[1] Hua H Y. Study on Cavity Surface Damage of Semiconductor Lasers[D](2021).

[2] Yang H, Zhang B, Hu Y. A Real-time Marking Defect Inspection Method for IC Chips[C], 12.2228808(2015).

[3] Song Y, Ning Y Q, Qin L et al. Review of High-power Semiconductor Lasers Against Cavity Surface Catastrophic Optical Damage[J]. Semiconductor Optoelectronics, 41, 618-626(2020).

[4] Liu Z, Wei Y, Chen S et al. Characterization of 1 064 nm Laser Induced Damage in ALD Optical Film[J]. Journal of Applied Optics, 32, 373-376(2011).

[5] Zheng X G, Li T, Lu P et al. Analysis of Temperature Characteristics of 980 nm Semiconductor Laser Cavity Surface[J]. China Laser, 21-24(2013).

[6] Wen S Y. Microdefect-Induced Cavity Surface Thermal Effect of Semiconductor Lasers[D](2021).

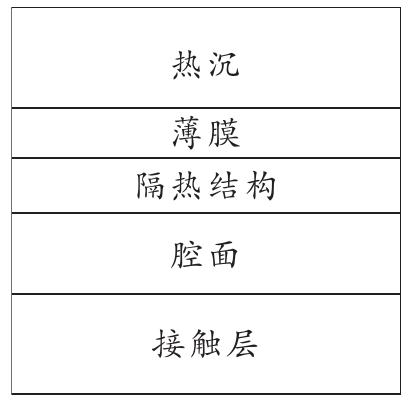

[7] Li Z J, Hu L M, Wang Y et al. Cavity Surface Coating of 808 nm Aluminum-containing Semiconductor Laser[J]. Optical Precision Engineering, 18, 1258-1263(2010).

[8] Zhang S Y, Feng S W, Zhang Y M et al. Monitoring of Early Catastrophic Optical Damage in Laser Diodes based on Facet Reflectivity Measurement[J]. Applied Physics Letters, 110, 223503(2017).

[9] Michaud J, Vecchio D P, Béchou L et al. Precise Facet Temperature Distribution of High-power Laser Diodes: Unpumped Window Effect[J]. IEEE Photonics Technology Letters, 27, 1002-1005(2015).

[10] Sun H, Ma L, Najeem A et al. Background Thermal Noise Correction Methodology for Average Infrared Radiation Temperature of Coal under Uniaxial Loading[J]. Infrared Physics & Technology, 81, 157-165(2017).

[11] Ouyang S, Liu Z, Xu Q. Surface Damage Precursors in Triple‐frequency Fused Silica[J]. Journal of Applied Optics, 32, 1257-1262(2011).

[12] Hui L, Li B, Wang X et al. Automated Defect Inspection of LED Chip Using Deep Convolutional Neural Network[J]. Journal of Intelligent Manufacturing, 30, 2525-2534(2019).

[13] Xu J M, Mao D H, Tang D M. Study on the Influence of External Wall Enclosure Structure on Natural Room Temperature[J]. Journal of Dongguan University of Technology, 27, 70-77(2020).

[14] Wang X L. Study on High-power Semiconductor Laser Cavity Mask[D](2014).

[15] Luan Q, Sui X Y, Cui T Y. Development of High-performance Ceramic Thermal Insulation Materials[J]. Modern Technical Ceramics, 32, 17-19(2011).

[16] Chen Y, Li D, Sun C C. Study on the Response Characteristics of Thermal-mechanical Coupling of Rigid Ceramic Thermal Insulation Tiles[J]. Journal of Engineering Thermophysics, 41, 3020-3029(2020).

[17] Zhao S. Digiyal Simulation and Experimental Study on Differential Temperature Rolling and Deformation Permeability of Medium and Heavy Plates[D](2015).

[18] Zhang W B. Structural Optimization of a Certain Type of Power Take-off and Analysis of Its Dynamic Characteristics[D](2015).