Ziyang Wu, Zhenzhong Sun, Haoliang Wang, Chenghao Song, Changshi Lao, Luping Lin. Effect of SLM Forming Parameters on Relative-Density of 18Ni-300 Die Steel[J]. Laser & Optoelectronics Progress, 2022, 59(17): 1716001

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 59, Issue 17, 1716001 (2022)

Fig. 1. Forming sample

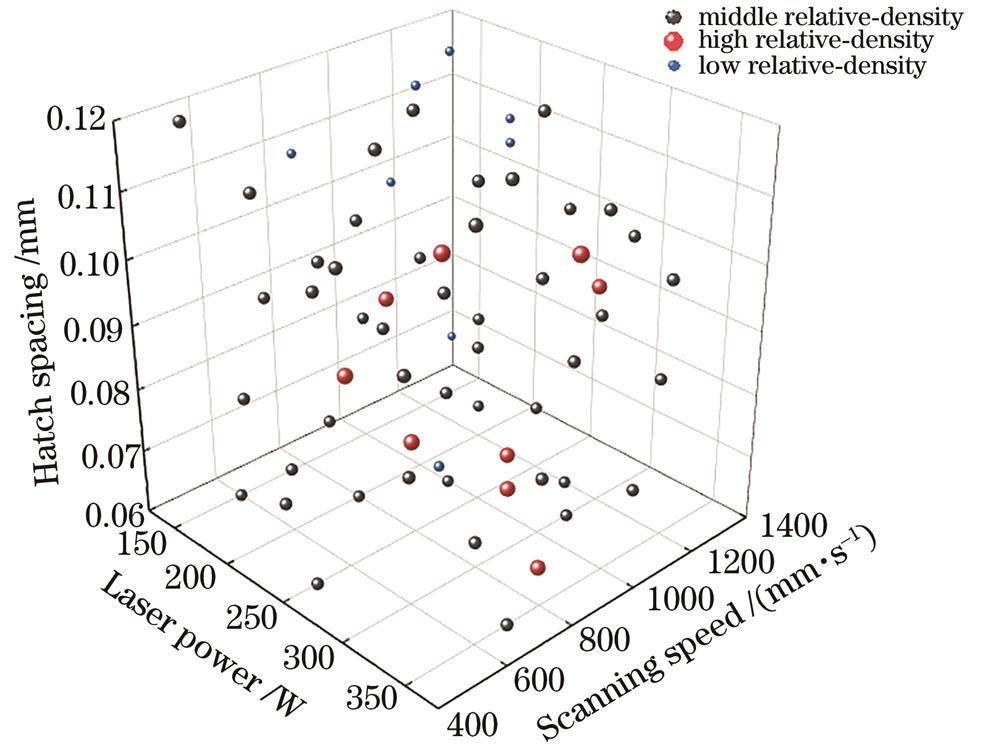

Fig. 2. Relative-density distribution of the sample in three-dimensional space

Fig. 3. Plane projection of the sample in three-dimensional space. (a) Laser power and hatch spacing; (b) scanning speed and hatch spacing

Fig. 4. Influence of various process parameters on relative-density

Fig. 5. Volume energy density and relative-density of samples with different parameter combinations

Fig. 6. Microscopic pore diagram under different energy density. (a)‒(c) Low relative-density sample; (d)‒(f) high relative-density sample

Fig. 7. Pore shapes and sizes of samples with different relative density. (a)‒(d) Low relative-density sample; (e)‒(h) high relative-density sample

Set citation alerts for the article

Please enter your email address