Dapeng Wang, Wei Dou. Identification of Bolt Preload Loss Before and After Corrosion Based on Optical Frequency Domain Reflection Technique[J]. Laser & Optoelectronics Progress, 2025, 62(3): 0306004

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 62, Issue 3, 0306004 (2025)

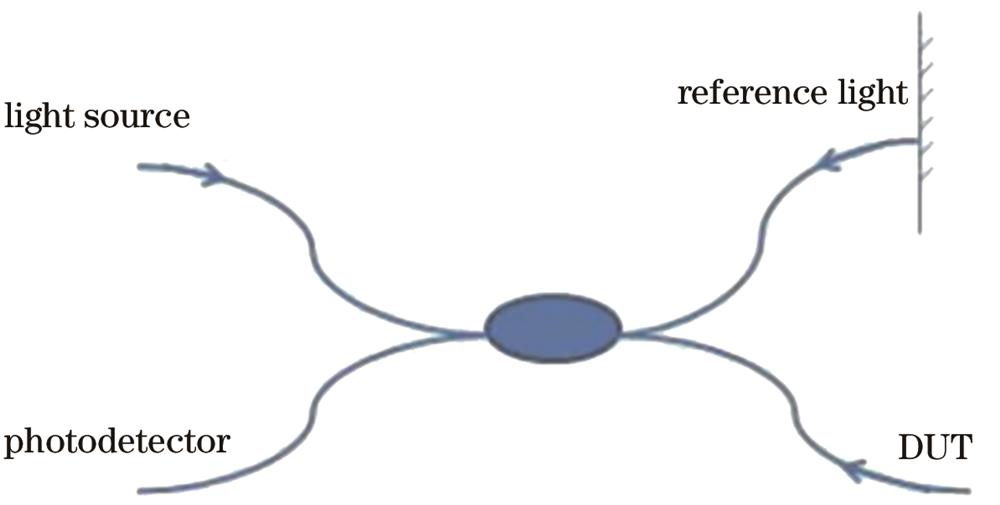

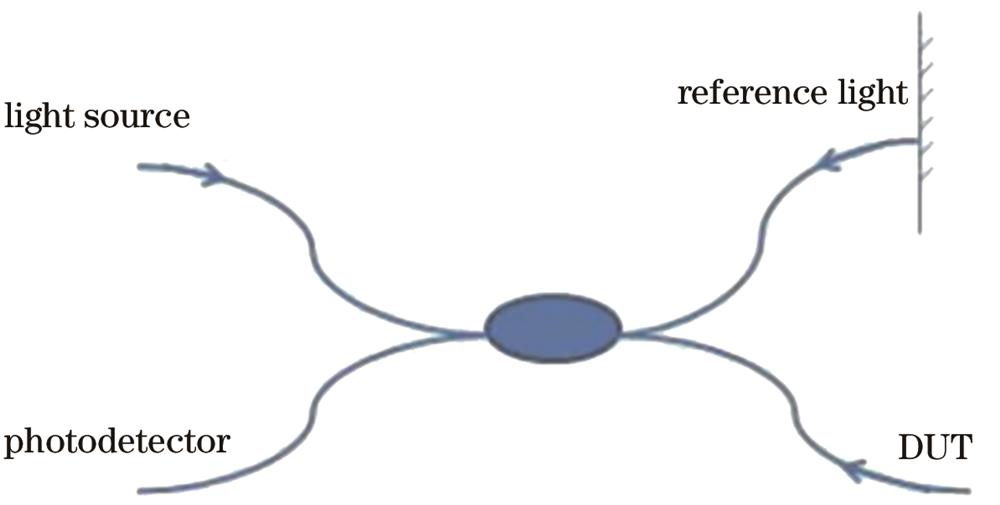

Fig. 1. OFDR basic principle diagram

Fig. 2. Optical fiber paste placement diagram for equalstrength beams

Fig. 3. Theoretical strain of equal-strength beams and optical fiber mean strain fitting curve

Fig. 4. Theoretical strain of equal-strength beams under temperature stress and optical fiber mean strain fitting curve

Fig. 5. Schematic diagrams of bolt numbering, cover dimensions, and physical fiber placement

Fig. 6. Comparison between before and after cleaning of corrosion products in group Ⅲ

Fig. 7. Schematic diagrams of distributed fiber optic paste placement after corrosion in groups Ⅱ and Ⅲ

Fig. 8. Strain distribution of unilateral 4-bolt specimens of group Ⅰ

Fig. 9. Strain distribution of group Ⅰ unilateral 9-bolt specimens

Fig. 10. Group Ⅱ unilateral 4-bolt specimen loosening bolts 1-8

Fig. 11. Group Ⅰ unilateral 9-bolt specimen loosening bolts 1-9

Fig. 12. Strain distribution of graded release preload force of No. 1 bolt of group Ⅰ

Fig. 13. Strain distribution of graded release preload force of No. 4 bolt of group Ⅰ

Fig. 14. CAD software to create 3D solid units

Fig. 15. Longitudinal 4-bolt mid-span path strain distribution in group Ⅱ

Fig. 16. Longitudinal 9-bolt mid-span path strain distribution in group Ⅰ

Fig. 17. Distribution of peak unilateral 9-peg strain in group Ⅰ

Fig. 18. Distribution of peak unilateral 9-bolt strain in group Ⅱ

Fig. 19. Distribution of peak unilateral 9-bolt strain in group Ⅲ

Fig. 20. Strain distribution of graded release preload force of No. 1 bolt of group Ⅰ

Fig. 21. Strain distribution of graded release preload force of No. 4 bolt of group Ⅰ

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Table 1. Comparison of measured and theoretical strains of distributed optical fiber

| |||||||||||||||||||||||||||

Table 2. Geometric dimensions of bolted specimens and connected steel plates

Set citation alerts for the article

Please enter your email address