Shuhua Li, Yatong Zhou, Dan Wang, Jingfei He, Zhongwei Zhang. Surface Defect Detection of Polyvinyl Chloride Pipes Based on Machine Vision[J]. Laser & Optoelectronics Progress, 2019, 56(13): 131006

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 56, Issue 13, 131006 (2019)

Fig. 1. Surface detection platform of PVC pipes

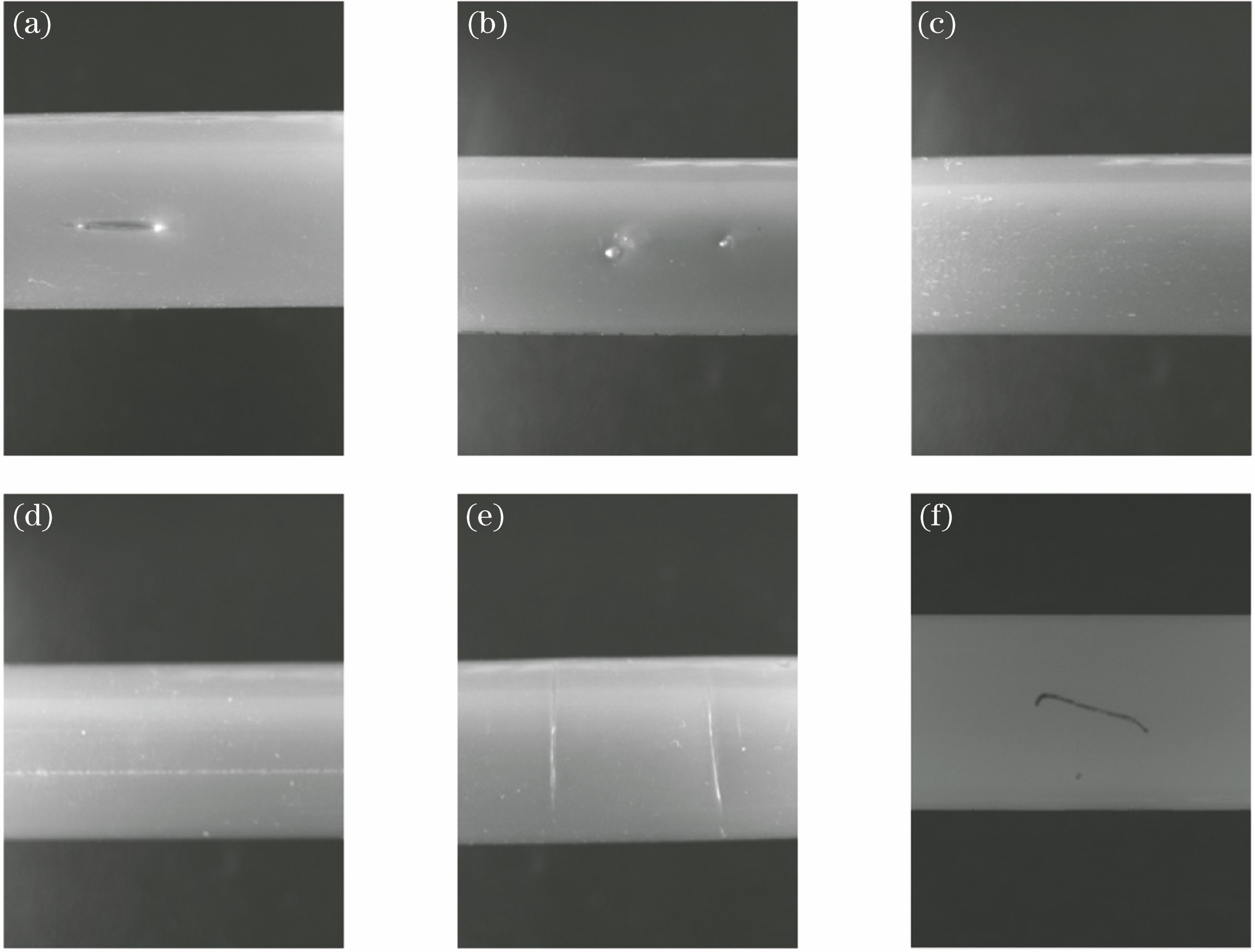

Fig. 2. Surface defects on PVC pipes. (a) Pits; (b) bubbles; (c) impurities; (d) wrinkles; (e) scratches; (f) pollution

Fig. 3. Table used to quickly look up Gamma transformation

Fig. 4. Gamma transformation and contrast diagrams. (a) Original image; (b) area of wrinkle; (c) image after Gamma transformation

Fig. 5. Vertical projection results of pipe

Fig. 6. Vertical first-order differential with five differences

Fig. 7. Schematic of fast region growing. (a) Growing point in original matrix; (b) growing results per line; (c) final growing result

Fig. 8. Effect of block processing. (a) Point defect; (b) block projection; (c) block first-order differential

Fig. 9. Test flow chart of surface detection platform of PVC pipes

Fig. 10. Detection results of surface defect online detection platform of PVC pipes. (a) Pits; (b) impurities; (c) bubbles; (d) wrinkles; (e) scratches; (f) pollution

|

Table 1. Comparison of time cost for Gamma transformation

|

Table 2. Comparison of time cost for region growing

Set citation alerts for the article

Please enter your email address