Meimei Kong, Shicheng Pan, Dong Yuan, Xiaobo Sun, Yinyan Xue, Rui Zhao, Tao Chen. Design and Analysis of Aspheric Liquid Lens with Square Cavity Structure[J]. Laser & Optoelectronics Progress, 2023, 60(21): 2122005

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 60, Issue 21, 2122005 (2023)

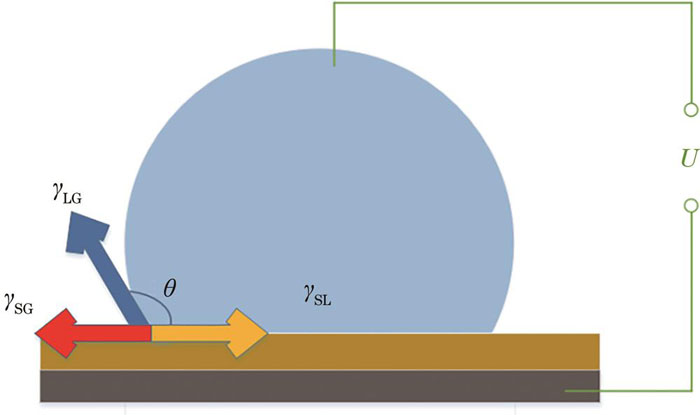

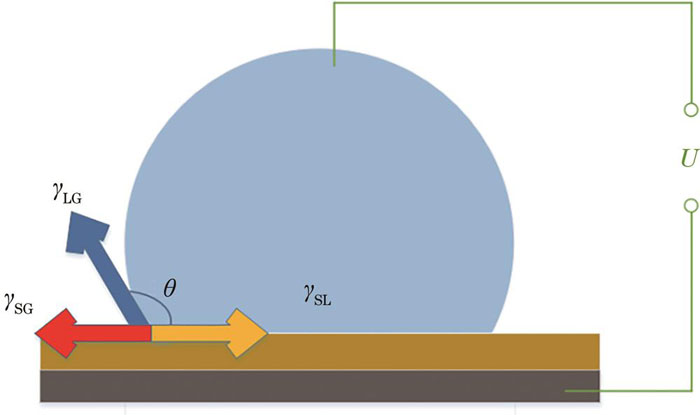

Fig. 1. Schematic diagram of dielectric wetting structure

Fig. 2. Square cavity structure model of double liquid structure. (a) Cross section of square cavity; (b) stereogram

Fig. 3. Surface shape change driven by simultaneous voltage application on four walls. (a) 80 V; (b) 300 V

Fig. 4. Change of surface shape driven by different voltages applied to the front and rear walls at the same time. (a) 60 V; (b) 90 V; (c) 140 V

Fig. 5. Device fabrication diagrams. (a) Schematic diagram of the assembled outer cavity; (b) device structure

Fig. 6. Side view of liquid lens

Fig. 7. Surface shape change diagram under applied driving voltage. (a) 80 V; (b) 300 V

Fig. 8. Image processing result (taking the interface at 80 V as an example)

Fig. 9. Fitting diagrams of interface shape. (a) 80 V; (b) 300 V

| |||||||||||||||||||||||

Table 1. Fitting accuracy of four fitting formulas at different voltages

Set citation alerts for the article

Please enter your email address