Yanyan Liu, Lü Fei, Meng Xiao, Xuesong Gao, Jun Zhou, Changxing Du. Microstructures and Property of Aluminum Alloy Doped with Copper Powder Fabricated by Selective Laser Melting[J]. Laser & Optoelectronics Progress, 2023, 60(1): 0114012

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 60, Issue 1, 0114012 (2023)

Fig. 1. Morphology and particle size distribution of basic aluminum alloy powder. (a) Morphology; (b) size distribution

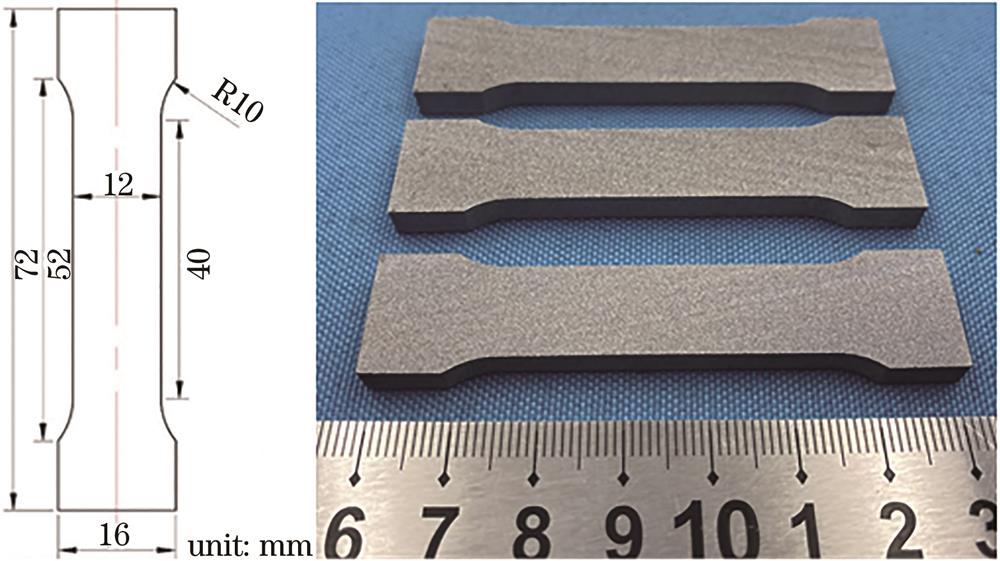

Fig. 2. Dimension and physical drawing of tensile test sample

Fig. 3. XRD patterns of different samples. (a) 10°-90°; (b) 64°-67°

Fig. 4. Microstructures of different types of samples. (a) C0; (b) C1; (c) C2; (d) C3

Fig. 5. Microstructure analysis of C2 sample. (a) Microstructure; (b) grain orientation

Fig. 6. Al grain size distribution diagram of samples with different mass fractions of Cu powder. (a) C0; (b) C1; (c) C2; (d) C3

Fig. 7. Tensile test results of different types of samples. (a) Stress-strain curves; (b) tensile strength and elongation

Fig. 8. SEM images of fracture surface of C0 and C2 tensile samples. (a) C0; (b) C2

Fig. 9. SEM images of fracture surface of C3 tensile sample

| |||||||||||||||

Table 1. Physical and chemical parameters of copper powder

|

Table 2. Composition of commercial Al250C aluminum alloy powder

Set citation alerts for the article

Please enter your email address