Yupeng Cui, Jue Gong, Mingzhen Liu. Regulation of SnO2 Electron Transport Layers for Perovskite Solar Cells[J]. Laser & Optoelectronics Progress, 2024, 61(5): 0516002

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 61, Issue 5, 0516002 (2024)

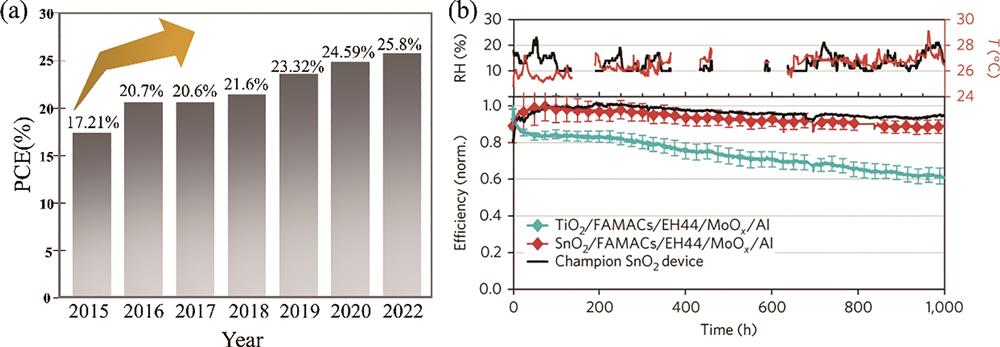

![PCE development and stability comparison of n-i-p structured single-junction PSCs. (a) Evolution of record PCE of PSCs with SnO2 ETL[10,18-23]; (b) normalized average efficiency for devices with the structure ETL/FAMACs/EH44/MoOx/Al where ETL is either TiO2 or SnO2[24]](/richHtml/lop/2024/61/5/0516002/img_01.jpg)

Fig. 1. PCE development and stability comparison of n-i-p structured single-junction PSCs. (a) Evolution of record PCE of PSCs with SnO2 ETL[10,18-23]; (b) normalized average efficiency for devices with the structure ETL/FAMACs/EH44/MoOx/Al where ETL is either TiO2 or SnO2[24]

![Stability comparison of perovskite films deposited on SnO2 and/or TiO2 being the ETL[28]. (a) Cross-sectional SEM images of perovskite films deposited on TiO2 ETL and SnO2 ETL before and after light soaking[28]; (b) photoluminescence and time-resolved photoluminescence decays of perovskite films on TiO2 ETL and SnO2 ETL before and after light soaking[28]; (c) XRD patterns (left panel) before and after 50 hours light soaking, UV-vis absorbance spectra (right panel) before and after 500 hours light soaking of perovskite films fabricated on TiO2, SnO2 and TiO2/SnO2 composite ETL[28]](/richHtml/lop/2024/61/5/0516002/img_02.jpg)

Fig. 2. Stability comparison of perovskite films deposited on SnO2 and/or TiO2 being the ETL[28]. (a) Cross-sectional SEM images of perovskite films deposited on TiO2 ETL and SnO2 ETL before and after light soaking[28]; (b) photoluminescence and time-resolved photoluminescence decays of perovskite films on TiO2 ETL and SnO2 ETL before and after light soaking[28]; (c) XRD patterns (left panel) before and after 50 hours light soaking, UV-vis absorbance spectra (right panel) before and after 500 hours light soaking of perovskite films fabricated on TiO2, SnO2 and TiO2/SnO2 composite ETL[28]

Fig. 4. Schematic illustration of various defects present at the surface and in the bulk of SnO2 ETL (upper left is the crystal structure of SnO2)[64]

Fig. 5. Several methods of passivation of SnO2/perovskite interface by improved processing. (a) Schematic diagram of UV surface treatment[80]; (b) UV-vis spectra of glass/ITO/SnO2/perovskite thin films before and after UV treatment for 500 hours[73]; (c) UV-vis spectra of glass/perovskite films before and after UV treatment of 500 h and storage in glovebox without UV for 500 h[73]; (d) schematic illustration of the modified two-step sequential deposition method for preparing perovskite films[82]; (e) energy level of the device[82]

Fig. 6. Preparation strategies of large area PSCs based on SnO2 ETL. (a) Schematic of slot-die coating of SnO2 films[83]; (b) structure of the 6 sections series connected large-area flexible PSCMs[83]; (c) AFM images of the SnO2 films without hot-air assistance and with hot-air blowing[83]; (d) schematic illustration of PSCM architecture and SnO2 films fabricated by CBD[84]; (e) light stability of 5 cm×5 cm PSCs based on pristine SnO2 and SnO2/K ETL with encapsulation (inset is photographs of 5 cm×5 cm and 10 cm×10 cm PSCs)[84]

Fig. 7. Schematic diagram of chemisorbed SAM on substrates[91]

Fig. 8. Stability testing results of perovskite films and devices prepared on SnO2 and Zw-SnO2[77]

Fig. 9. Effects of interfacial residual stresses on the device stability of PSCs. (a) Residual stresses of perovskite films prepared on SnO2 with and without KPF6 modification[108]; (b) humidity, thermal and optical stability of SnO2 unpackaged devices modified with KPF6[108]; (c) schematic diagram of NH4F modification mechanism on ETL/perovskite interface[62]

Fig. 10. Effects of additive doping in SnO2 on the device stability of PSCs. (a) PCE evolution of the unencapsulated devices storing in N2-filled glovebox[65];(b) GIXRD patterns that present the residual stress and microstrain of perovskite films with and without HCOONH4 dopant[39];(c) UV stability of the devices based on the SnO2 ETL with and without CNDs in ambient atmosphere (20 °C, 20%‒30% humidity) [119]

Fig. 11. Comparison of the stability of PSCs based on single and double ETL. (a) Energy level of PSCs with double ETL[119]; (b) air stability of unencapsulated PSCs[127]; (c) air-thermal-stability of unencapsulated PSCs[127]; (d) energy level of PSCs based on In2O3/SnO2 double ETL[130]; (e) long-term stability without encapsulation under 1 sun continuous light illumination[130]; (f) moisture stability without encapsulation under RH of 75%[130]; (g) long-term stability of N-doped bilayer ETL devices with different mass concentrations[131]; (h) stability of perovskite devices under continuous light illumination (AM 1.5 G) at room temperature[131]

|

Table 1. Various approaches used to enhance device stability of PSCs by ETL doping

Set citation alerts for the article

Please enter your email address