Peng Liu, Zhikai Chen, Quanming Jin, Qinghai Zhu. Microstructure and Corrosion Behaviors of 316L Coating Fabricated by Laser Cladding[J]. Laser & Optoelectronics Progress, 2020, 57(3): 031402

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 57, Issue 3, 031402 (2020)

Fig. 1. Surface of 316L coating when energy density is less than or equal to 19 J·mm-2

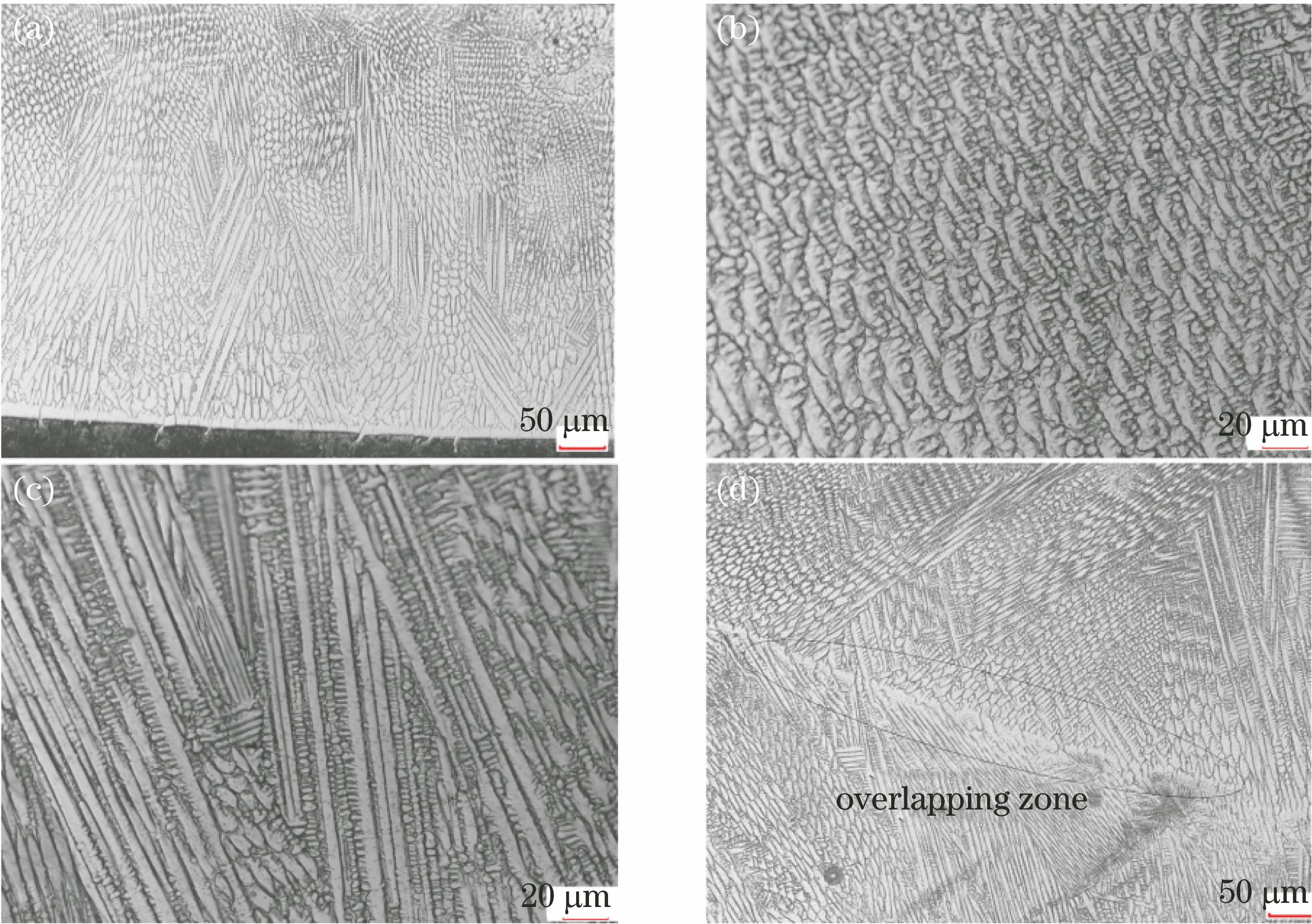

Fig. 2. Microstructures of 316L coating. (a) Cross-sectional morphology; (b) microstructure of cellular crystal; (b) microstructure of columnar crystal; (d) microstructure of overlapping zone

Fig. 3. Relationship between hardness and energy density of 316L coating and schematic of microstructures. (a) Hardness of coating under different energy densities; (b)-(d) microstructures under energy densities of 19, 28, and 44 J·mm-2, respectively

Fig. 4. SEM image of 316L coating under magnification of 3000

Fig. 5. Polarization curves. (a) Substrate; (b) 316L coating

Fig. 6. Corrosion morphologies of substrate and 316L coating after suffering acid salt spray tests with different time. (a) Substrate after 16 h; (b) 316L coating after 16 h; (c) 316L coating after 96 h; (d) 316L coating after 350 h

Fig. 7. Micro corrosion morphologies of 316L coating after suffering acid salt spray for 350 h. (a) 100×; (b) 500×

|

Table 1. Elemental compositions of 316L metal powder (mass fraction, %)

|

Table 2. Processing parameters of 316L metal powder

|

Table 3. Elemental contents of P1 and P2 points (mass fraction, %)

Set citation alerts for the article

Please enter your email address