Liufei Huang, Yaoning Sun, Guojian Wang. Research Progress of Laser Cladding High-Entropy Alloy Coating[J]. Laser & Optoelectronics Progress, 2019, 56(24): 240003

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 56, Issue 24, 240003 (2019)

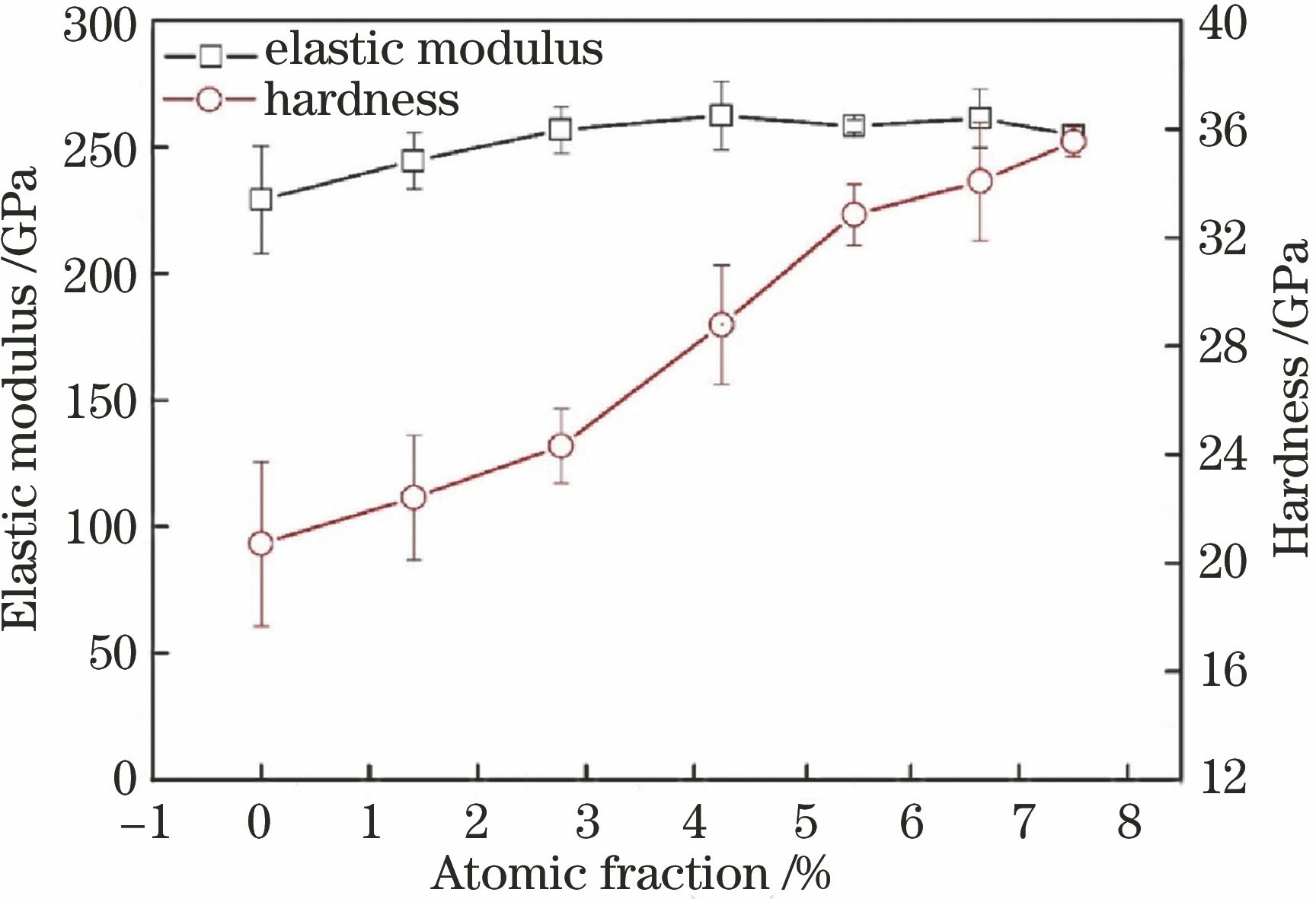

![Hardness and elastic modulus of nitride coatings with different Si contents[17]](/richHtml/lop/2019/56/24/240003/img_1.jpg)

Fig. 1. Hardness and elastic modulus of nitride coatings with different Si contents[17]

![Yield strength and density of high-entropy alloys and traditional alloys[10]](/richHtml/lop/2019/56/24/240003/img_2.jpg)

Fig. 2. Yield strength and density of high-entropy alloys and traditional alloys[10]

Fig. 3. Comparison of high-temperature compression performances of high-melting-point and high-entropy alloys and traditional nickel-based high-temperature alloys[26]

Fig. 4. Corrosion resistance of Alx CoCrFeNi high-entropy alloy and SS 304 stainless steel[30]. (a) Polarization curves at room temperature; (b) relation between soaking time and corrosion rate of Alx CoCrFeNi high-entropy alloy

Fig. 5. Comparison of wear resistance between Alx Co1.5CrFeNi1.5Tiy high-entropy alloy and traditional wear-resistant steel[34]

|

Table 1. Properties and usage frequency of component elements in high-entropy alloys[12]

Set citation alerts for the article

Please enter your email address