Linfeng ZHOU, Guoqiang FU, Zhengtang LI, Guoqiang LEI, Xiaolei DENG. General-purpose temperature sensitive point combination selection for thermal error of machine tool spindle[J]. Optics and Precision Engineering, 2022, 30(12): 1462

Search by keywords or author

- Optics and Precision Engineering

- Vol. 30, Issue 12, 1462 (2022)

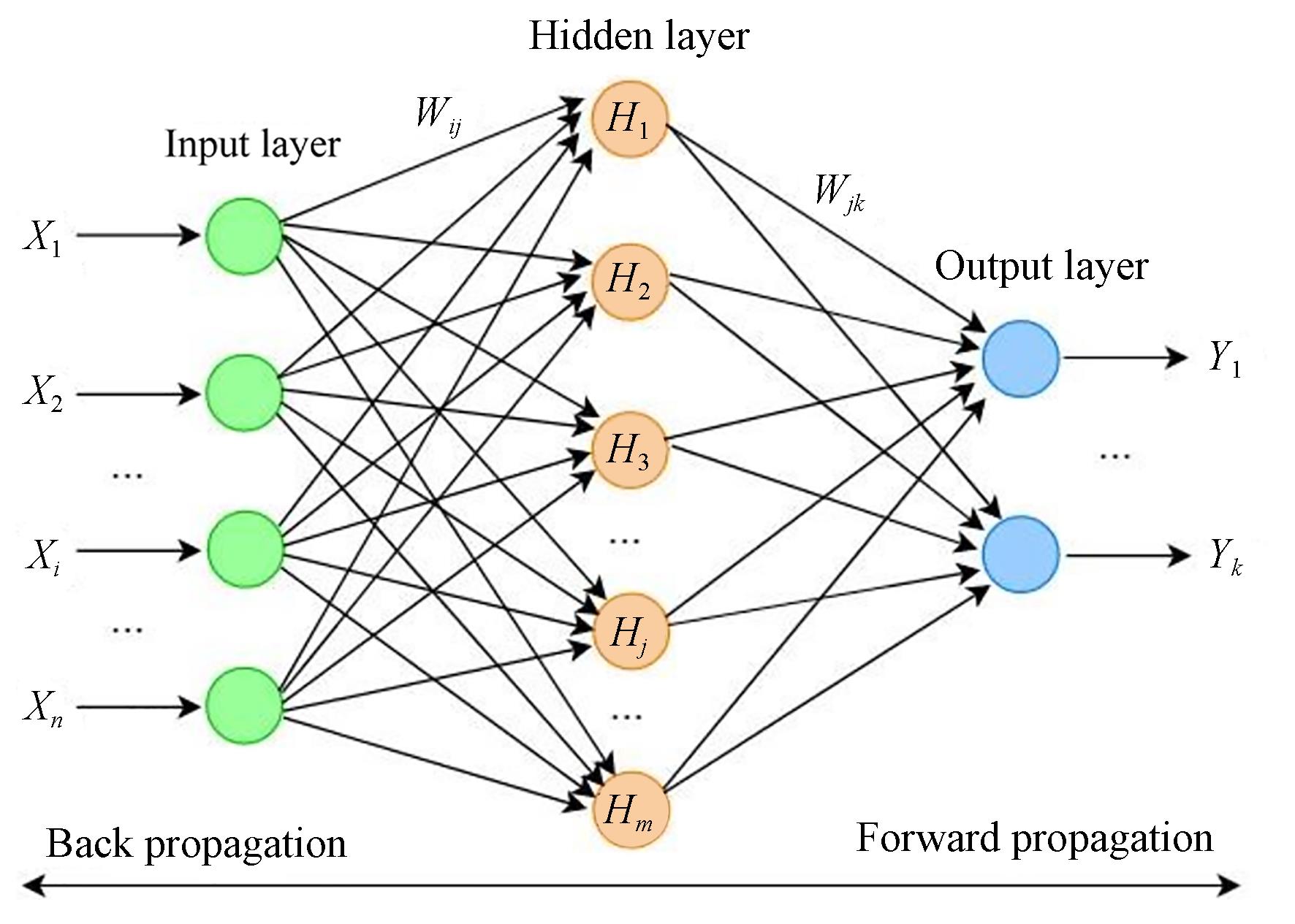

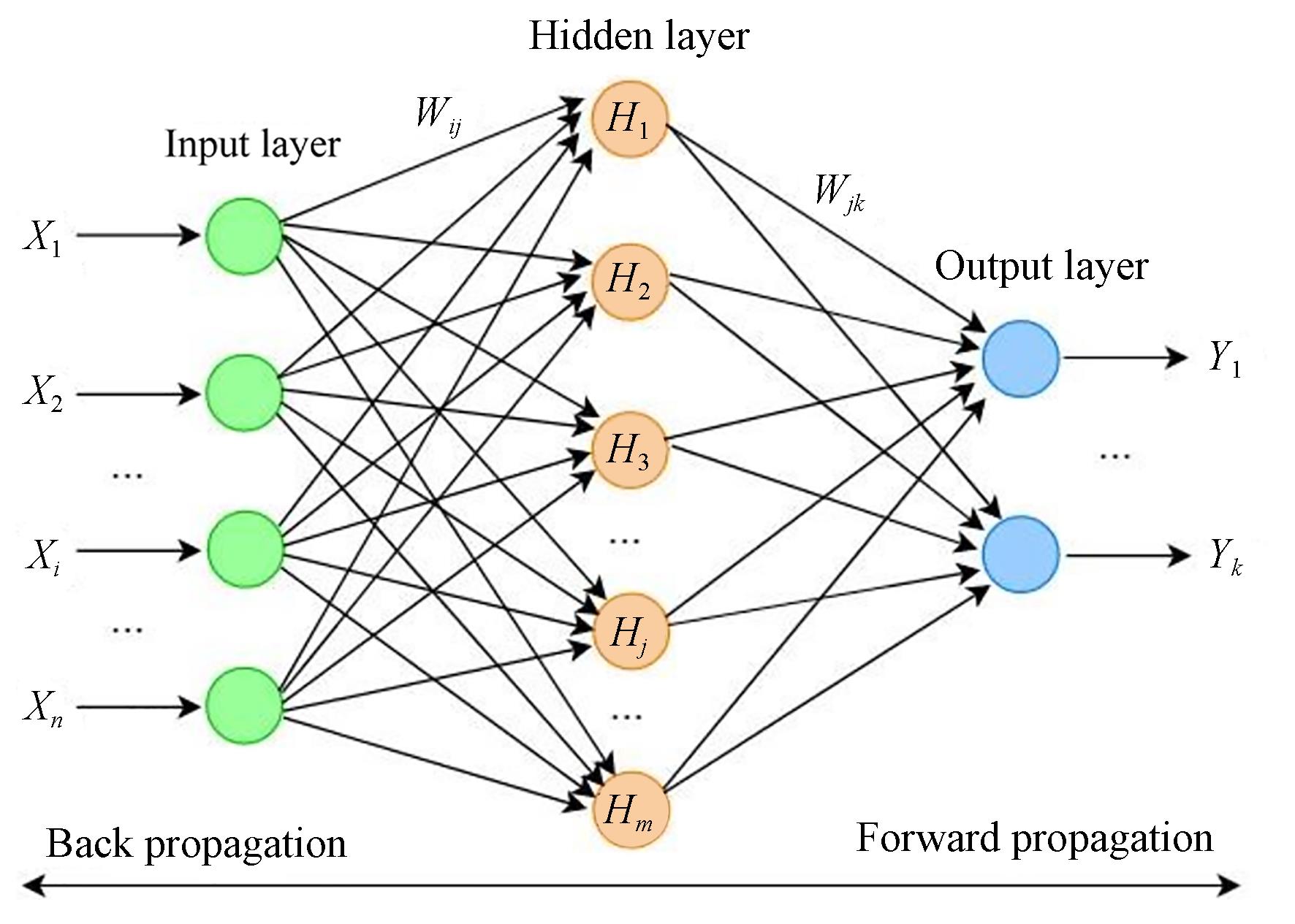

Fig. 1. Structure diagram of BP neural network

Fig. 2. VMC850 machining center test site

Fig. 3. Sensor location

Fig. 4. Partial temperature data and thermal deformation at 2 500 r/min

Fig. 5. Flow chart of comprehensive selection method for optimal temperature sensitive points

Fig. 6. Thermal error residual curve of X 2 corresponding to different K values at 2 500 r/min

Fig. 7. Prediction performance evaluation results of various thermal errors of BP model

Fig. 8. Thermal error prediction residual of X 1 corresponding to part of K values at 2 500 r/min

Fig. 9. Thermal error prediction result of Z corresponding to the combination of different temperature sensitive points at 2 000 r/min

Fig. 10. Prediction residual of thermal error of Z corresponding to part temperature sensitive points combination at 3 000 r/min

Fig. 11. Prediction residual of part temperature sensitive point combination corresponding to thermal error of Z at 5 000 r/min

Fig. 12. Thermal error predictive results of thermal error of Z of RBF model corresponding to part of sensitive temperature points at 2 500 r/min

