Jiaqi Xue, Xiaohui Chen, Liming Lei. Effects of Microstructure on Mechanical Properties of GH3536 Alloy Fabricated by Selective Laser Melting[J]. Laser & Optoelectronics Progress, 2019, 56(14): 141401

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 56, Issue 14, 141401 (2019)

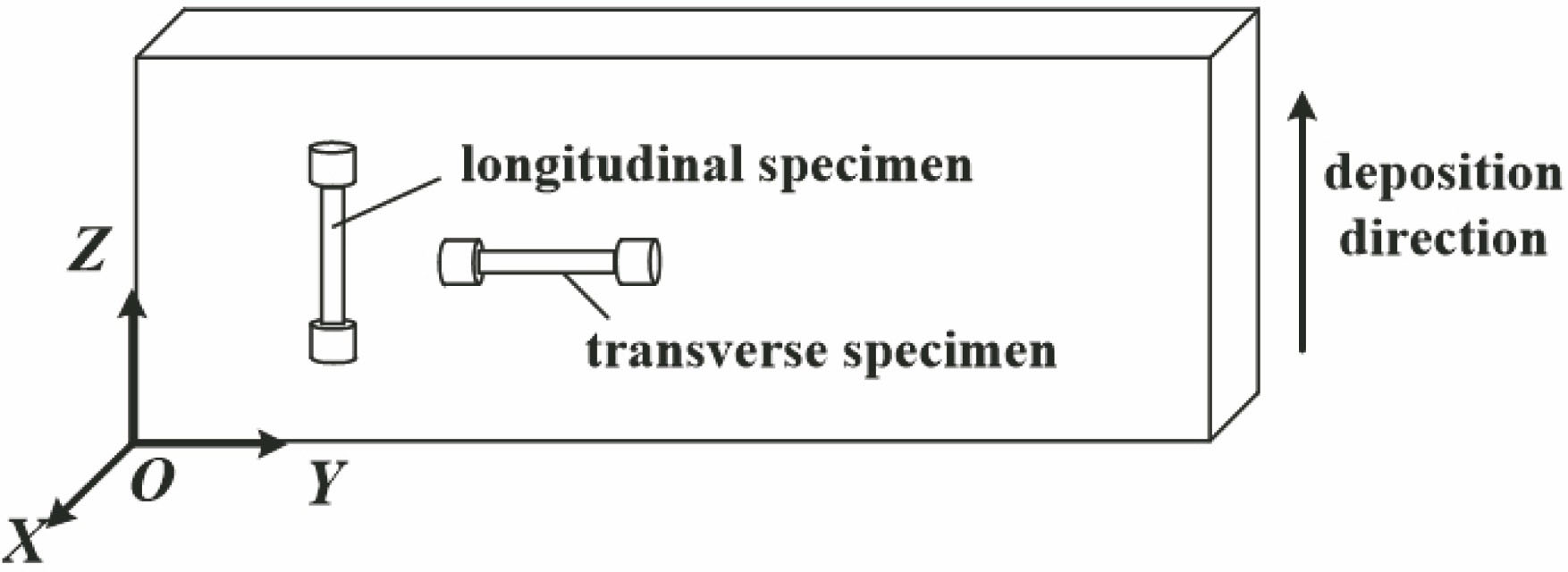

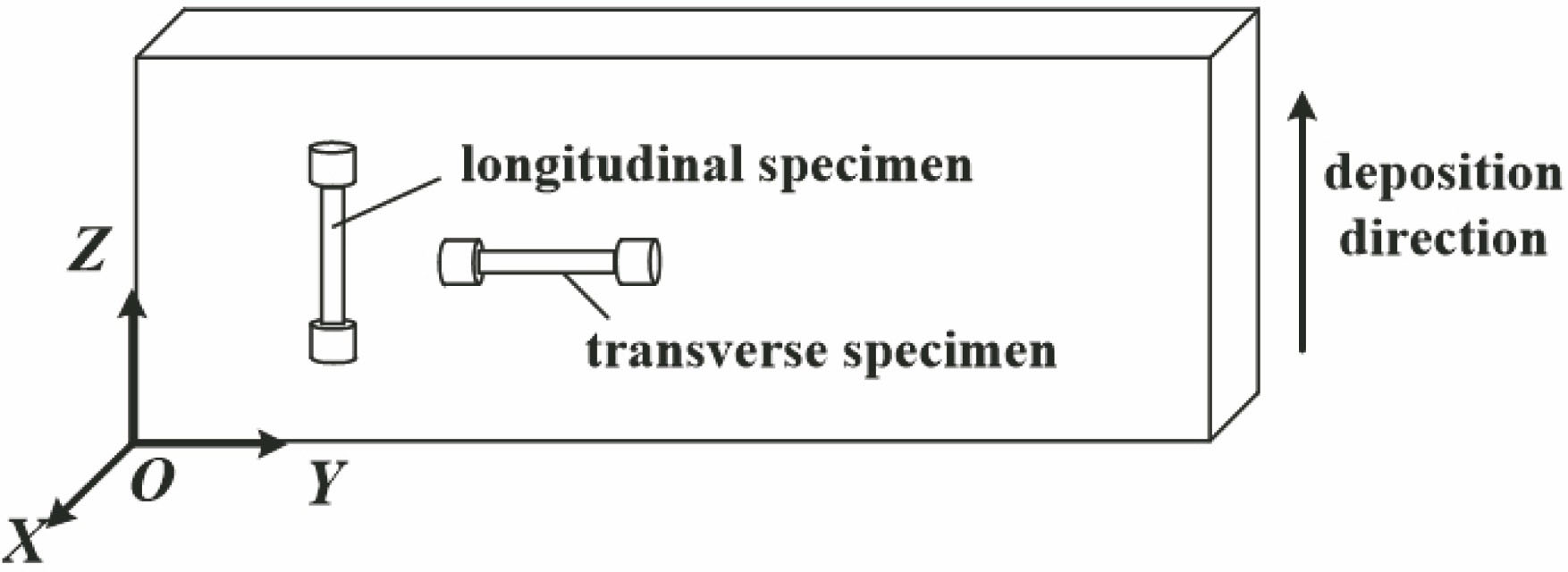

Fig. 1. Direction illustration of mechanica property specimens

Fig. 2. Grain morphologies of SLM GH3536. (a) Longitudinal and (b) transverse sections of specimen A; (c) longitudinal and (d) transverse sections of specimen B

Fig. 3. XRD pattern of SLM GH3536

Fig. 4. Precipitation of SLM GH3536. (a) Transmission photograph; (b) electron diffraction patterns; (c) scanning photograph; (d) EDS pattern

Fig. 5. Microstructures of SLM GH3536. (a) Longitudinal and (b) transverse sections of specimen A; (c) longitudinal and (d) transverse sections of specimen B

Fig. 6. Tensile fractures of SLM GH3536 alloy at room temperature. (a) Longitudinal and (b) transverse fractures of specimen A; (c) longitudinal and (d) transverse fractures of specimen B

Fig. 7. Fractures of SLM GH3536 alloy at high temperature. (a) Longitudinal and (b) transverse fractures of specimen A; (c) longitudinal and (d) transverse fractures of specimen B

Fig. 8. Fracture sections of SLM GH3536 alloy at high temperature. (a) Low magnification photograph; (b) high magnification photograph

|

Table 1. Chemical composition of SLM GH3536 specimen (mass fraction, %)

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||

Table 2. Room temperature tensile property and high temperature endurance performance of SLM GH3536 alloy

Set citation alerts for the article

Please enter your email address