Yanrong Ding, Ruilin Bai, Jian Ni. Sub-Pixel Corner Location Method Based on Curvature and Gray[J]. Laser & Optoelectronics Progress, 2018, 55(3): 031501

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 55, Issue 3, 031501 (2018)

Fig. 1. Motor shaft images acquired by the test system. (a) Motor shaft image; (b) partial image; (c) enlarged view of ROI

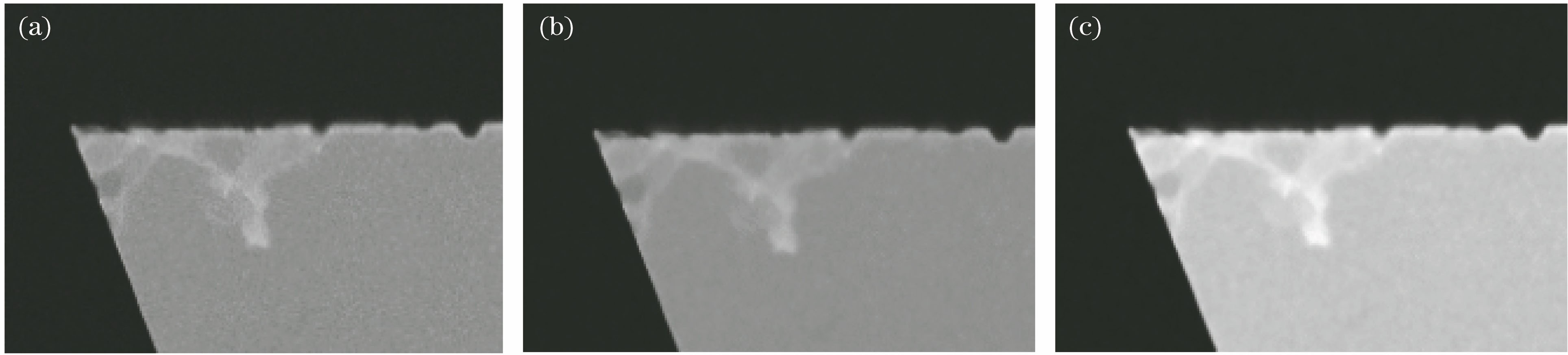

Fig. 2. Partial screenshot of image preprocessing. (a) Morphological treatment; (b) bilateral filtering; (c) Gaussian filtering

Fig. 3. Angle of curvature calculation diagram

Fig. 4. False-corner type on the workpiece surface and the gray information of its circular window. (a) False-corner type; (b) circular window gray information of false-corner 1, 3; (c) circular window gray information of false-corner 2

Fig. 5. Shaft type optical measurement system

Fig. 6. Corner and size to be detected

Fig. 7. Candidate corner screenshots

Fig. 8. Angular distribution of the corners at different scales. (a) Angle of curvature of the true corner; (b) angle of curvature of the corner 2; (c) the angle of curvature of the corner 9; (d) the angle of curvature of the corner 12

Fig. 9. Sub-pixel positioning step-by-step results screenshot. (a) Corner and endpoint connection; (b) edge extraction; (c) line point set 1; (d) line point set 2; (e) straight line fitting and intersection

Fig. 10. Corner detection results. (a) Result in Ref.[9]; (b) results in this paper

|

Table 1. Absolute deviation of the curvature angle of partial candidate corners

|

Table 3. Duplicate test results for individual artifactsmm

|

Table 4. Algorithm accuracy test resultsmm

|

Table 5. Multiple workpiece detection resultsmm

Set citation alerts for the article

Please enter your email address