processing map of LIFT under different pulse durations

Fig. 5. SEM images of deposition microdroplets under different laser energy flux densities at pulse durations of 14 ns and 50 ns (sample rotated 55°). (a) 14 ns; (b) 50 ns

Fig. 6. Schematic of formation of deposition microdroplet morphology under short pulse duration. (a) Single droplet; (b) stacked droplet; (c) fused droplet

Fig. 7. Images of copper film and deposition microdroplet ablated by 20 ns, 4916 mJ/cm2 laser. (a) SEM image of copper film; (b) SEM image of deposition microdroplet; (c) confocal microscopy image of deposition microdroplet

Fig. 8. Material transfer rates under different pulse durations

Fig. 9. Large-scale microdroplet array. (a) SEM image of microdroplet array; (b) mesh matching diagram of deposition microdroplet and ablative pit; (c) landing errors of

|

Table 1. Experimental scheme of LIFT

Set citation alerts for the article

Please enter your email address