Li Cheng, Chao Wu, Yan Chen, Zhengjun Xiong. Removal of Liquid Crystal Polymer Flexible Copper-Clad Laminates Using Ultraviolet Laser[J]. Laser & Optoelectronics Progress, 2022, 59(17): 1714007

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 59, Issue 17, 1714007 (2022)

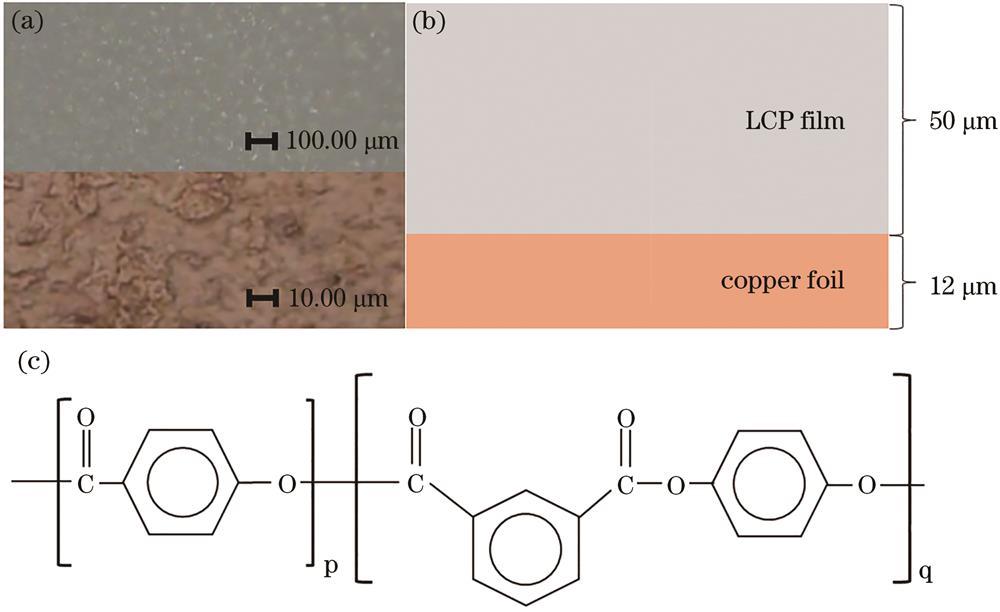

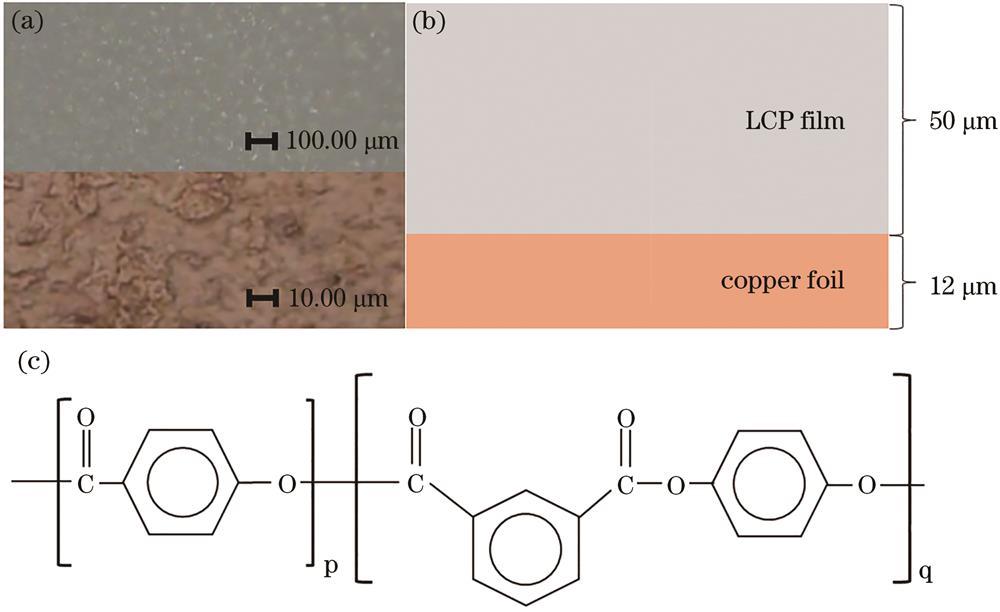

Fig. 1. Experimental material. (a) Micromorphology of LCP flexible copper-clad laminates; (b) size of LCP flexible copper-clad laminates; (c) molecular structure of PHB-PPI copolymer LCP

Fig. 2. Schematic of the experimental setup of ultraviolet processing system

Fig. 3. Experimental results. (a) Schematic of heat-affected zone; (b) HAZ measurement chart of LCP under a confocal microscope

Fig. 4. Removal depth versus average power

Fig. 5. HAZ width versus average power

Fig. 6. Experimental results. (a) Energy density distribution of a Gaussian beam; (b) effect of laser power on plasma zone

Fig. 7. Micromorphology of LCP substrate film removal obtained under different laser powers. (a) P=1.5 W; (b) P=2.7 W; (c) P=3.6 W

Fig. 8. Removal depth versus scanning speed

Fig. 9. HAZ width versus scanning speed

Fig. 10. Effect of spot overlap rate on film removal. (a) v<500 mm/s; (b) v>700 mm/s

Fig. 11. Micromorphology of the LCP substrate film removal obtained at different scanning speeds. (a) v =300 mm/s; (b) v =600 mm/s; (c) v =1000 mm/s

Fig. 12. Removal depth versus number of scanning layers

Fig. 13. HAZ width versus number of scanning layers

Fig. 14. Micromorphology of the LCP substrate film removal obtained with different number of layers. (a) Number of layers is 1; (b) number of layers is 4; (c) number of layers is 8

|

Table 1. Physicochemical properties of experimental sample

|

Table 2. Main technical parameters of laser

Set citation alerts for the article

Please enter your email address