Hu Zhou, Dengdeng Shu, Chongjun Wu, Qibing Wang. Full Runout Measurement of DD Motor End Face Based on Point Cloud Drive[J]. Laser & Optoelectronics Progress, 2023, 60(12): 1215006

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 60, Issue 12, 1215006 (2023)

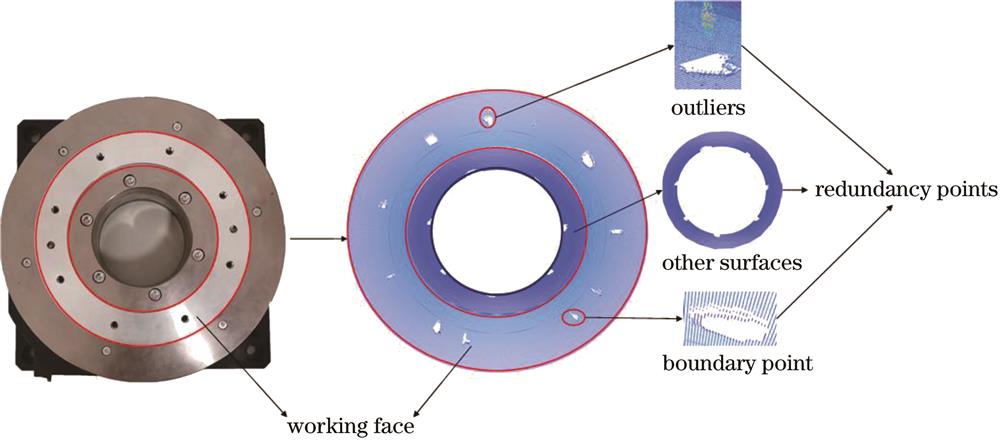

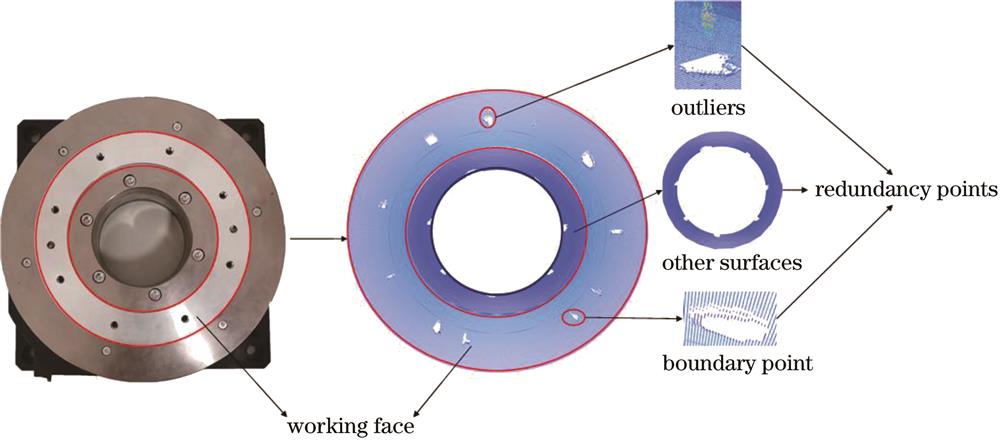

Fig. 1. Point cloud of DD motor

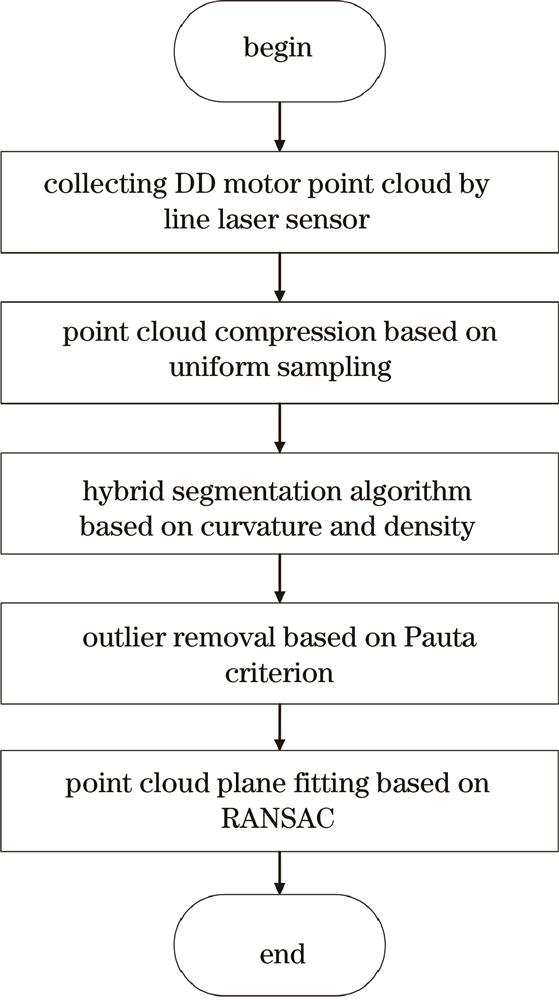

Fig. 2. Flow chart of proposed method

Fig. 3. Experimental platform and collected point cloud

Fig. 4. Schematic diagram of point cloud density

Fig. 5. Flow chart of hybrid segmentation algorithm based on curvature and density

Fig. 6. Anomaly analysis of point cloud. (a) Segmented working face point cloud; (b) point cloud line chart

Fig. 7. Verification diagrams of normal distribution of point cloud. (a) Q-Q graph of point cloud; (b) frequency histogram

Fig. 8. Point cloud compression results

Fig. 9. Results of point cloud segmentation. (a)

Fig. 10. Point cloud after outlier elimination and corresponding line chart. (a) Point cloud after outlier elimination; (b) point cloud line chart

Fig. 11. Measurement result

Fig. 12. Schematic diagram of dial indicator measurement

|

Table 1. Parameters of linear laser sensor

|

Table 2. Comparison of RANSAC fitting results under different parameters

|

Table 3. Measurement data of left end of bolt hole

|

Table 4. Measurement data of right end of bolt hole

Set citation alerts for the article

Please enter your email address