Weichen XU, Haiyang ZHANG, Changming ZHAO. Thermal effect analysis of all-solid-state solar pumped laser[J]. Journal of Applied Optics, 2023, 44(6): 1219

Search by keywords or author

- Journal of Applied Optics

- Vol. 44, Issue 6, 1219 (2023)

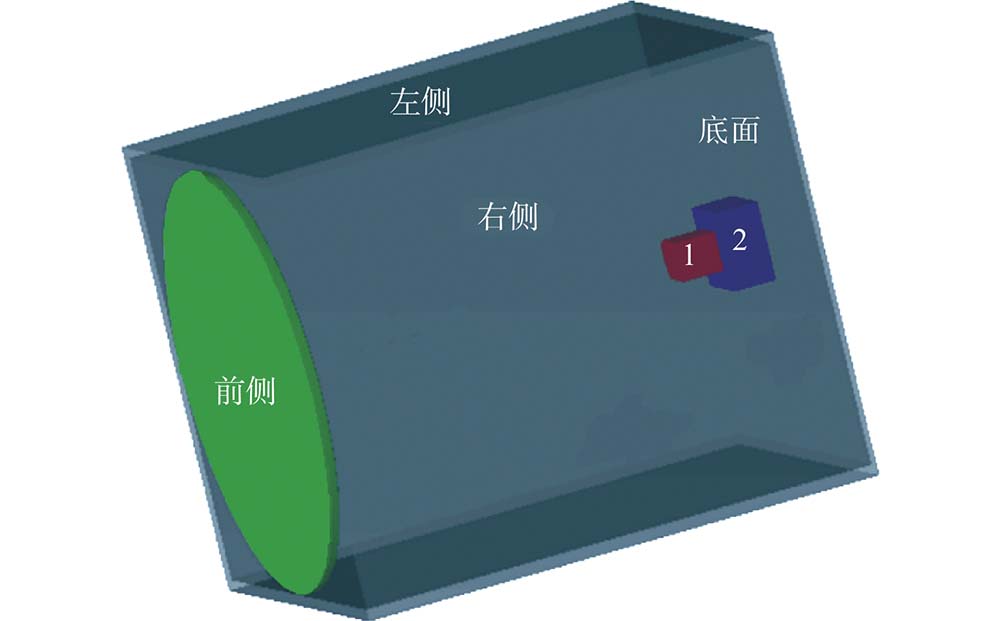

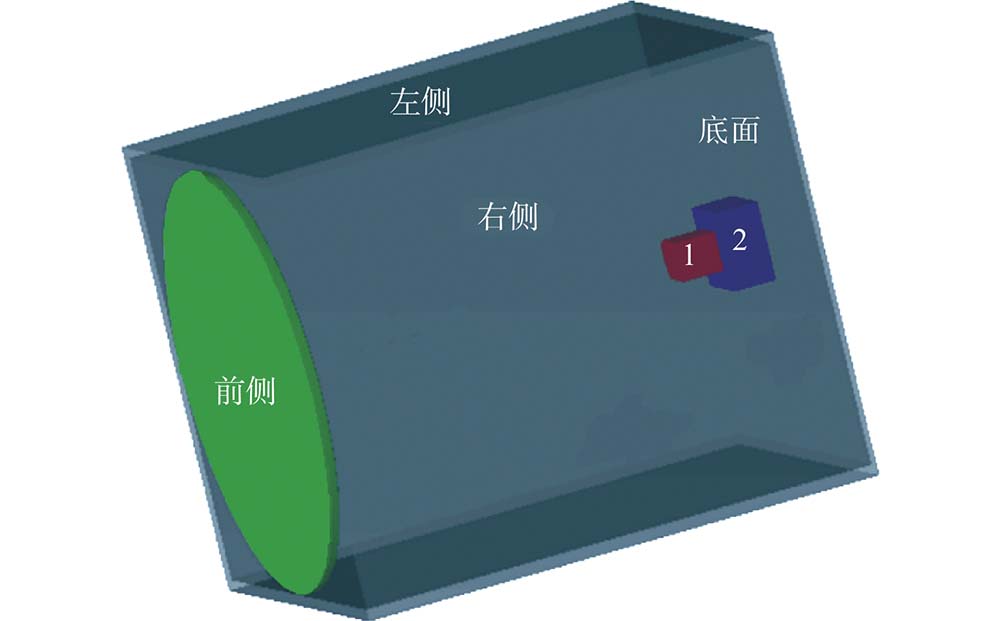

Fig. 1. Simplified thermal analysis model of all-solid-state solar pumped laser

Fig. 2. Solar emission spectrum

Fig. 3. Steady-state temperature distribution diagram of Fresnel lens

Fig. 4. Irradiance distribution diagram of front surface of conical cavity

Fig. 5. Diagram of steady-state thermal analysis results (contour map)

Fig. 6. Heat distribution curves of crystal rod and conical cavity

Fig. 7. Solar irradiance distribution diagram

Fig. 8. Diagram of steady-state thermal analysis results

Fig. 9. Solar irradiance distribution diagram

Fig. 10. Diagram of steady-state thermal analysis results

Fig. 11. Solar irradiance distribution diagram

Fig. 12. Diagram of steady-state thermal analysis results

Fig. 13. Diagram of steady-state thermal analysis results

Fig. 14. Diagram of steady-state thermal analysis results

Fig. 15. Diagram of steady-state thermal analysis results

Fig. 16. Diagram of steady-state thermal analysis results

|

Table 1. Materials and corresponding thermal conductivity of each part of simplified laser model

|

Table 2. Solar ray tracing irradiance distribution

|

Table 3. Summary of results

|

Table 4. Summary of results

Set citation alerts for the article

Please enter your email address