Zhihui Luo, Xiaolong Wang, Yonghui Liang, Xinjia Yu, Jianglou Huang. Migration Monitoring Method for Ancient Building Based on Ultra-Weak Fiber Bragg Grating[J]. Laser & Optoelectronics Progress, 2025, 62(3): 0306005

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 62, Issue 3, 0306005 (2025)

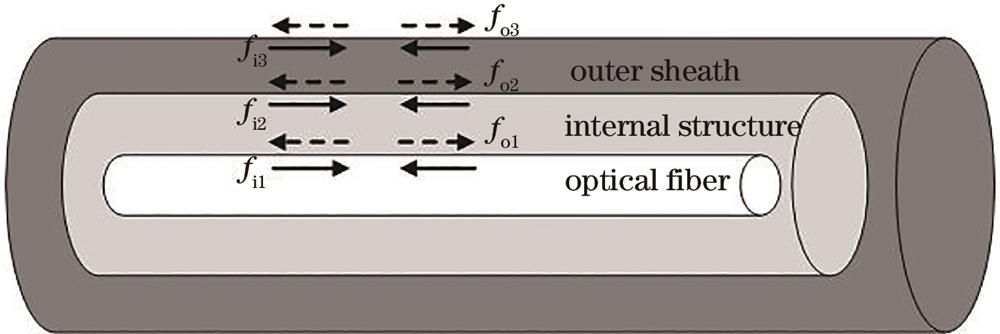

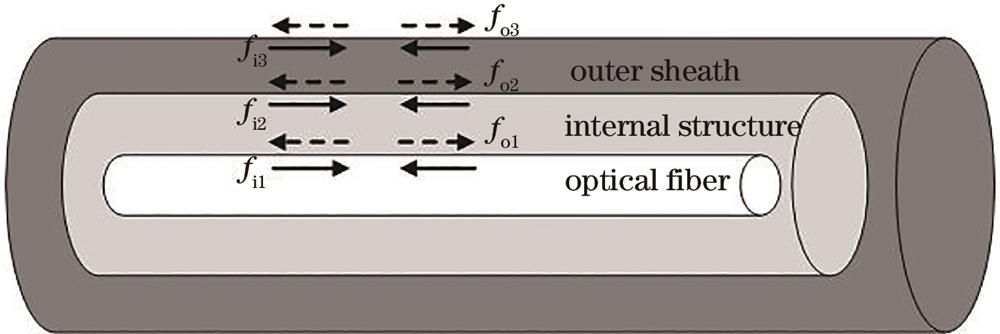

Fig. 1. Optical cable strain transfer model

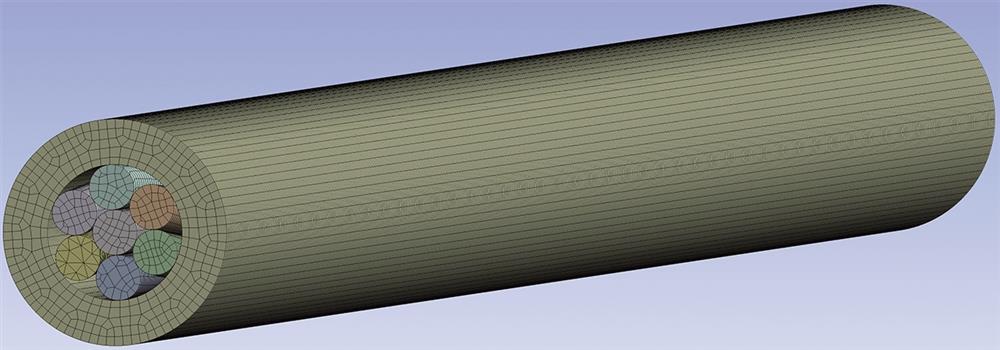

Fig. 2. Simulated structural meshing

Fig. 3. Path strain at different locations. (a) Central strain; (b) outer strain

Fig. 4. Schematic diagram of strain-curvature relationship

Fig. 5. Recursive principle of corner cutting

Fig. 6. Structure of steel strand UW-FBG strain optical cable

Fig. 7. Strain calibration curve of UW-FBG. (a) Wavelength of 1554 nm; (b) wavelength of 1542 nm; (c) wavelength of 1530 nm

Fig. 8. Temperature calibration curve of UW-FBG

Fig. 9. Layout diagram of sensor cable

Fig. 10. Migration process monitoring system

Fig. 11. Strain monitoring curves of pallet beam after concrete pouring. (a) Variation in strain in concrete curing process; (b) wavelength change after concrete complete curing

Fig. 12. Strain distribution before, during and after translation of pallet beam

Fig. 13. Nonuniform settlement of pellet beam during moving process

Fig. 14. Nonuniform settlement of pallet beam after moving

|

Table 1. Structural parameters of each layer

|

Table 2. Average strains at different locations under different pulling forces

Set citation alerts for the article

Please enter your email address