Yining Liu, Weili Fan, Xiaohan Hou, Zhicheng Wu, Yafeng He, Fucheng Liu. Annular Plasma Photonic Crystals with Different Filling Ratios in Dielectric Barrier Discharge[J]. Laser & Optoelectronics Progress, 2022, 59(13): 1323002

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 59, Issue 13, 1323002 (2022)

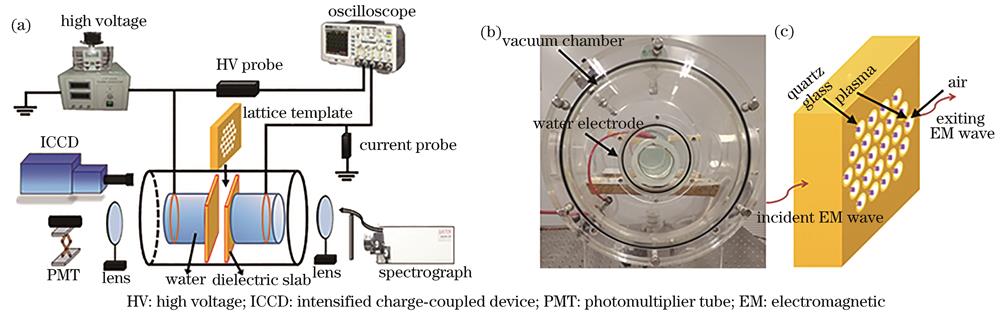

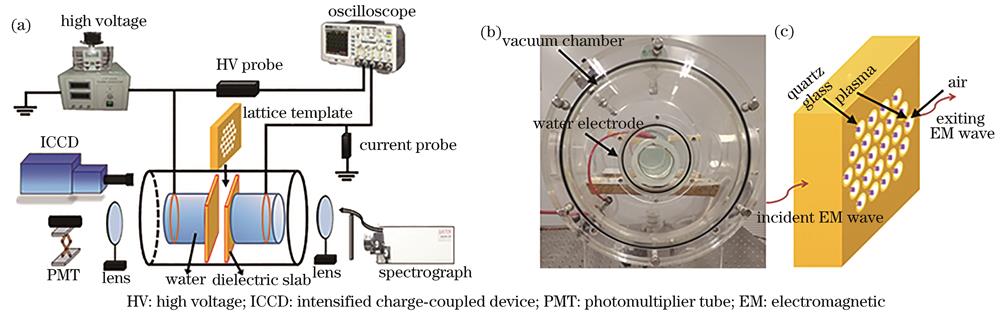

Fig. 1. Experimental setup of APPCs formation using dielectric barrier discharge system with two water electrodes. (a) Schematic diagram of experimental setup; (b) picture from realdevice; (c) schematic diagram of APPCs formation

Fig. 2. Reconfiguration of APPCs with different filling ratios by varying supply voltage and gas pressures. (a1),(b1),(c1) Snapshots of APPCs obtained in experiment; (a2),(b2),(c2) schematic diagrams of APPCs, in which circular areas in center denote plasma columns, white rings denote air and backgrounds represent quartz glass; (a3),(b3),(c3) light intensity distribution of plasmas in each annular cell. Experimental parameters: (a1)

Fig. 3. Spatio-temporally resolved measurements of discharge of APPCs with different filling ratios. (a1), (b1), (c1) Oscillogram of discharge current I, supply voltage U and light signal of one single filament A, closeups of singlecurrent pulses, denoted by strips in current waveforms, are presented in middle column; (a2), (b2), (c2) instantaneous images of discharges occurring during one single current pulse, obtained using fast camera diagnostics. Images are integrated over 30 voltage cycles to improve brightness and clarity

Fig. 4. Schematic diagram of APPCs. (a) Lattice diagram, in which

Fig. 5. Diagrams of band structures of APPCs with different filling ratios of plasmas. (a)~(d) Radii of plasma columns are 0.5, 1.0, 1.2, 1.5 mm, respectively. Structures in (a)~(c) are accordance with APPCs obtained in experiment as shown in Fig. 2(a1)~2(c1). Gray stripes and dark stripes denote unidirectional and omnidirectional band gaps, respectively

Fig. 6. Variation of the first and second band gaps with increase of plasma column radius R for APPCs and conventional triangular PPCs. APPC PBG1, APPC PBG2 denote the first and second omnidirectional band gaps for APPCs, and PPC PBG1, PPC PBG2 represent the first and second omnidirectional band gaps for conventional triangular PPCs

Set citation alerts for the article

Please enter your email address