[1] Cui J W, Li L, Tan J B. Optical fiber probe based on spherical coupling of light energy for inner-dimension measurement of microstructures with high aspect ratios[J]. Optics Letters, 36, 4689-4691(2011).

[2] Liu J, Pan X D, Wang G L et al. Design and accuracy analysis of pneumatic gauging for form error of spool valve inner hole[J]. Flow Measurement and Instrumentation, 23, 26-32(2012).

[3] Yu B H, Hu X P, Ye H X. Research on in process pneumatic measurement system for inner hole honing[J]. Transactions of the Chinese Society for Agricultural Machinery, 39, 202-206(2008).

[4] Zeleny J, Janda M. Automatic on-machine measurement of complex parts[J]. MM Science Journal, 2009, 93-96(2009).

[5] Fan Y Y, Zhao B. Combined non-contact coordinate measurement system and calibration method[J]. Optics & Laser Technology, 70, 100-105(2015).

[6] Shi Y Q, Sun C K, Wang P et al. High-speed measurement algorithm for the position of holes in a large plane[J]. Optics and Lasers in Engineering, 50, 1828-1835(2012).

[7] Tong Q B, Jiao C Q, Huang H et al. An automatic measuring method and system using laser triangulation scanning for the parameters of a screw thread[J]. Measurement Science and Technology, 25, 035202(2014).

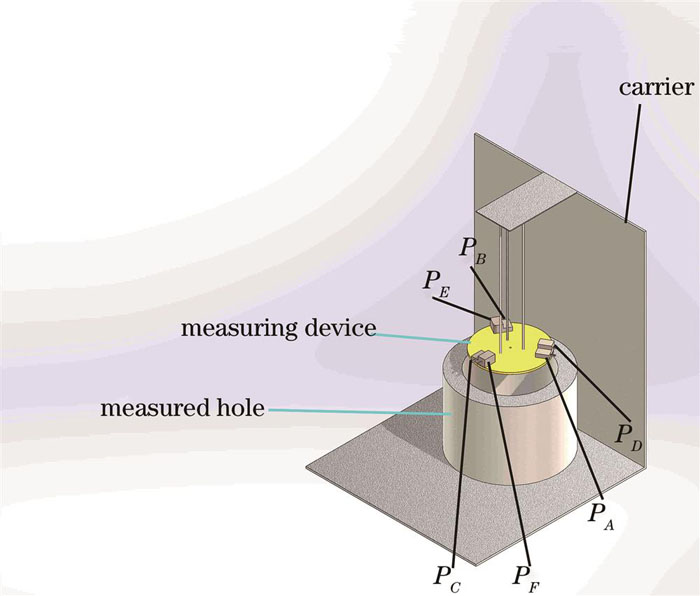

[8] Li X Q, Wang Z, Fu L H. A high-speed in situ measuring method for inner dimension inspection[J]. IEEE Transactions on Instrumentation and Measurement, 66, 104-112(2017).

[9] Zhao Z P, Yu H Y. Measurement system of diameter and coaxiality for long- span holes[J]. Industrial Instrumentation & Automation(2013).

[10] Wakayama T, Yoshizawa T. Optical center alignment technique based on inner profile measurement method[J]. Proceedings of SPIE, 9110, 91100I(2014).

[11] Yang T Y, Wang Z, Wu Z G et al. Calibration of laser beam direction for inner diameter measuring device[J]. Sensors, 17, 294(2017).

[12] Makosch G, Solf B. Surface profiling by electro-optical phase measurements[J]. Proceedings of SPIE, 0316, 42-55(1982).

[13] Chai N, Yin Z Q, Yao J H. High accuracy profile measurement with a new virtual multi-probe scanning system[J]. IEEE Access, 8, 158727-158734(2020).

[14] Tanaka H, Tozawa K, Sato H et al. Application of a new straightness measurement method to large machine tool[J]. CIRP Annals, 30, 455-459(1981).

[15] Tozawa K, Sato H, O-Hori M. A new method for the measurement of the straightness of machine tools and machined work[J]. Journal of Mechanical Design, 104, 587-592(1982).

[16] Omar B A, Holloway A J, Emmony D C. Differential phase quadrature surface profiling interferometer[J]. Applied Optics, 29, 4715-4719(1990).

[17] Gao W, Kiyono S. High accuracy profile measurement of a machined surface by the combined method[J]. Measurement, 19, 55-64(1996).

[18] Kiyono S, Gao W. Profile measurement of machined surface with a new differential method[J]. Precision Engineering, 16, 212-218(1994).

[19] Shortis M R, Fraser C S. State of the art of 3D measurement systems for industrial and engineering applications[C], 19-25(1998).

[20] Gao W, Yokoyama J, Kojima H et al. Precision measurement of cylinder straightness using a scanning multi-probe system[J]. Precision Engineering, 26, 279-288(2002).