Qiang Zeng, Shaowei Zhu, Zhenghong Fu. Effects of Different Welding Processes on Microstructure and Mechanical Properties of SUS301L-MT Stainless Steel Joints[J]. Laser & Optoelectronics Progress, 2018, 55(3): 031405

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 55, Issue 3, 031405 (2018)

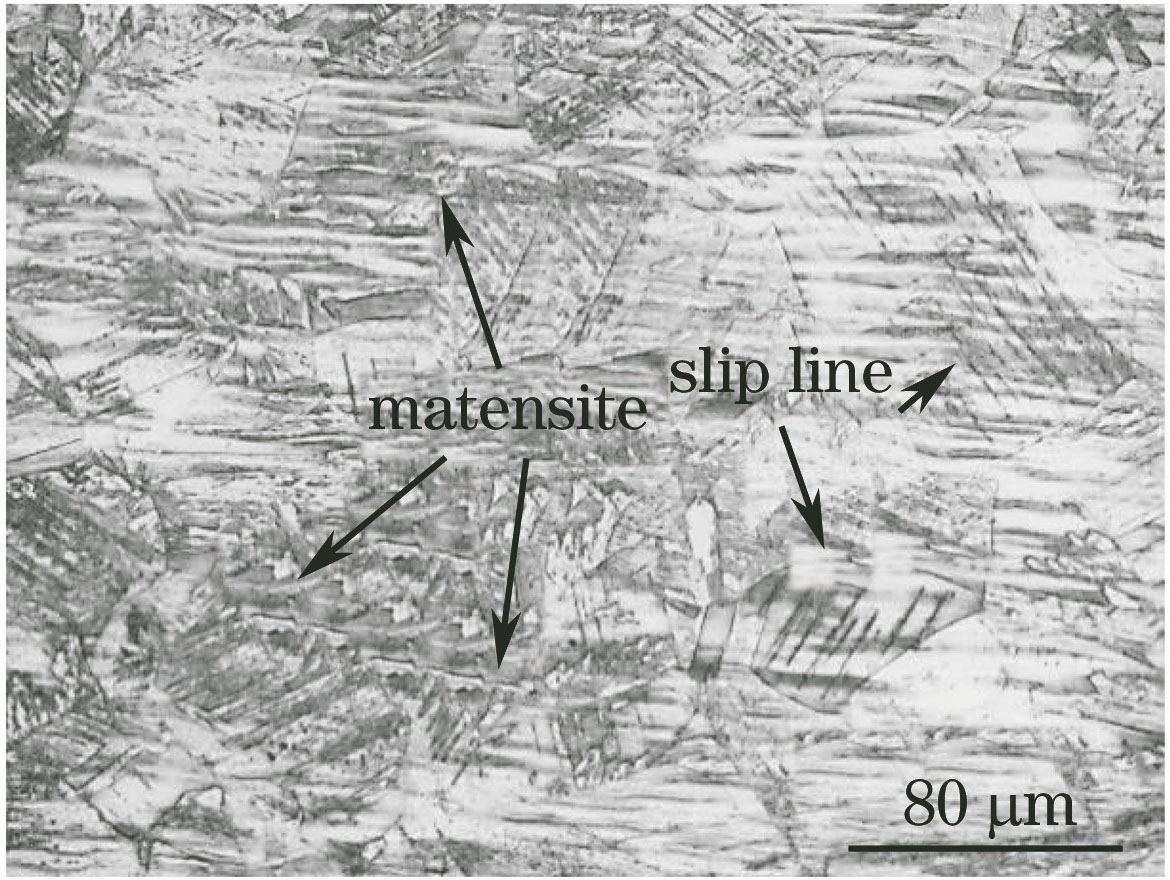

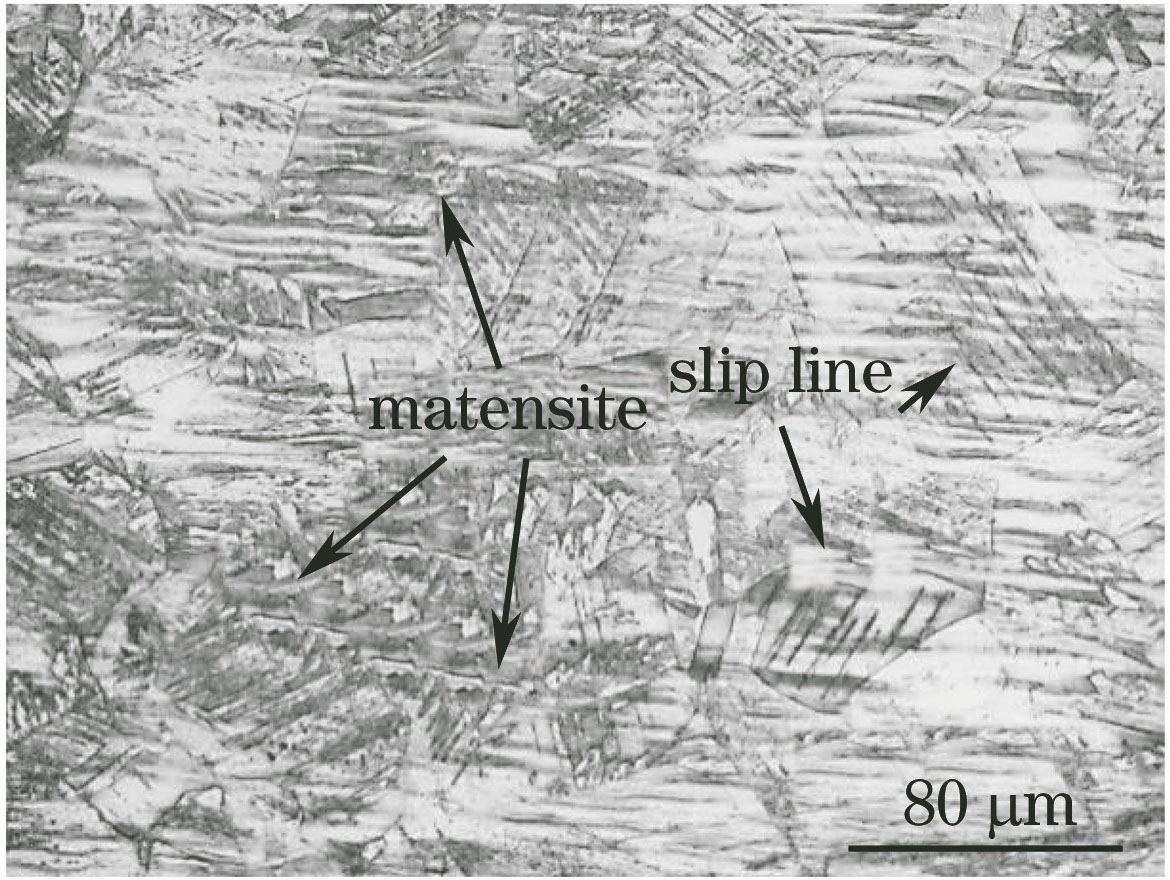

Fig. 1. Metallographic structure of SUS301L-MT stainless steel

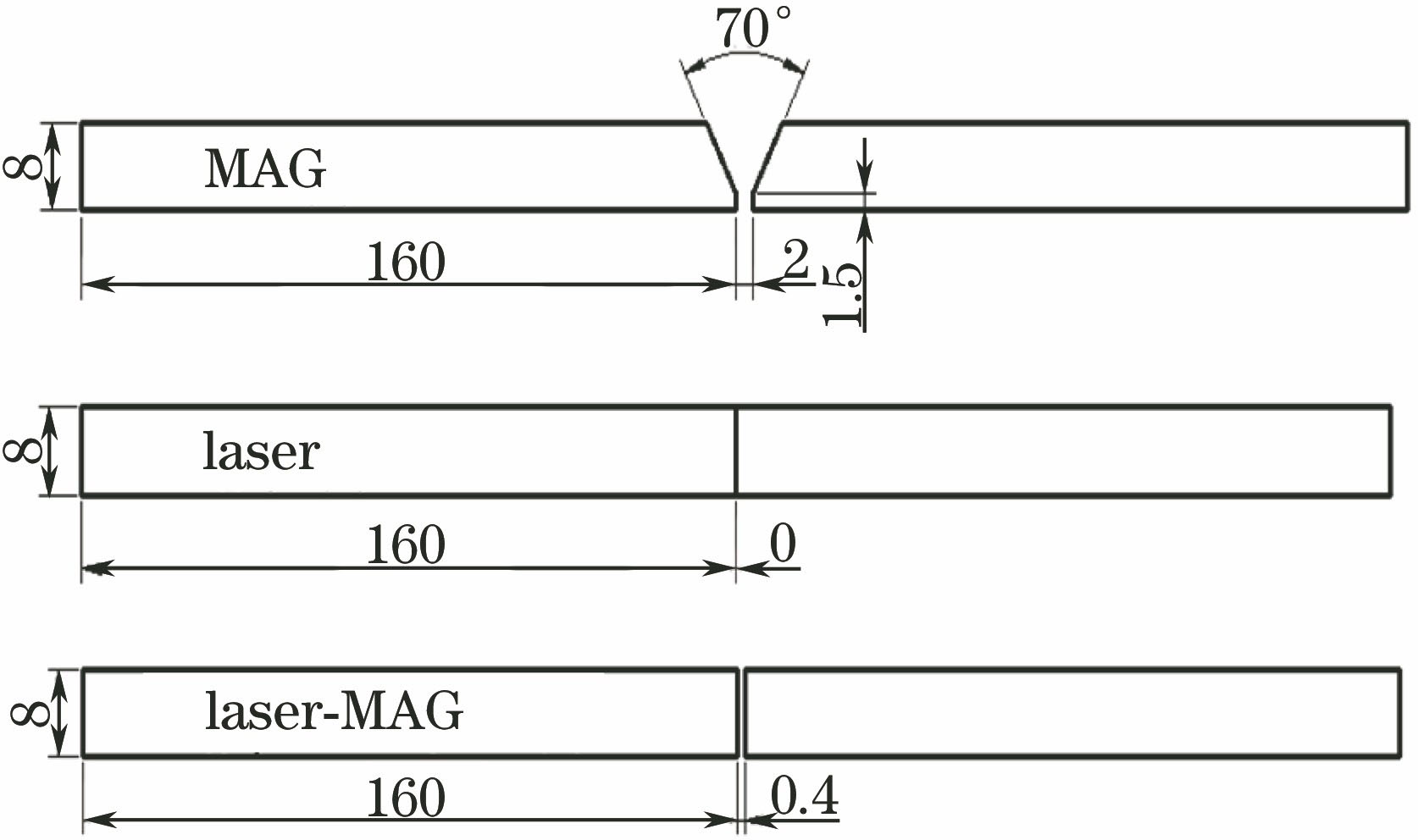

Fig. 2. Groove design under different welding processes

Fig. 3. Macrostructures of joints under different welding processess. (a) MAG welding; (b) laser welding; (c) laser-MAG hybrid welding

Fig. 4. XRD results of weld zones of joints under different welding processes

Fig. 5. Microstructures of weld zones under different welding processes. (a) MAG welding; (b) laser welding; (c) laser-MAG hybrid welding

Fig. 6. Microstructures of heat affected zones under different welding processes. (a) MAG welding; (b) laser welding; (c) laser-MAG hybrid welding

Fig. 7. Pseudo-phase diagram of stainless steel for Fe with mass fraction of 70%

Fig. 8. Hardness distributions at different positions of joints. (a) Top, (b) bottom

Fig. 9. Residual stress distributions of joints under different welding processes. (a) Longitudinal; (b) transverse

Fig. 10. Strength comparison of joints under different welding processes

Fig. 11. Fracture morphologies of joints under different welding processes. (a) Laser-MAG hybrid welding; (b) laser welding; (c) MAG welding

|

Table 1. Chemical compositions of SUS301L-MT stainless steel and ER308L Si welding wire (mass fraction, %)

Set citation alerts for the article

Please enter your email address