Wu Yue, Chenggong Gong, Wei Hu, Zimao Wu. Effect of Co Content and Microcracks on Laser Shock Resistance of WC Nozzle[J]. Laser & Optoelectronics Progress, 2023, 60(1): 0114010

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 60, Issue 1, 0114010 (2023)

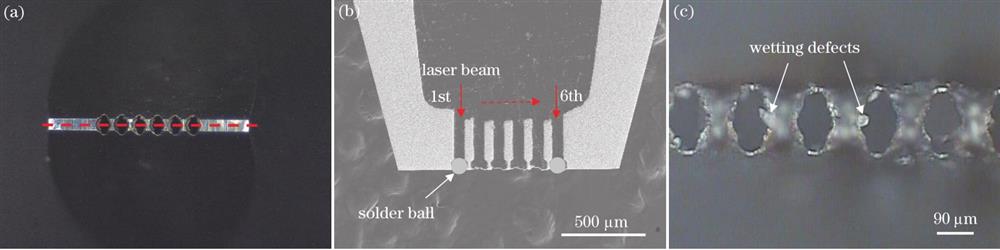

Fig. 1. Sketch of right-angle Au/SnAgCu/Au micro solder joints prepared by laser solder ball bonding

Fig. 2. WC nozzle using in LJSBB. (a) Front view image of nozzle; (b) cross section at the dash line in Fig. (a); (c) tinning defects

Fig. 3. Microstructure of WC nozzle enduring different laser shocks. (a) 2.0×105 times; (b) 3.0×105 times

Fig. 4. Microstructure of WC nozzle at 4500 MPa sintering pressure, laser shock resistance is about 1.7×105 times

Fig. 5. Microstructure of WC nozzle at 3800 MPa sintering pressure, laser shock resistance is 2.9×105 times

Fig. 6. Sketch of laser beam passed inner hole of WC nozzle. (a) Entered microcrack after multi-reflecting; (b) directly passed inner hole

| ||||||||||||||||||||||||||||||||||||||

Table 1. Elements result of marked points in Fig. 3

|

Table 2. Relationship between different factors and laser shock resistance times

Set citation alerts for the article

Please enter your email address