Takanori Shimizu, Nobuaki Hatori, Makoto Okano, Masashige Ishizaka, Yutaka Urino, Tsuyoshi Yamamoto, Masahiko Mori, Takahiro Nakamura, and Yashuhiko Arakawa, "Multichannel and high-density hybrid integrated light source with a laser diode array on a silicon optical waveguide platform for interchip optical interconnection," Photonics Res. 2, A19 (2014)

Search by keywords or author

- Photonics Research

- Vol. 2, Issue 3, A19 (2014)

Fig. 1. Schematic of integrated light source in photonics-electronics convergence system.

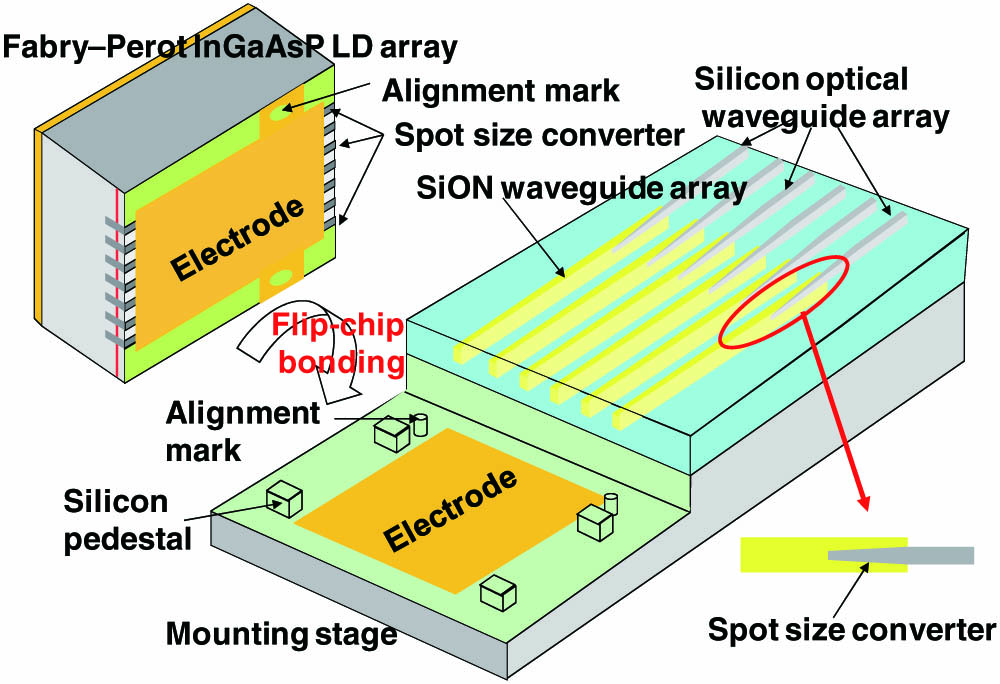

Fig. 2. Hybrid integration structure with an LD array on a silicon waveguide platform.

Fig. 3. Photograph of 13-channel LD array. Cavity length is 400 μm, and array pitch is 30 μm.

Fig. 4. Scanning electron microscope image of waveguide facet made by dry etching.

Fig. 5. (a) Schematic of LD mounting structure and (b) LD mounting image focused on alignment marks by transmission infrared light.

Fig. 6. (a) Schematic and (b) photograph of 13-channel hybrid integrated light source.

Fig. 7. Dependence of light output of 13-channel LD array on operating current at room temperature without cooling.

Fig. 8. Optical coupling tolerance between LD and SiON waveguide along horizontal and vertical directions.

Fig. 9. Relative light intensity of 13-channel LD array and waveguide output ports on integrated light source.

Fig. 10. (a) Schematic and (b) photograph of integrated light source with 52 output ports made possible by introducing waveguide splitter.

Fig. 11. Schematic showing multichip bonding technology. (a) Mounting structure and (b) illustration of diffusion of Au on surface of electrodes into AuSn bump at soldering.

Fig. 12. (a) Schematic and (b) photograph of integrated light source with 104 output ports with two LD array chips.

Fig. 13. Near-field pattern of outputs in integrated light source with 104 output ports.

Fig. 14. Histogram of relative intensity of output ports. (a) 1st–52nd channel port and (b) 53rd–104th channel port.

| ||||||||||||||||||||||||

Table 1. Requirements of Integrated Light Source for 10 Tbit / s

Set citation alerts for the article

Please enter your email address