Qian Yang, Yong Hu, Yutian Ding, Jiayu Xu, Xiaokang Yang, Dong Wu. Properties and Formability of IN738 Alloy Powder for Selective Laser Melting[J]. Laser & Optoelectronics Progress, 2019, 56(10): 101402

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 56, Issue 10, 101402 (2019)

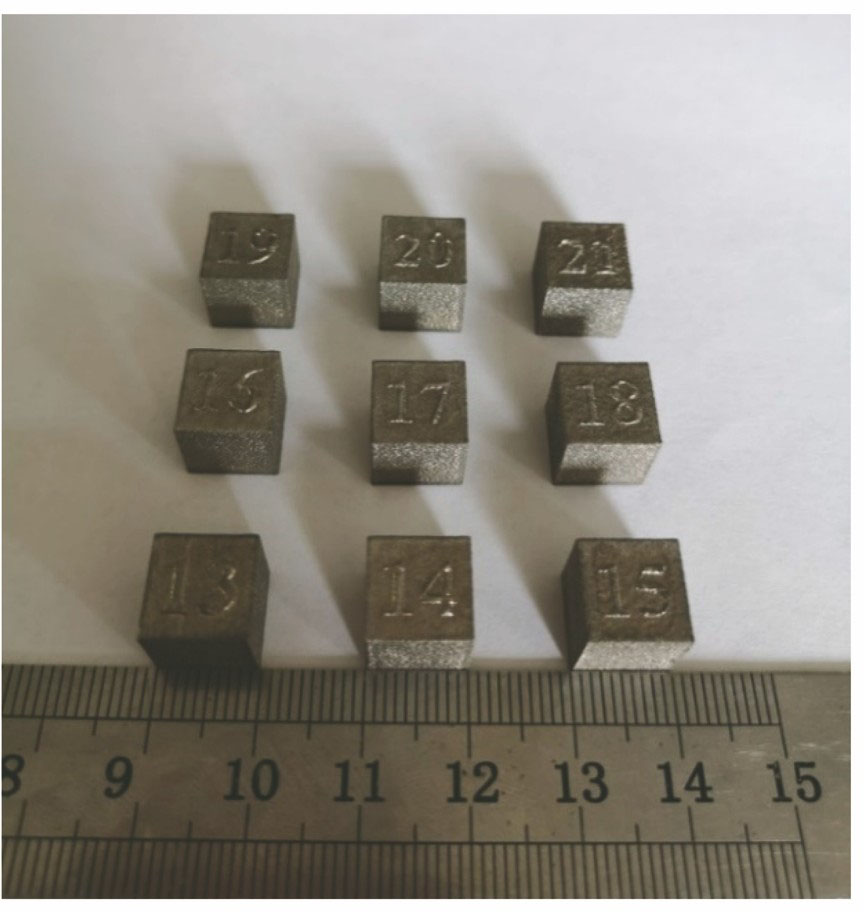

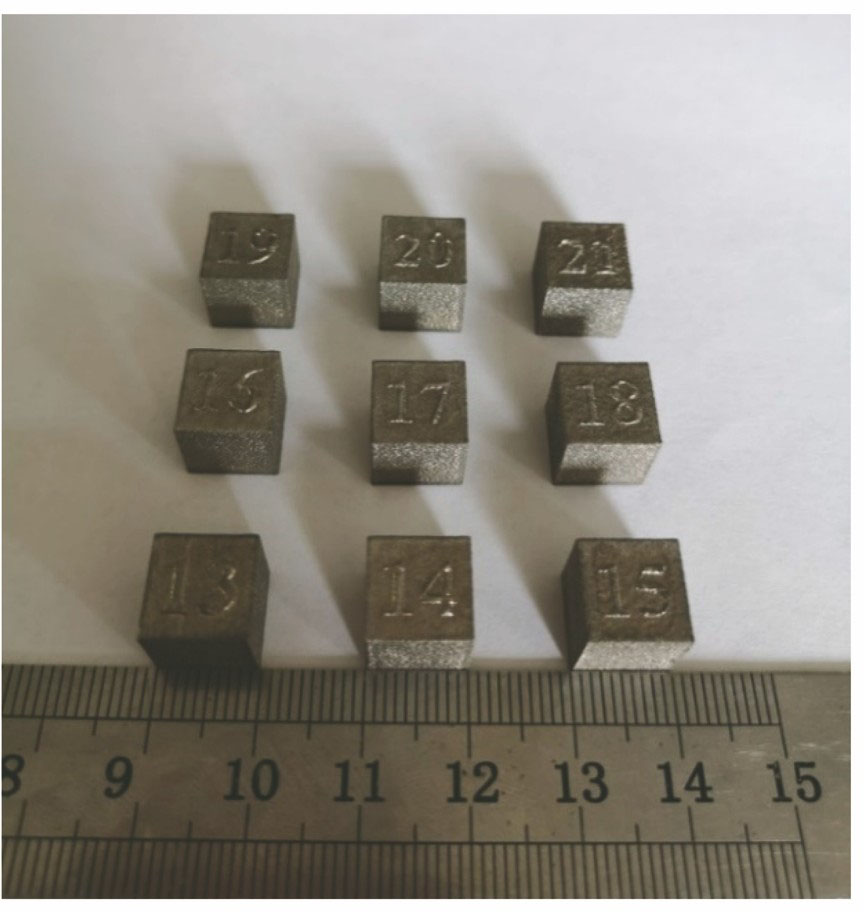

Fig. 1. IN738 cubic samples formed by SLM

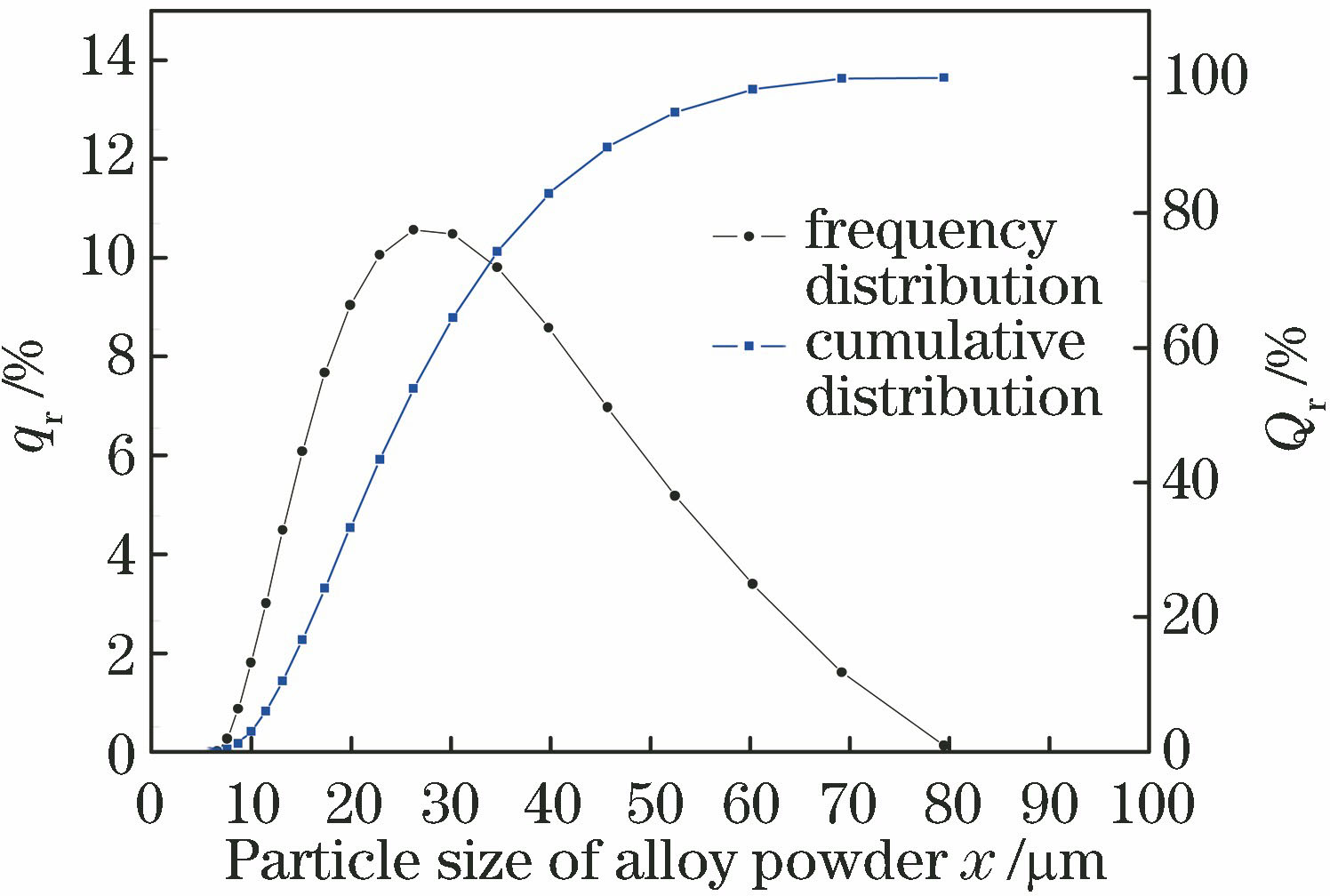

Fig. 2. Particle size distribution of IN738 alloy powder

Fig. 3. SEM morphologies of different forms of IN738 alloy powders from same batch. (a) Overall morphology of IN738 alloy powder; (b) rod-shaped powder particles; (c) coated adhesion particles; (d) satellite sphere particles

Fig. 4. Surface morphology and internal organization of IN738 alloy powder. (a) Alloy powder particle size is 72.23 μm; (b) alloy powder particle size is 33.14 μm; (c) alloy powder particle size is 14.35 μm; (d) alloy powder particle size is 6.72 μm; (e)(f) different forms of hollow alloy powders

Fig. 5. Schematic of equivalent processing

Fig. 6. Surface morphology and internal organization of IN738 printed component. (a) Splash particles scattered on part surface; (b) splash particles embedded inside part; (c) morphology of molten pool; (d) internal organization of molten pool

|

Table 1. Chemical composition of IN738 alloy powder (mass fraction, %)

|

Table 2. Physical property test results of IN738 alloy powder

Set citation alerts for the article

Please enter your email address