Dewei Deng, Junyu Wang, Fanmin Meng, Hongming Wan, Qi Sun, Yong Zhang. Laser Remelting Effect on Casting and CMT Surfacing Babbitt Metal Microstructure[J]. Laser & Optoelectronics Progress, 2023, 60(15): 1514010

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 60, Issue 15, 1514010 (2023)

Fig. 1. Babbitt sample. (a) (b) Babbitt metal of casting; (c) (d) Babbitt metal of CMT surfacing

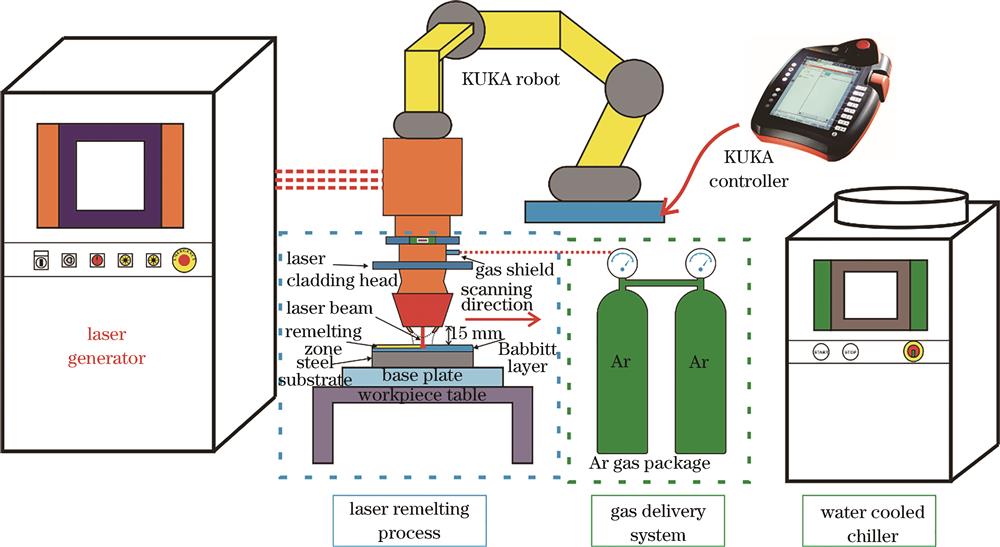

Fig. 2. Laser remelting equipment

Fig. 3. Sample preparation process

Fig. 4. Surface and interface microstructure of Babbitt metal. (a) (b) Babbitt metal of casting; (c) (d) Babbitt metal of CMT surfacing

Fig. 5. SEM morphology of cross-section of Babbitt metal specimens. (a) (b) Babbitt metal of casting;(c) (d) Babbitt metal of CMT surfacing

Fig. 6. Curves of element diffusion in Babbitt metal interface. (a) Babbitt metal of casting; (b) Babbitt metal of CMT surfacing

Fig. 7. Surface morphology of Babbitt metal after laser remelting

Fig. 8. Microstructure of Babbitt metal of casting after laser remelting. (a)-(e) Sample 1#-5#

Fig. 9. Microstructure of Babbitt metal of CMT surfacing after laser remelting. (a)-(e) Sample 6#-10#

Fig. 10. SEM morphology of Babbitt metal. (a) Babbitt metal of casting; (b) (c) Babbitt metal of casting after laser remelting (laser power is 500 W); (d) Babbitt metal of CMT surfacing; (e) (f) Babbitt metal of CMT surfacing after laser remelting (laser power is 300 W and 500 W)

Fig. 11. Histogram of Babbitt hardness

Fig. 12. Hardness change curves of interface. (a) Babbitt metal of casting; (b) Babbitt metal of CMT surfacing

Fig. 13. Hardness curves of Babbitt metal after laser remelting

| |||||||||||||||||||||||||||||||||||||||||||

Table 1. Chemical composition of Sn-11Sb-6Cu

| ||||||||||||||||||||||||||||||||||||||||||||

Table 2. Element composition of EDS point scanning

| |||||||||||||||||||||||||||||||||

Table 3. Laser remelting parameters of 1#-10# Babbitt alloy samples

Set citation alerts for the article

Please enter your email address