Zhan Wang, Wenlei Sun, Haibo Huang, Jiangtong Yu, Jinduo Liu. Effect of Ultrasonic Vibrations on Quality of Laser Cladding Layer with Low Overlap Rate[J]. Laser & Optoelectronics Progress, 2019, 56(14): 141402

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 56, Issue 14, 141402 (2019)

Fig. 1. Schematic of overlap rate

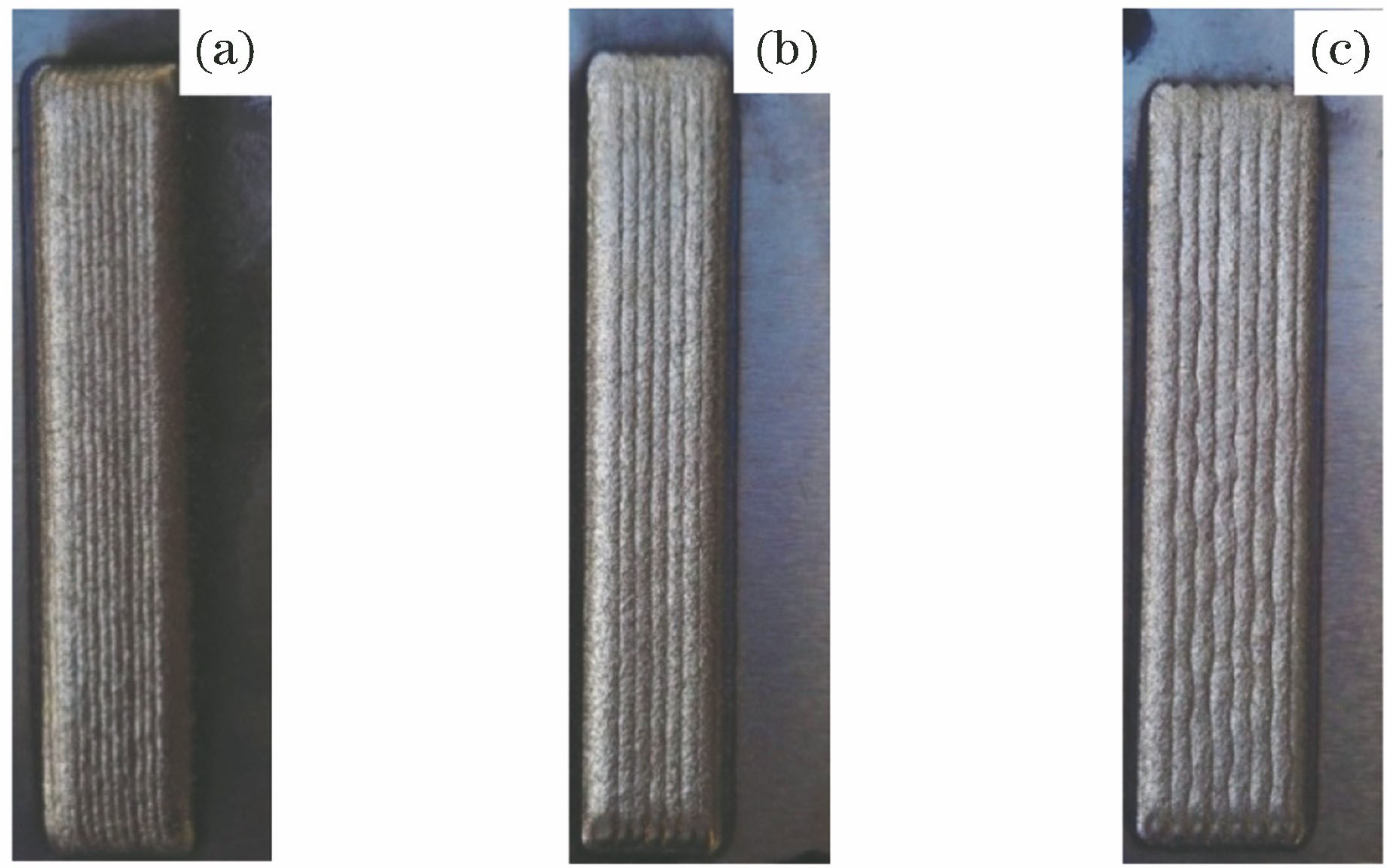

Fig. 2. Macroscopic morphology of cladding layers with different overlap rates under ultrasonic vibration. (a) 66%; (b) 50%; (c) 33%

Fig. 3. Comparison of macroscopic morphology of cladding layer at 33% overlap rate. (a) With ultrasonic vibration; (b) without ultrasonic vibration

Fig. 4. Optical micrographs of cladding layer profile with overlap rate of 33%. (a) Without ultrasonic vibration; (b) with ultrasonic vibration

Fig. 5. SEM images of cladding layer with overlap rate of 33%. (a) Without ultrasonic vibration; (b) with ultrasonic vibration

Fig. 6. Change of microhardness with overlap rate of 33%

Fig. 7. Comparison of wear resistance with overlap rate of 33%

|

Table 1. Element composition of No. 45 steel (mass fraction, %)

|

Table 2. Element composition of Ni60 self-melting alloy powder (mass fraction, %)

|

Table 3. Parameters of laser cladding process

Set citation alerts for the article

Please enter your email address