Zhihui Luo, Jie Gao, Shaohua Deng, Xiaolong Wang, Yunrui He. A Metal Strain Rosette Sensor Using Ultra-Weak Fiber Bragg Grating[J]. Laser & Optoelectronics Progress, 2025, 62(5): 0506006

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 62, Issue 5, 0506006 (2025)

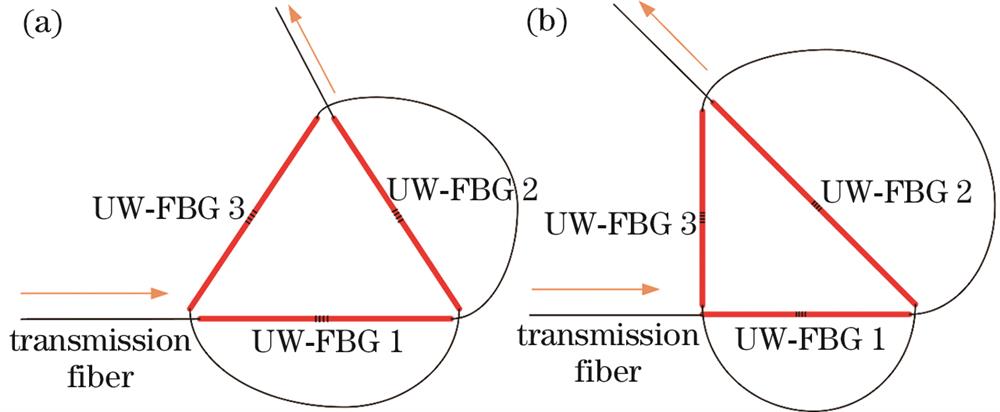

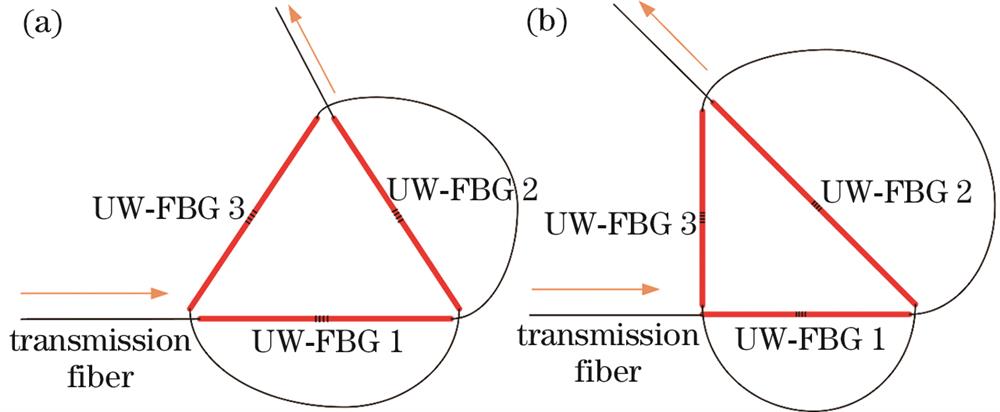

Fig. 1. Three-way strain rosette structures of UW-FBG fiber. (a) Equilateral triangle; (b) right triangle