Fig. 13. Thermal error predictive results of thermal error of Z of SVM model corresponding to part of sensitive temperature points at 2 500 r/min

Fig. 14. Thermal error predictive results of thermal error of Z of MLR model corresponding to part of sensitive temperature points at 2 500 r/min

|

Table 1. Specific distribution of temperature sensors

|

Table 2. Design of thermal error experimental conditions

|

Table 3. Absolute average correlation coefficient of temperature and thermal error data at 2 500 r/min speed

|

Table 4. Clustering results of temperature variables corresponding to different K values

|

Table 5. Combination of temperature sensitive points corresponding to different K values at 2 500 r/min speed

|

Table 6. Absolute residual and absolute root mean square deviation calculation results

|

Table 7. Prediction performance evaluation results of thermal error of X 1

|

Table 8. Evaluation results of different K values of thermal error of Z at 2 000 r/min

|

Table 9. Evaluation results of different K values of Z directions at 3 000 r/min

|

Table 10. Evaluation results of different K values of thermal error of Z at 5 000 r/min

|

Table 11. Evaluation results of RBF model prediction performance corresponding to different K values at 2 500 r/min

|

Table 12. Evaluation results of SVM model prediction performance corresponding to different K values at 2 500 r/min

|

Table 13. Evaluation results of SVM model prediction performance corresponding to different K values at 2 500 r/min

Set citation alerts for the article

Please enter your email address