Min Li, Youmin Rong, Lu Wang, Jiajun Xu. Study on Microstructure and Mechanical Properties of Laser Welded Joints for Ultra-High Strength Steel 1700MS[J]. Laser & Optoelectronics Progress, 2023, 60(17): 1714004

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 60, Issue 17, 1714004 (2023)

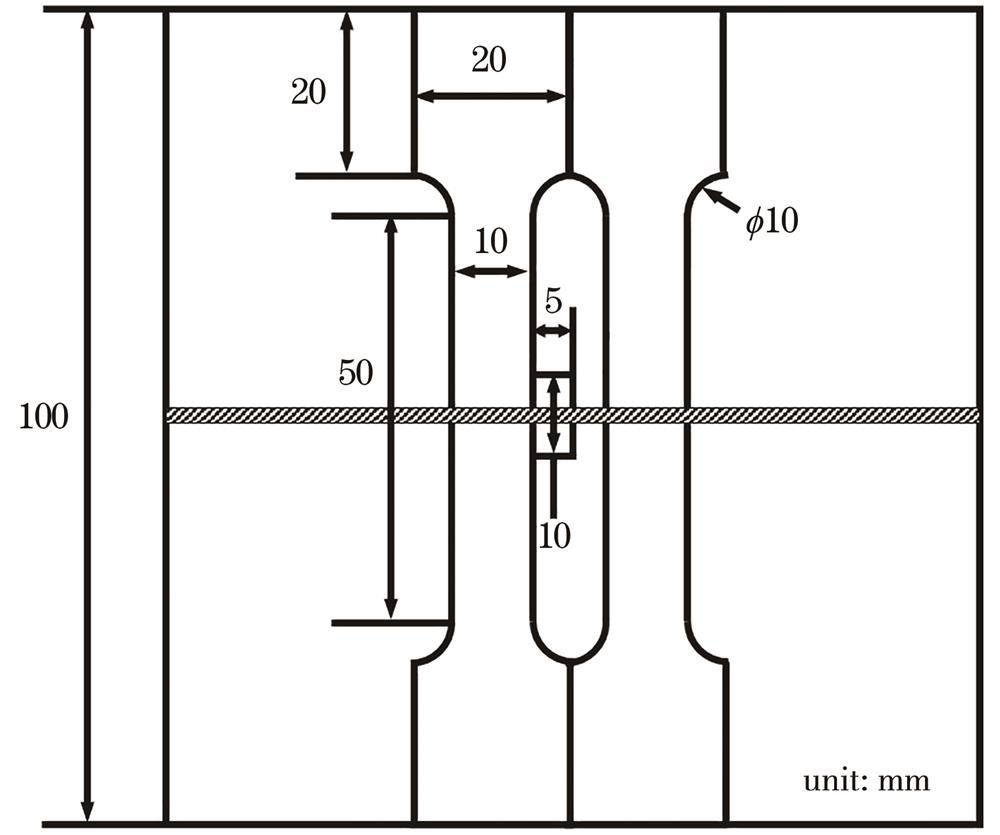

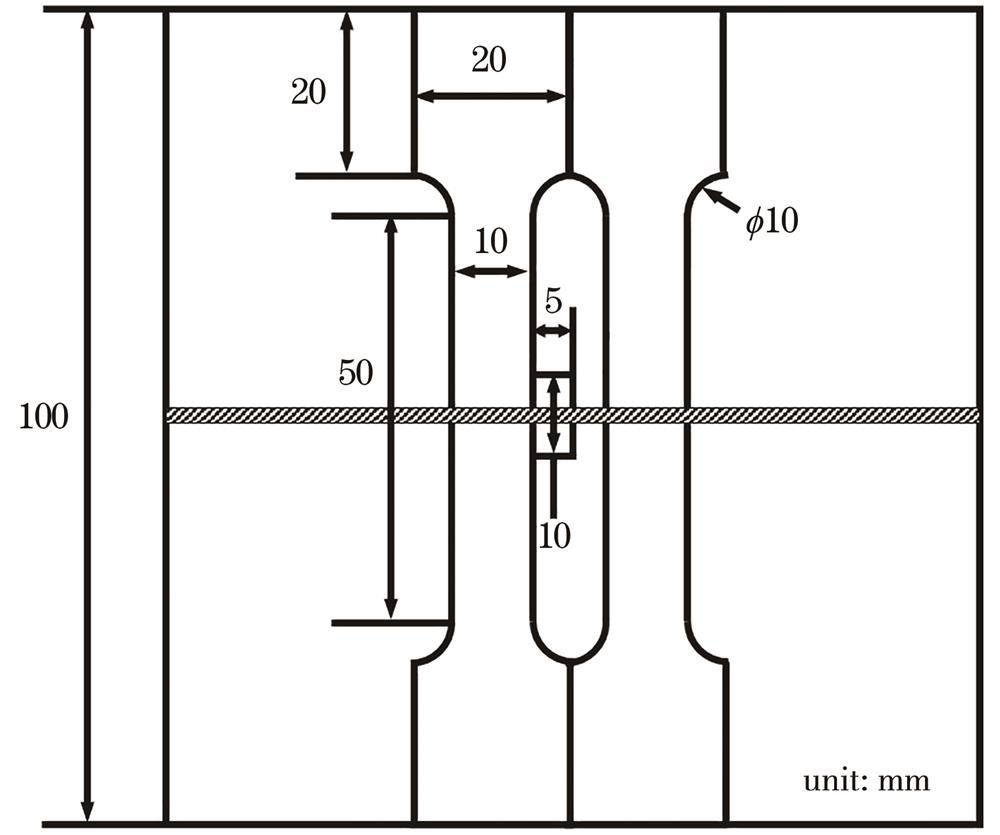

Fig. 1. Schematic diagram of tensile and metallographic specimens

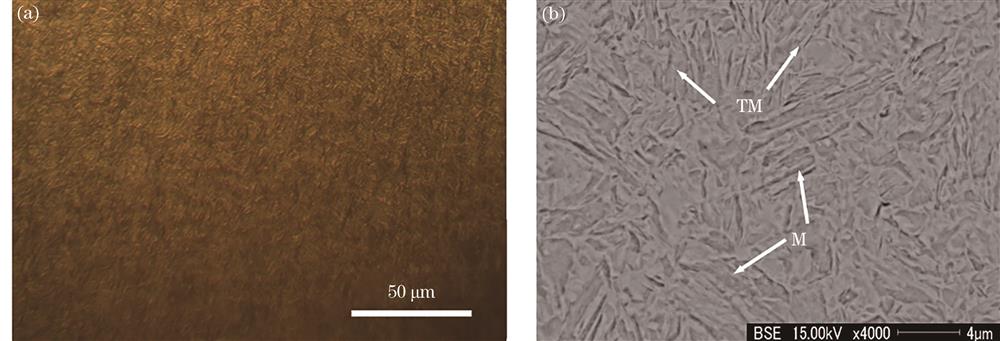

Fig. 2. Microstructure of martensitic steel 1700MS. (a) 500× optical microscope; (b) 4000× scanning electron microscope

Fig. 3. Weld morphologies at different welding speeds. (a) 2.4 m/min; (b) 3.3 m/min; (c) 4.2 m/min; (d) 5.1 m/min; (e) 6.0 m/min; (f) 6.9 m/min[17]

Fig. 4. Schematic diagram of welding joint area division

Fig. 5. Microstructure of welded joint (500×). (a) FZ; (b) CGHAZ; (c) FGHAZ; (d) ICHAZ; (e) SCHAZ I; (f) SCHAZ II

Fig. 6. Microhardness test results of welded joint. (a) Hardness test path; (b) microhardness curve

Fig. 7. Test results. (a) Stress-strain curves; (b) curve of tensile strength versus welding speed; (c) curve of elongation versus welding speed

|

Table 1. Mechanical properties of martensitic steel 1700MS[17]

|

Table 2. Chemical composition of martensitic steel 1700MS [17]

|

Table 3. Welding process parameters[17]

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||

Table 4. Change of widths of FZ, UCHAZ, and ICHAZ with welding speed

|

Table 5. Change of tensile strength with welding speed

Set citation alerts for the article

Please enter your email address