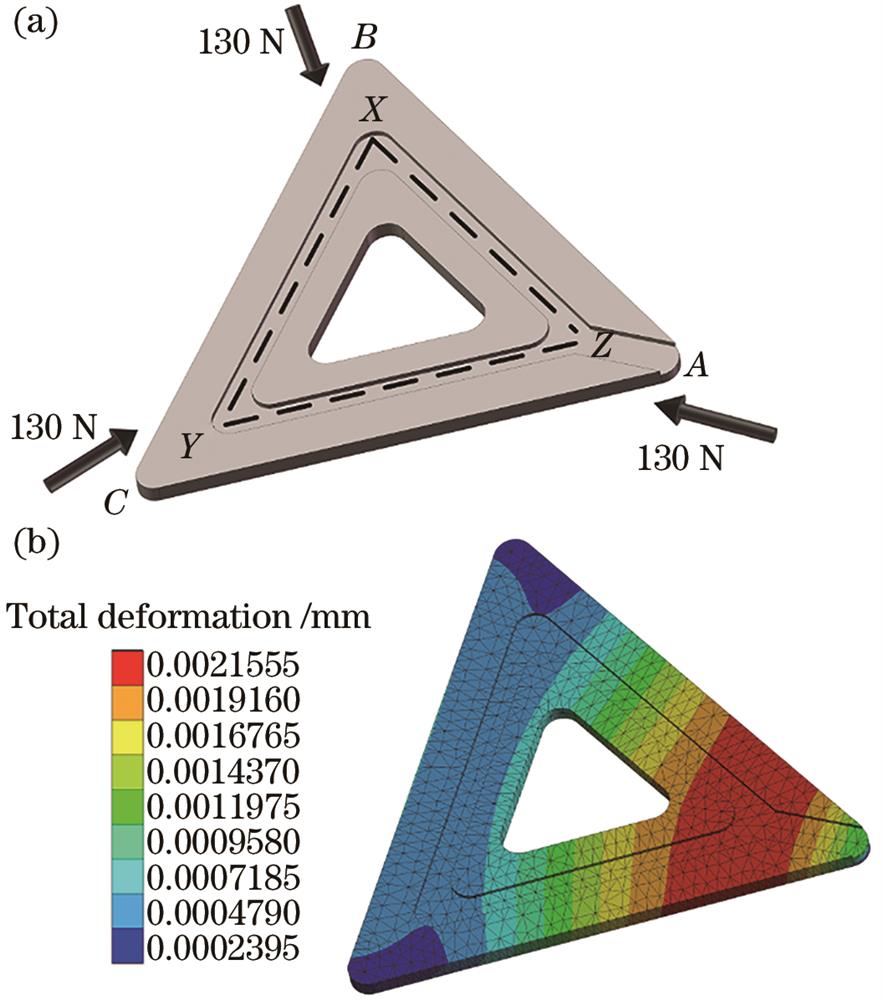

Fig. 2. Simulation of metal strain rosette substrate. (a) Schematic diagram of force; (b) simulated result

Fig. 3. Deformations of different substrate models. Variation in deformations of (a) XY groove, and (b) XZ groove with groove depth when substrate thickness is 1.0 mm,and length of triangle side is 16 mm; variation in deformations of (c) XY groove, and (d) XZ groove with substrate thickness when groove depth is 0.5 mm, and length of triangle side is 16 mm; variation in deformations of (e) XY groove, and (f) XZ groove with length of triangle side when substrate thickness is 1.0 mm, and groove depth is 0.5 mm

Fig. 4. Multi-factor histogram of deformation for different models. (a) Deformation of bottom; (b) deformation of side

Fig. 5. Dimension of metal strain rosette substrate

Fig. 6. UW-FBG metal strain rosette sensor. (a) Overall structure of sensor; (b) schematic diagram of welding

Fig. 7. Designed simulation of different spot welding methods

Fig. 8. Forcing experiment system of strain rosette sensor

Fig. 9. Fitted curves of load and wavelength shift in OAB direction. (a) Test 1; (b) test 2; (c) test 3

Fig. 10. Fitted curves of load and wavelength shift in XYZ direction. (a) Test 1; (b) test 2; (c) test 3

Fig. 11. Tensile experiment system of strain rosette sensor

Fig. 12. Fitted curves of load and wavelength shift in tensile experiments. (a) Test 1; (b) test 2; (c) test 3

Fig. 13. Fitted curves of temperature and wavelength for strain rosette sensor

Fig. 14. Physical drawing of model test

Fig. 15. Fitted curves of load for different devices and wavelength shift or strain. (a) Fitted curves of load for strain rosette sensor and wavelength shift; (b) fitted curves of load for strain gauge and strain; (c) fitted curves of load for optic cable and wavelength shift

|

Table 1. Designed substrate models

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Table 2. Simulation results of 6 types for spot welding methods

| ||||||||||||||||||||||||||||||||

Table 3. Measure results in OAB angular

| ||||||||||||||||||||||||||||||||

Table 4. Measure results in XYZ angular

| ||||||||||||||||||||||||||||||||

Table 5. Measurement results of tensile experiments

Set citation alerts for the article

Please enter your email address