Guochun Liu, Hongfei Zhou, Wenfeng Yang, Dehui Lin, Guang'ao Chen. Simulation Analysis and Verification of Single Pulse Laser Paint Removal Morphology with Multi Physics Field[J]. Laser & Optoelectronics Progress, 2023, 60(15): 1514001

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 60, Issue 15, 1514001 (2023)

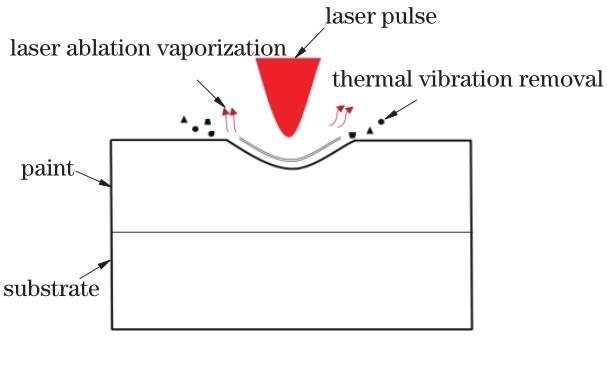

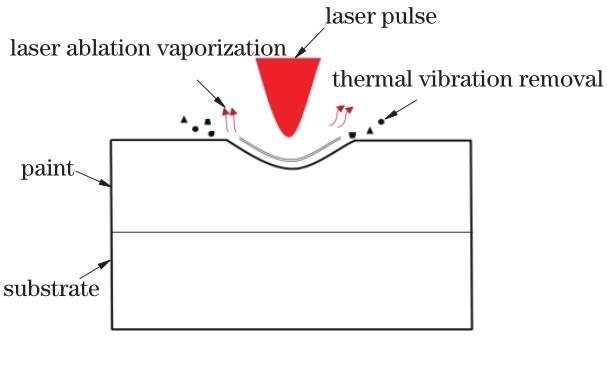

Fig. 1. Schematic diagram of pulse laser cleaning principle

Fig. 2. Infrared nanosecond pulse laser

Fig. 3. Laser confocal microscopy

Fig. 4. Experimental ablation morphology

Fig. 5. Relationship between laser energy density and ablation depth

Fig. 6. Comparison of experimental and theoretical maximum ablation width

Fig. 7. Pulse laser paint removal model

Fig. 8. Topography of paint removal for temperature criterion under different powers

Fig. 9. Topography of paint removal for thermal stress criterion under different powers

Fig. 10. Comparison of paint removal morphology obtained by two criteria under different energy densities. (a) Ablation depth; (b) ablation width

Fig. 11. Single pulse ablation morphology at laser energy density of 21.66 J/cm².(a) Experiment;(b) double criteria; (c) temperature criterion; (d) section profiles of A-A

|

Table 1. Thermal characteristic of paint and substrate

|

Table 2. Damage stress test results for paint

| |||||||||||||||||||

Table 3. Results of laser energy density

|

Table 4. Morphology parameters of paint removal under different working conditions

|

Table 5. Ablation volume at different laser powers

Set citation alerts for the article

Please enter your email address