Jinghong Wu, Hao Liu, Peng Yang, Na Jiang. Identification and Monitoring of Concrete Cracks Based on Optical Frequency Domain Reflectometry Technique[J]. Laser & Optoelectronics Progress, 2019, 56(24): 241201

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 56, Issue 24, 241201 (2019)

Fig. 1. Working principle of OFDR

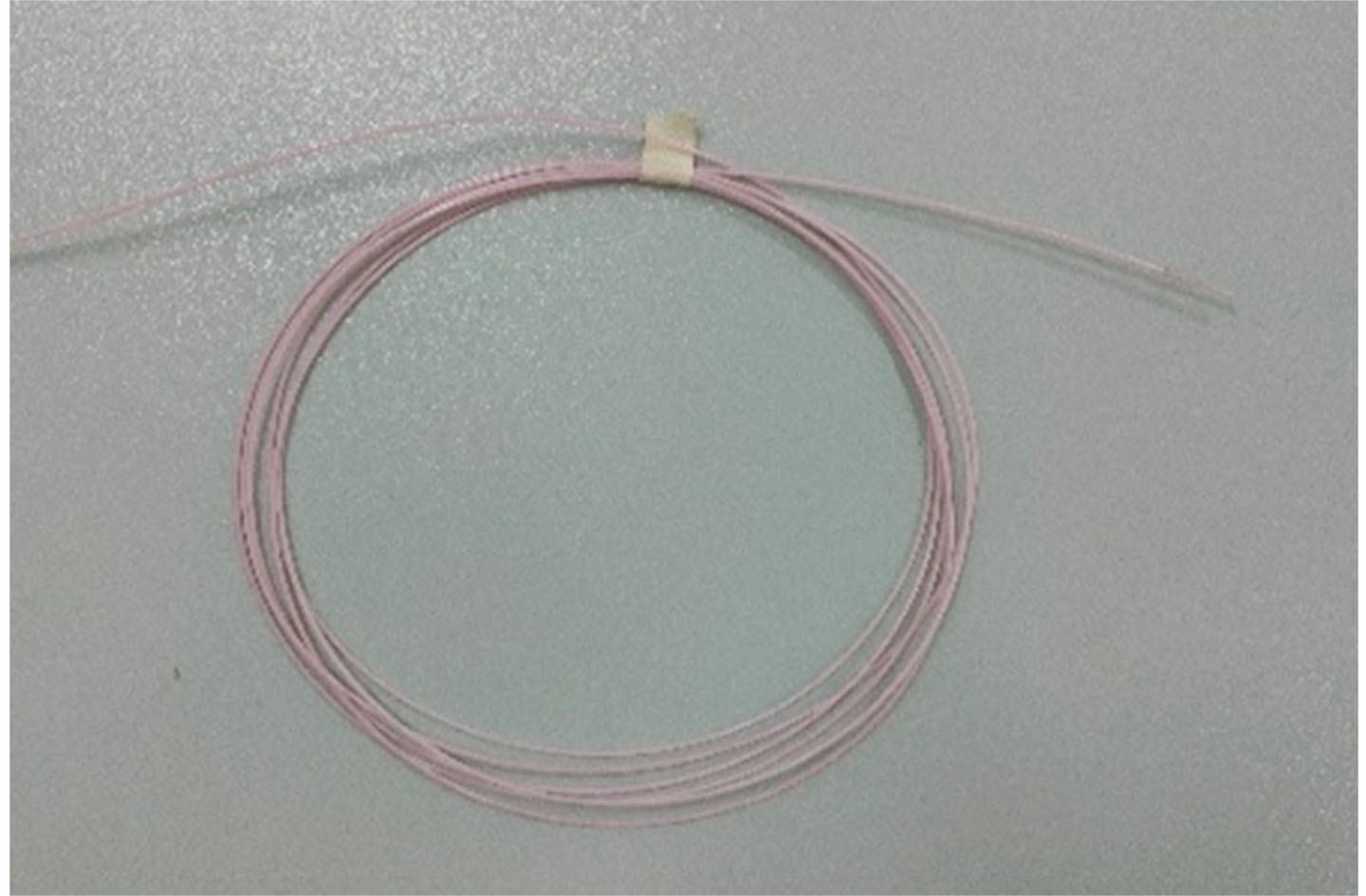

Fig. 2. Picture of optical cable

Fig. 3. OFDR demodulation instrument

Fig. 4. Schematic of fiber arrangement. (a) Before cracking; (b) after cracking

Fig. 5. Strain curves. (a) 1 cm spatial resolution; (b) 5 mm spatial resolution; (c) 2 mm spatial resolution

Fig. 6. Comparison of monitoring results under three spatial resolutions

Fig. 7. Comparison of measured and real values of crack width

Fig. 8. Experimental scheme. (a) Actual picture; (b) schematic diagram

Fig. 9. Cracking diagram of concrete beam bottom

Fig. 10. Strain of fiber 1 at each loading level

Fig. 11. Strain of fiber 2 at each loading level

Fig. 12. Width of crack 4 at each loading level

Fig. 13. Pictures of cracks. (a) Crack with 0.10 mm width; (b) crack with 0.22 mm width; (c) crack with 0.34 mm width

|

Table 1. Distance to fixed end

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Table 2. Comparison of measured crack position data and measurement results of OFDR

|

Table 3. Comparison of actual and measured values of crack widths

Set citation alerts for the article

Please enter your email address