Xiaolei DENG, Yushen CHEN, Shupeng GUO, Jiacong ZHENG, Xiaobo SHENG. Multi-source heterogeneous information acquiring test experiment and platform construction for CNC machine tool[J]. Optics and Precision Engineering, 2022, 30(12): 1440

Search by keywords or author

- Optics and Precision Engineering

- Vol. 30, Issue 12, 1440 (2022)

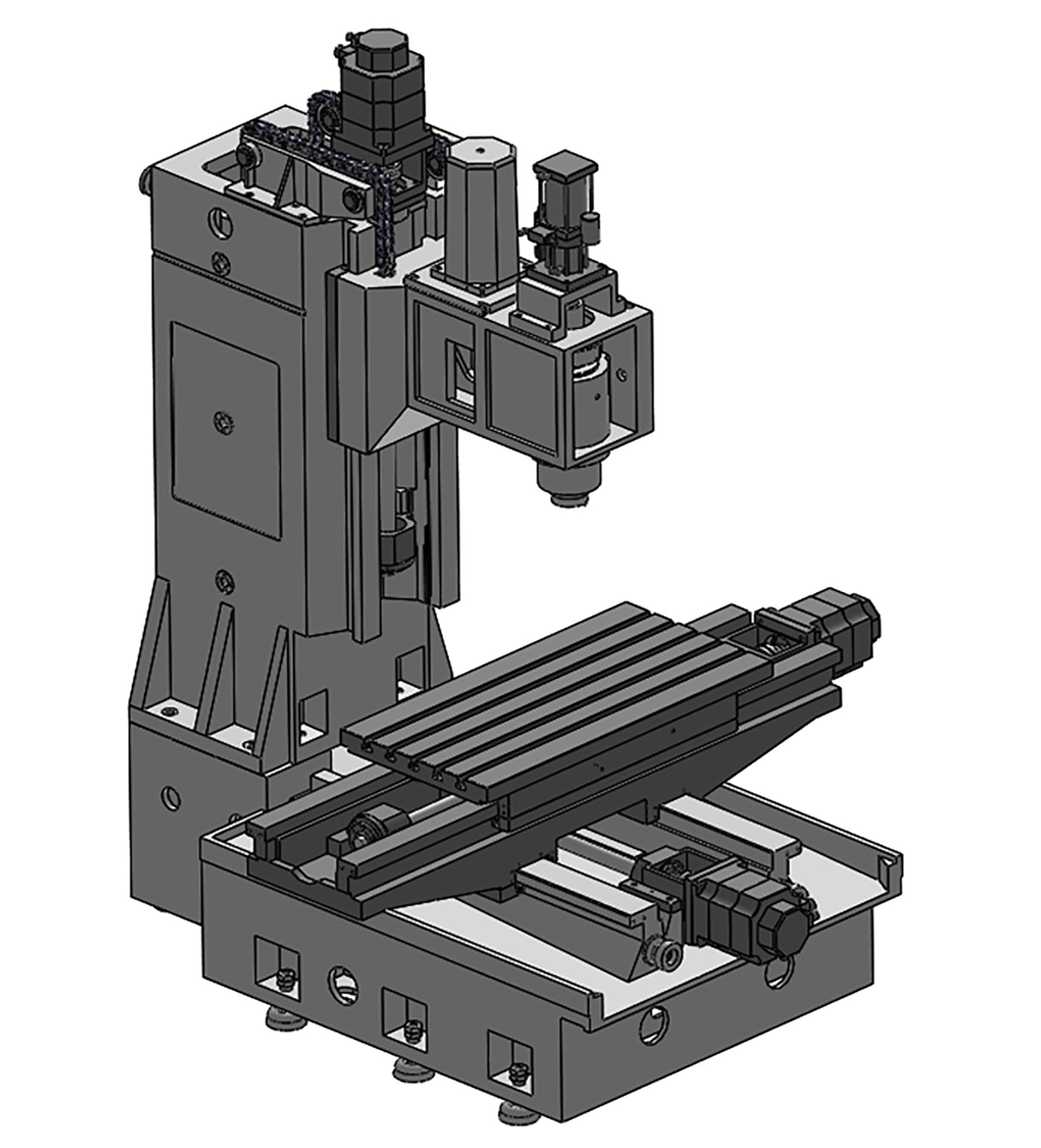

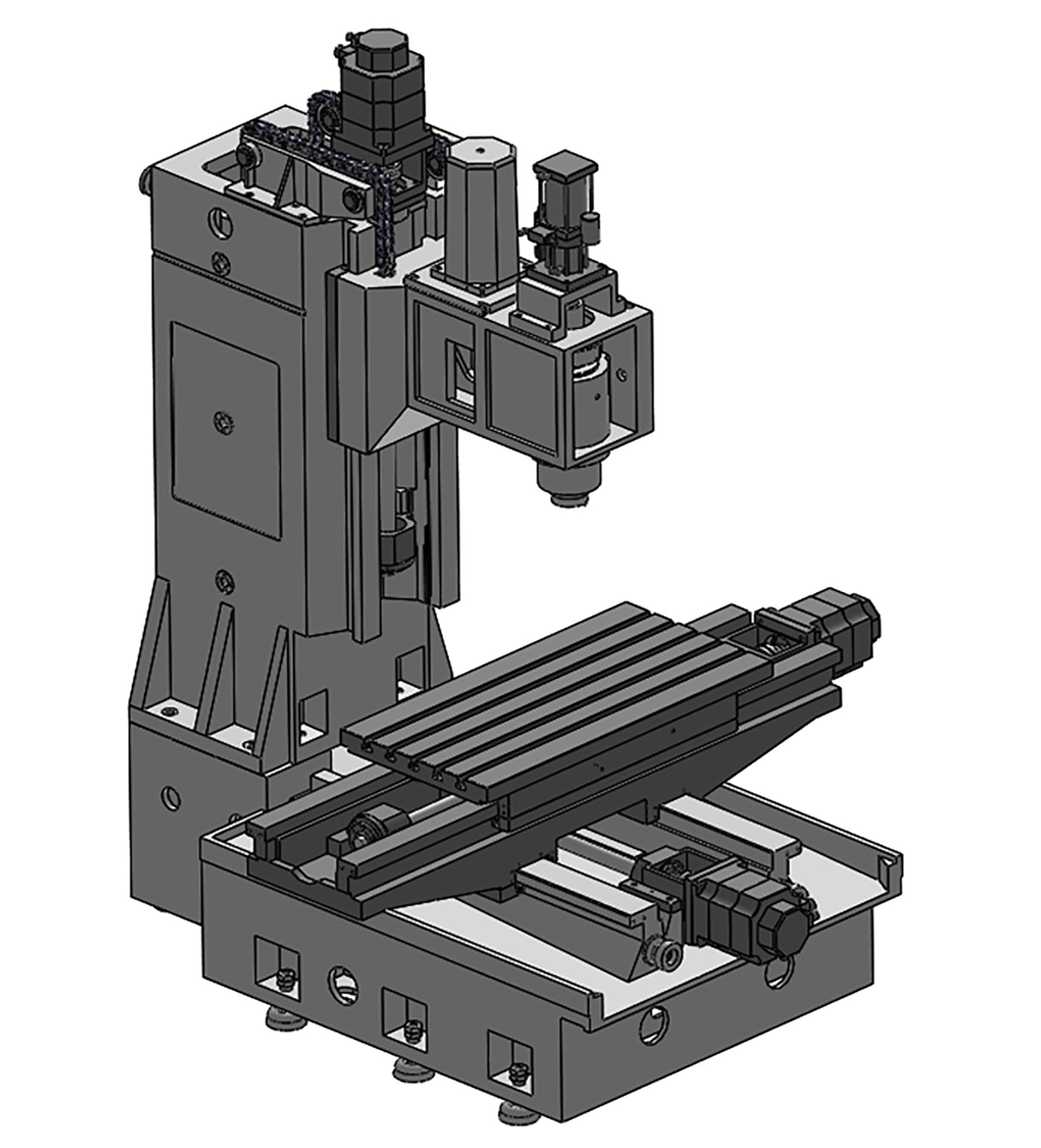

Fig. 1. Main structure 3D model of VM-850L machining center

Fig. 2. Schematic diagram of each section of spindle

Fig. 3. Cloud diagram of temperature field distribution at different rotational speed

Fig. 4. Steady-state temperature field recorded by thermal imager

Fig. 5. Cloud diagram of thermal displacement distribution at each rotational speed

Fig. 6. Test instrument on test platform

Fig. 7. Data acquisition principle

Fig. 8. Multi-source heterogeneous information collection test platform

Fig. 9. Schematic diagram of measuring point layout

Fig. 10. Temperature data of each measuring point at different speeds

Fig. 11. Signal of vibration measuring points at different speeds

Fig. 12. Signal of Z -direction displacement at different speeds

Fig. 13. Structure of RBF neural network

Fig. 14. Displacement prediction curve of RBF neural network

|

Table 1. Heat flow of each part at different speeds

| |||||||||||||||||||||||||||||

Table 2. Heat transfer coefficient of each shaft section at different speeds

|

Table 3. Total heat transfer coefficient on each face of headstock with air

|

Table 4. Location description of measuring points

|

Table 5. Comparative analysis results of Z - direction thermal deformation of spindle at different speeds

|

Table 6. Model prediction performance evaluation

Set citation alerts for the article

Please enter your email address