Sanfeng HAO, Jian ZHANG, Jianfeng YANG. F/0.78 High Order Aspheric Surface Testing with Null Compensator and Mapping Distortion Correction[J]. Acta Photonica Sinica, 2023, 52(2): 0212004

Search by keywords or author

- Acta Photonica Sinica

- Vol. 52, Issue 2, 0212004 (2023)

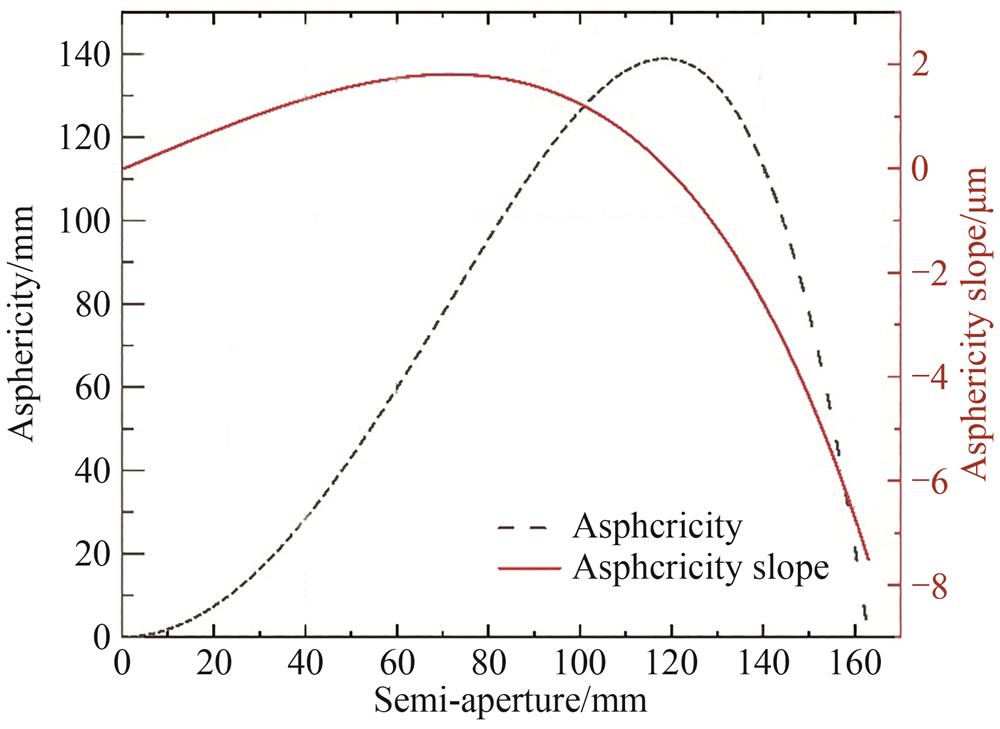

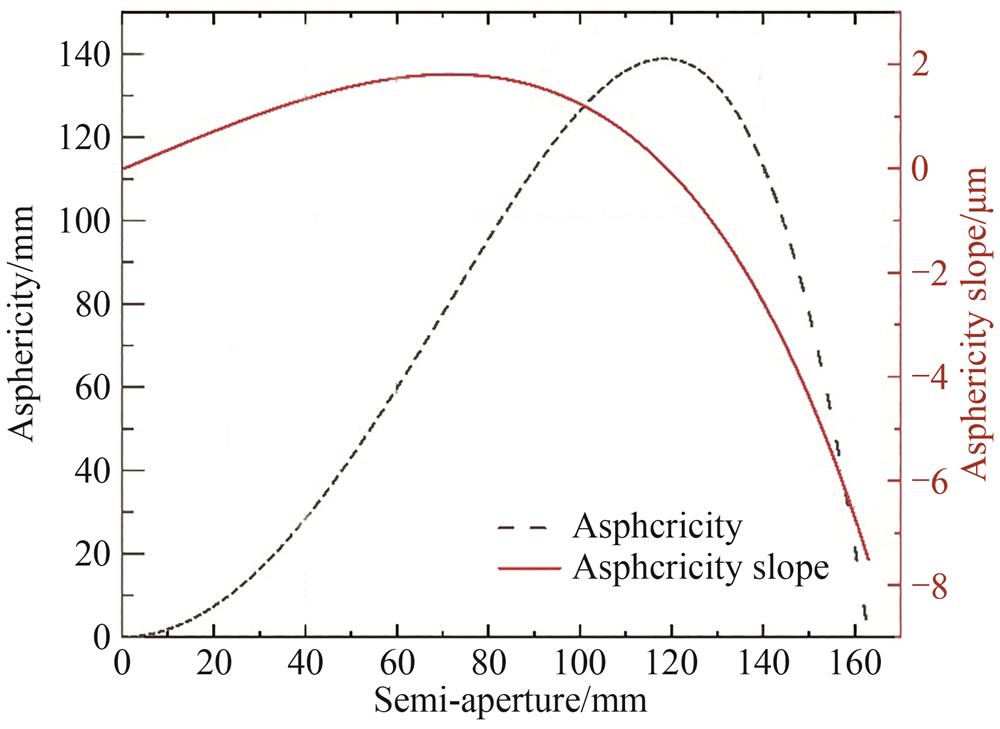

Fig. 1. Plot of the asphericity and asphericity slope

Fig. 2. High order aspheric surface testing with three-piece lens null compensator

Fig. 3. The interactive interface of initial structural parameters calculation program

Fig. 4. Optical layout with initial structure parameters

Fig. 5. The final design results of three-piece lens compensator

Fig. 6. High-order aspheric surfaces testing with three-piece lens compensator

Fig. 7. High-order aspheric surface imaging with null lens compensator

Fig. 8. Schematic diagram of distortion principle

Fig. 9. Mapping distortion correction of interferometeric map

Fig. 10. Optical deterministic polishing based on distortion correction map

|

Table 1. Parameters of high-order aspheric surface

|

Table 2. Structure data of null lens compensator

|

Table 3. Tolerances and error budget for null lens compensator

|

Table 4. Tolerances of null lens compensator

|

Table 5. Parameters of ZYGO transmission spheres for testing surface irregularity of null lens compensator

Set citation alerts for the article

Please enter your email address