Zhiqin Lei, Lifang Mei, Dongbin Yan, Genyu Chen, Wei Yin, Shun Xie. Research on Properties of SiC/18Ni300 Maraging Steel Composite Material Using Selective Laser Melting[J]. Laser & Optoelectronics Progress, 2023, 60(1): 0116001

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 60, Issue 1, 0116001 (2023)

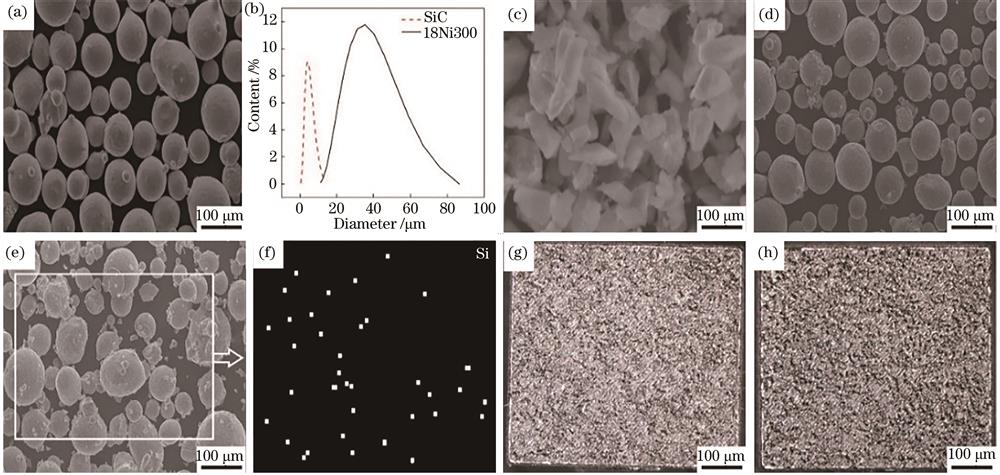

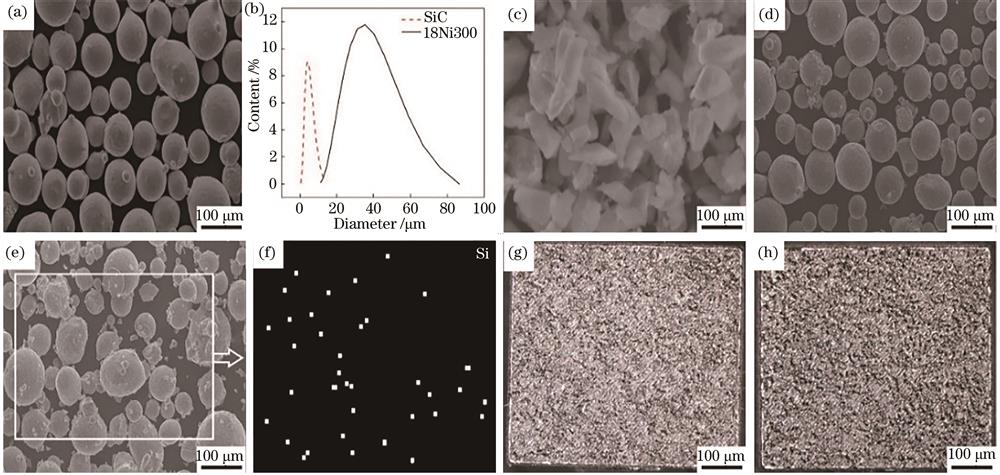

Fig. 1. Powders and formed specimen. (a) 18Ni300 powders; (b) particle size distributions of SiC and 18Ni300 powders; (c) SiC powders; (d) mixed powder with volume fraction of 0.3% SiC; (e) mixed powder with volume fraction of 1% SiC; (f) Si element; (g) sample with volume fraction of 2% SiC; (h) sample with volume fraction of 3% SiC

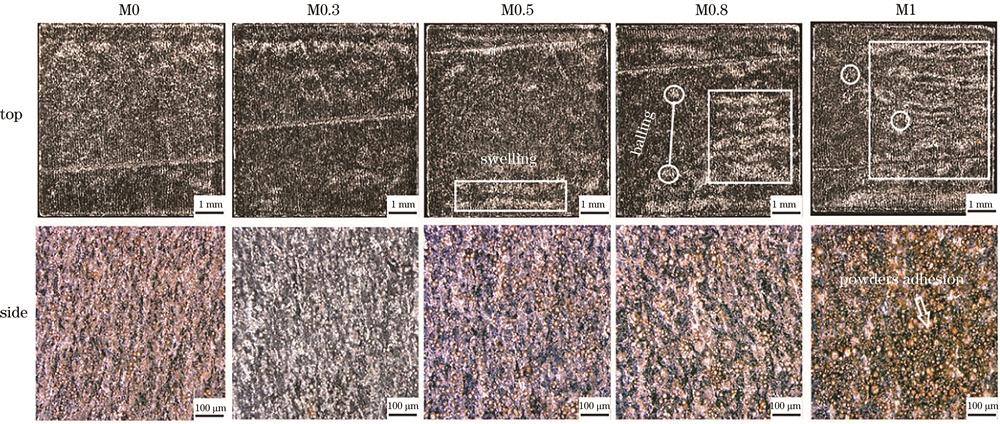

Fig. 2. Top and side morphology of the sample

Fig. 3. Formed sample and its surface roughness value

Fig. 4. Polished surface morphologies of the sample

Fig. 5. Microstructure and the EDS mapping analysis of the sample. (a) M0 sample; (b) M0.5 sample; (c) M1 sample

Fig. 6. Analysis of mechanical properties of the sample. (a) Hardness curve; (b) stress-strain curves; (c) ultimate tensile strength-elongation curves

Fig. 7. Fracture morphology of tensile specimens. (a) M0; (b) M0.3; (c) M0.5; (d) M0.8; (e) M1

Set citation alerts for the article

Please enter your email address