Jingyu Li, Kuan Chen, Guofei Chen, Yangyan Li, Aijun Zeng, Yu Xin. Quantitative Analysis of Magnesium and Titanium Elements in Aluminum Alloy by Handheld Laser-Induced Breakdown Spectroscopy[J]. Laser & Optoelectronics Progress, 2019, 56(2): 023002

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 56, Issue 2, 023002 (2019)

Fig. 1. Schematic of optical path structure in handheld LIBS. (a) Path diagram of excitation light; (b) path diagram of signal light

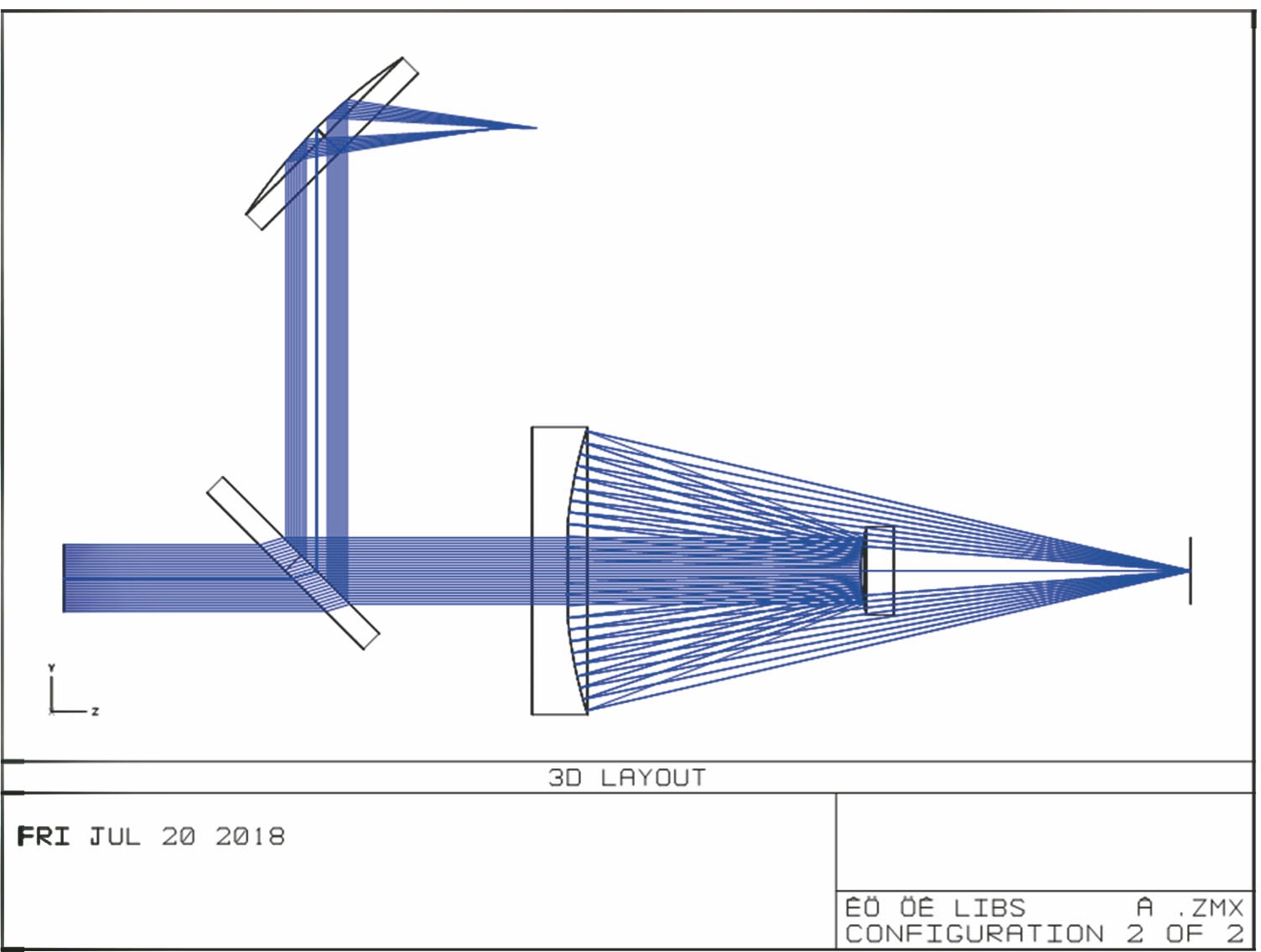

Fig. 2. Ray trace image simulated by ZEMAX

Fig. 3. Experimental setup

Fig. 4. Spectrogram. (a) Original signal spectrum; (b) processed signal spectrum

Fig. 5. Spectrum of standard sample E111

Fig. 6. Calibration curves of Mg element at 383.83 nm and 285.17 nm characteristic lines

Fig. 7. Calibration curves of Ti element at 323.38 nm and 336.12 nm characteristic lines

|

Table 1. Structural parameters of lens

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Table 2. Sample names and compositions used for drawing calibration curves

| |||||||||||||||||||||||||||||||||||||||||||

Table 3. Sample names and compositions used for verifying calibration curves

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Table 4. Verification results and relative errors of sample

| |||||||||||||||||||

Table 5. Detection limits of different spectral lines in element analysis

Set citation alerts for the article

Please enter your email address