Shipeng Liu, Fengxi Li, Zhenhong Xing, Bingjun Cui, Shuyi Dai. Fabrication of Medical Titanium Alloy Microhole Array Substrates Based on High-Speed Polygon Mirror[J]. Laser & Optoelectronics Progress, 2022, 59(17): 1714002

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 59, Issue 17, 1714002 (2022)

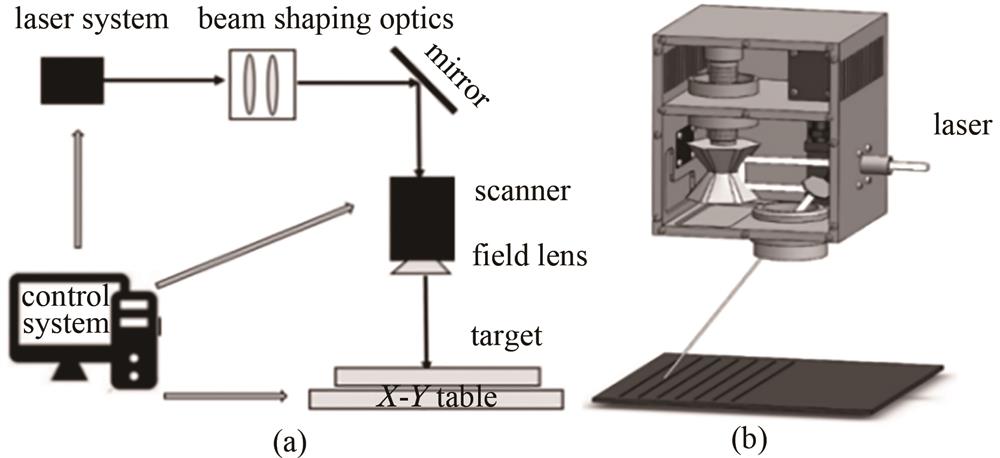

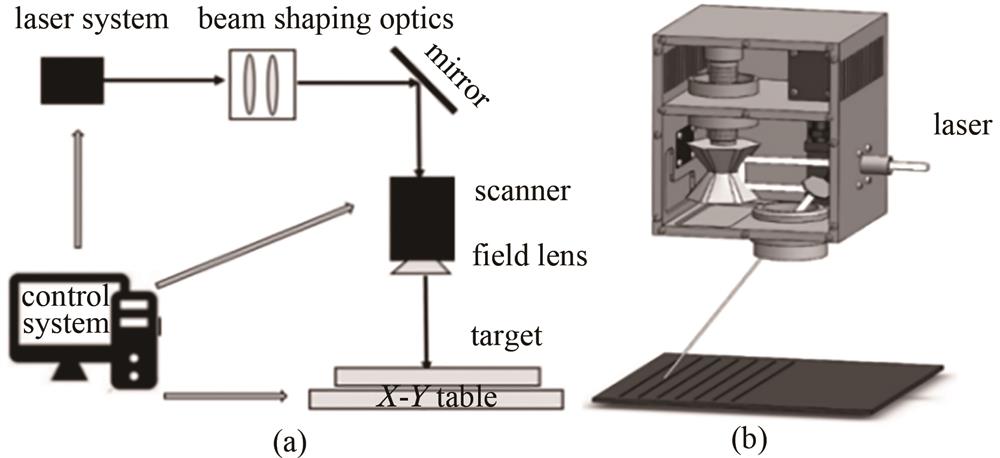

Fig. 1. Test setup diagram. (a) Experimental processing system; (b) high-speed polygon mirror scanning device

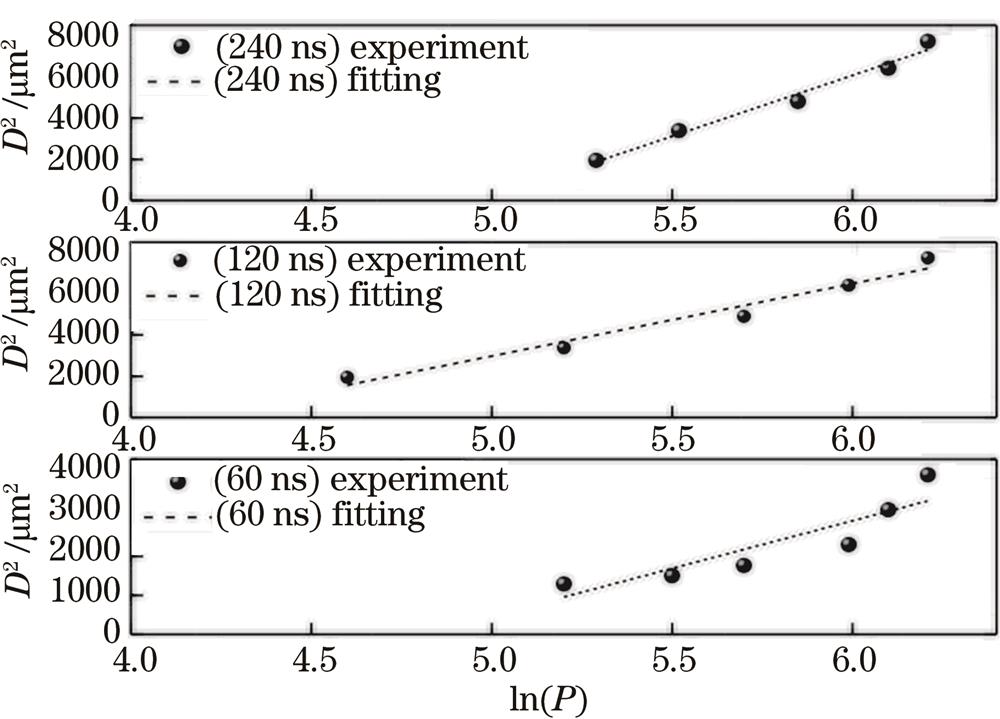

Fig. 2. Relationship between burning aperture and logarithm of power

Fig. 3. Variation of burning aperture with increasing laser power

Fig. 4. Variation curves of hole inlet diameter, outlet diameter, and hole taper of 0.1 mm titanium alloy with laser incident power

Fig. 5. Variation of laser drilling depth and morphology with increasing laser power

Fig. 6. High-speed polygon mirror laser processing 0.3 mm titanium alloy micro group holes substrate. (a) Microhole arrays arrangement; (b) microhole arrays dislocation arrangement

Fig. 7. Variation of hole morphology with scanning speed. (a) Scanning speed is 160 m/s; (b) scanning speed is 500 m/s

Fig. 8. Medical titanium alloy microhole substrate covered and filled with povidone

Fig. 9. Quincunx spot structure

Fig. 10. Aperture comparison before and after process optimization. (a) Before optimization; (b) after optimization

|

Table 1. Specific parameters of laser

|

Table 2. Specific parameters of scanning device

|

Table 3. Efficiency of micro group holes processed by the high-speed polygon mirror

Set citation alerts for the article

Please enter your email address