Jianlin Chen, Xuyue Wang. Analysis of Heat-Affected Zone and Optimization of Parameters for Laser-Cut Carbon Fiber Composites[J]. Laser & Optoelectronics Progress, 2023, 60(13): 1314002

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 60, Issue 13, 1314002 (2023)

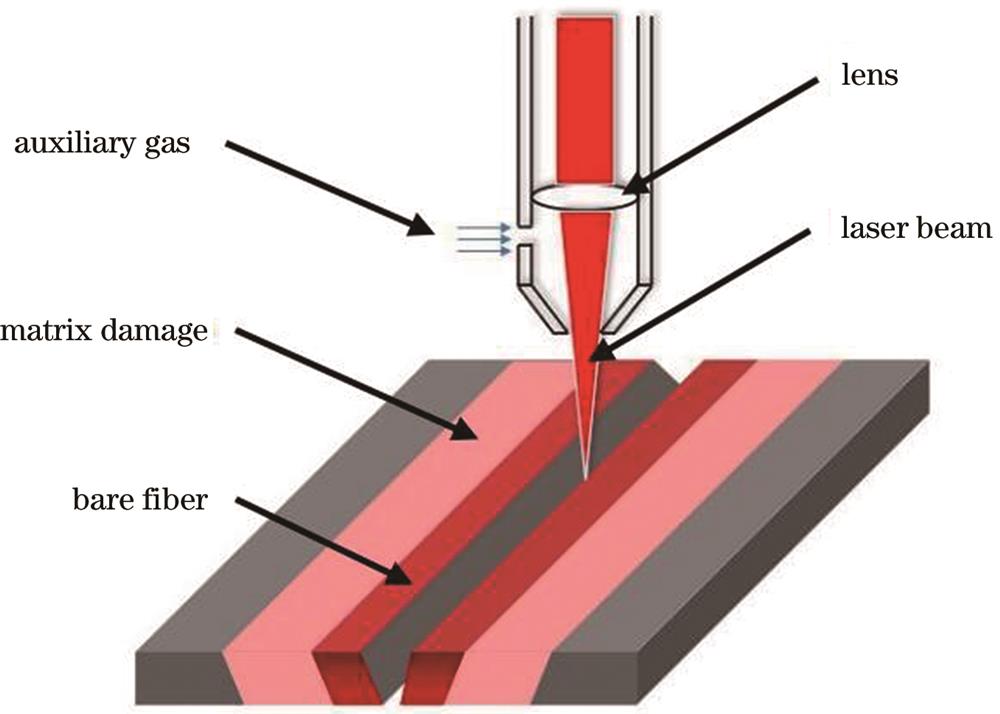

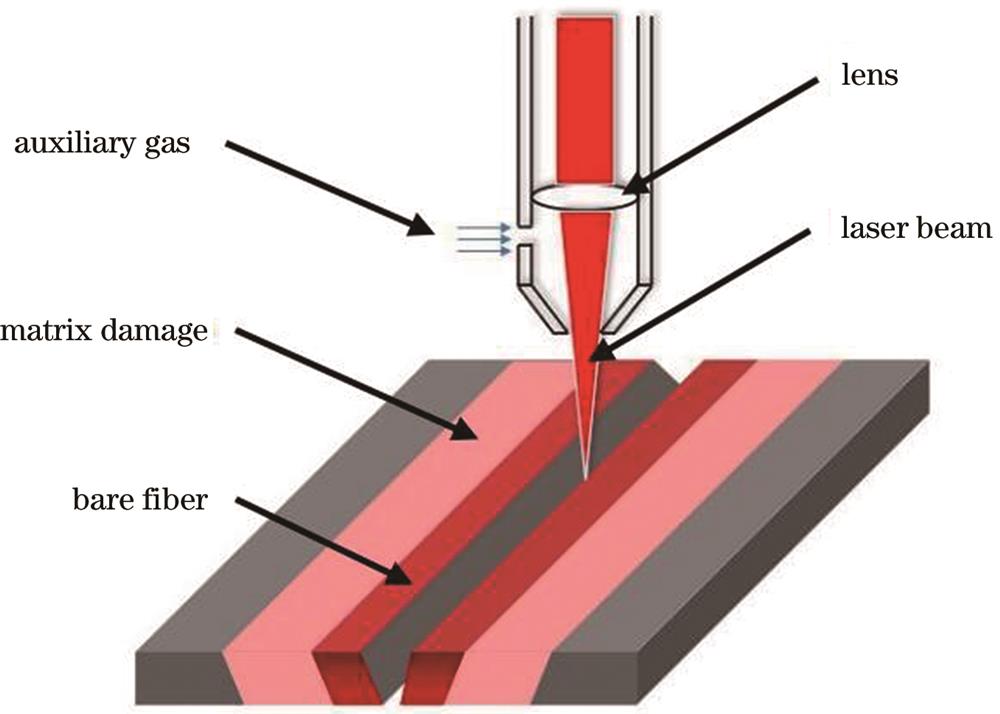

Fig. 1. Diagram of laser cutting CFRP

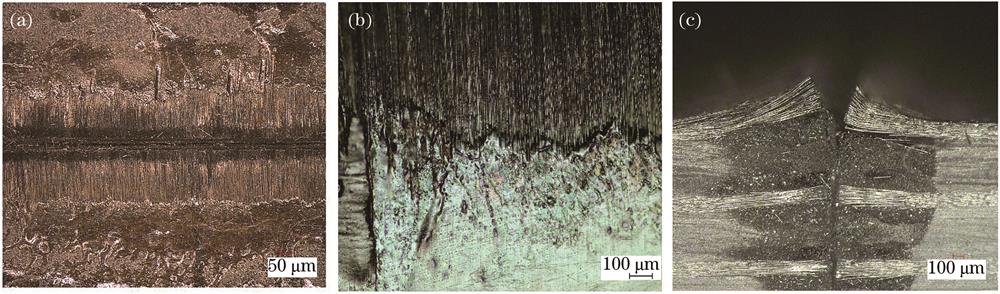

Fig. 2. Laser cutting of CFRP morphology. (a) Global morphology; (b) bare fiber; (c) material layering

Fig. 3. Morphology of HAZ on the specimen surface under different powers. (a) 150 W; (b) 450 W; (c) 750 W

Fig. 4. Morphology of HAZ on the specimen surface at different scanning speeds. (a) 1.5 m/min; (b) 2.75m /min; (c) 4 m/min

Fig. 5. Relationship between focus and artifact position

Fig. 6. Morphology of HAZ on the specimen surface at different focal positions. (a)-2 mm; (b) 0 mm; (c) 2 mm

Fig. 7. Morphology of HAZ on the specimen surface under different air pressures. (a) 0 MPa; (b) 0.4 MPa; (c) 0.8 MPa

Fig. 8. Morphology of the heat-affected zone of specimen cross section. (a) HAZmax on the top; (b) HAZmax on the inside; (c) HAZmax at the bottom

Fig. 9. Morphology of HAZ of the specimen cut section. (a) Fiber pulling out; (b) holes and cracks; (c) fibrous adhesion

Fig. 10. Model summary

Fig. 11. Pareto diagram of the standardization effect

Fig. 12. Response surface diagram. (a) Effect of power and velocity interaction on HAZ; (b) effect of power and gas pressure interaction on HAZ; (c) effect of power and focus position interaction on HAZ; (d) effect of velocity and gas pressure interaction on HAZ; (e) effect of velocity and focus position interaction on HAZ; (f) effect of gas pressure and focus position interaction on HAZ

|

Table 1. CRRP material parameters

|

Table 2. Box-Behnken test factor levels

|

Table 3. Box-Behnken test table

|

Table 4. Variance analysis of heat-affected zone width

|

Table 5. Comparison of test and fitting values for the width of the heat-affected zone

Set citation alerts for the article

Please enter your email address