Danyang Feng, Yicheng Xiao, Zunfeng Liu. Recent Developments in Elastocaloric Cooling[J]. Laser & Optoelectronics Progress, 2023, 60(13): 1316014

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 60, Issue 13, 1316014 (2023)

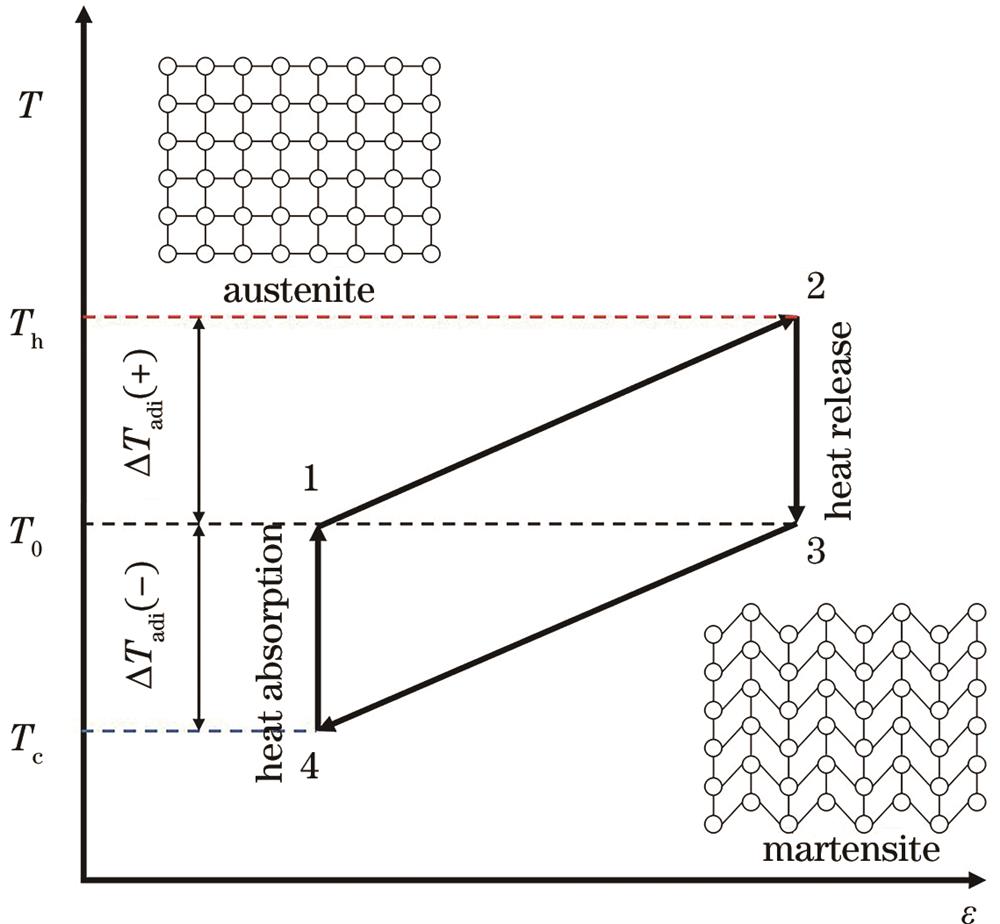

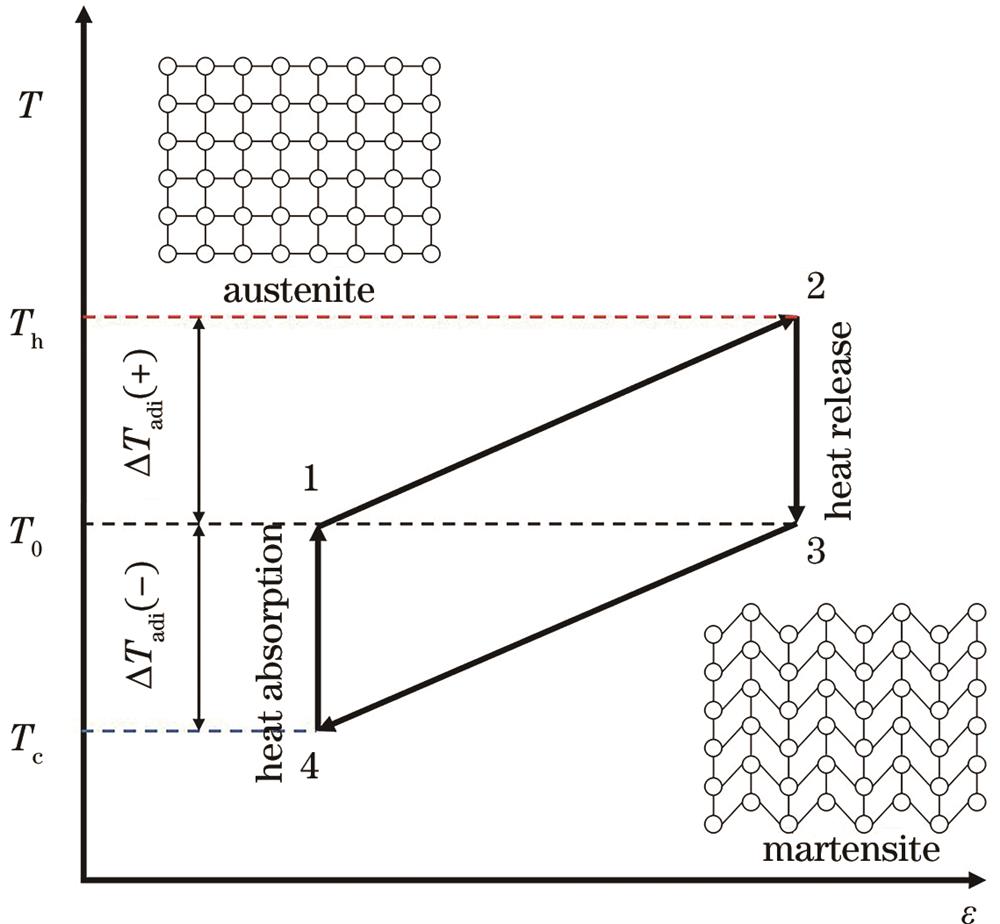

Fig. 1. Schematic diagram of the elastocaloric effect of a shape memory alloy

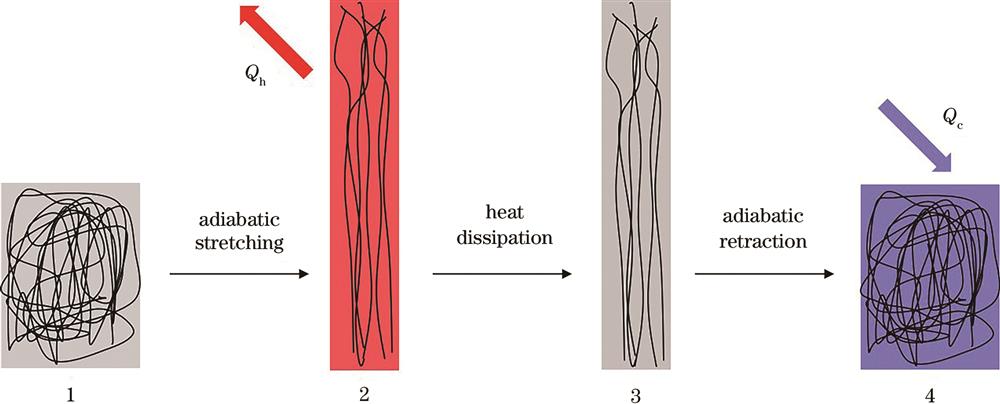

Fig. 2. Schematic of the elastocaloric effect of the elastic polymer

Fig. 3. The temperature change of NiTi wires during loading and unloading

Fig. 4. Temperature change of the sample as a function of time upon fast unloading,the inset shows the temperature changes of Cu alloy during loading and unloading processes

Fig. 5. Compressive stress and the corresponding temperature change of the sample as a function of time[60]

Fig. 6. Stress-induced changes of entropy as a function of temperature for selected values of the applied force

Fig. 7. Temperature and stress of a polymer elastomer during deformation

Fig. 8. Elastocaloric cooling device based on shape memory alloys that transfer heat through fluids

Fig. 9. Elastocaloric cooling device based on elastic polymer

|

Table 1. Parameters of shape memory alloys

Set citation alerts for the article

Please enter your email address