Journals >Chinese Journal of Lasers

In the selective laser melting (SLM) process, the stability of the melt pool plays a crucial role in determining the surface and internal quality of the formed parts. To address the limitations imposed by unstable factors during the SLM process, introducing in-process monitoring technology is essential. The technology can reveal the relationship between the melt pool radiation signals and the quality of the formed parts. By combining these signal characteristics with process parameters, it is possible to control the quality of the formed parts, which is of great significance to the advancement of SLM technology.

Based on the principle that metal powder absorbs laser energy and generates optical radiation upon melting during the SLM process, this study developed a coaxial in-situ monitoring device for SLM, utilizing photodiodes. This device captured the radiation time-series signals of the high-temperature melt pools during the printing process that was carried out under an unprotected atmosphere. After preprocessing the collected melt pool radiation signals, we examined the mapping relationships among process parameters, forming performance, and optical radiation signals intensity. Subsequently, signal processing techniques, such as fast Fourier transform (FFT) and wavelet transform, were employed to analyze the characteristic changes of the optical signals in the time-frequency domain. This study provides theoretical guidance for applying process monitoring in SLM.

Laser power has a direct effect on the time-domain mean of the optical signal, which in turn influences the mechanical properties and surface roughness of the formed parts. However, the scanning speed shows minimal impact on the mean value of the optical signal intensity. FFT and wavelet transform analyses revealed a strong relationship between the appearance and distribution of characteristic peaks and scanning speed. The study also shows that reducing input energy can improve the stability of the melt pool and significantly suppress the splashing phenomenon caused by the high-energy beam impact. This is particularly significant for improving both the surface and internal quality of SLM-formed parts.

(1) At low laser power, the surface melt of the sample is discontinuous, and an obvious spheroidization phenomenon occurs. As the laser power increases, the surface melt becomes continuous and complete. As scanning speed increases, the amount and size of residual splashes on the sample surface and powder bed gradually decrease, although this may lead to insufficient powder melting. When this occurs, the melt becomes discontinuous, cracks expand, and the density of the samples is significantly reduced. At lower scanning spacing, a severe oxidation reaction occurs during the forming process. Additionally, as scanning spacing increases, gaps form between each melt, and more pores and incomplete fusion defects appear.

(2) The amplitude variation of the time-domain signals is mainly influenced by laser power rather than scanning speed. As laser power increases, the amplitude of the optical signal increases, but its stability decreases. As scanning distance increases, the mean and standard deviation of the optical signal intensity initially increase and then decrease.

(3) When scanning speed is below 1000 mm/s, increasing the laser power leads to a decrease in surface roughness with an increase in the average optical signal intensity. As the optical signal intensity increases, the porosity of the sample decreases significantly. At optimal laser power, the surface roughness and porosity show a trend of initially decreasing and then increasing with the increase in scanning speed, while the average optical signal remains relatively stable. At different scanning spacing, surface roughness and porosity decrease as the amplitude of the optical signal increases. Meanwhile, the average density and signal intensity mean of each process group decrease with decreasing laser power. At the same scanning speed, the coefficient of variation also decreases with decreasing laser power. Increasing scanning spacing causes the density of the sample and the optical signal intensity mean to follow a trend of first increasing and then decreasing. The performance of the tensile samples increases with an increase in the mean radiation signal intensity of the melt pool.

(4) The frequency range of the optical signals is primarily concentrated in the low-frequency band. Additionally, spectral peaks in the low-frequency part distribute at certain intervals. The periodic signals exhibited in the spectrum are closely related to the generation of splashing. Based on wavelet transform, we find that the appearance and distribution of the characteristic peaks in the frequency domain signal of the melt pool are not significantly related to laser power, but are closely tied to scanning speed. Further analysis through three-layer wavelet packet decomposition reveals that the signal is mainly concentrated in the frequency range of 0‒12500 Hz. The kurtosis value of the time-domain signals decreases with increasing scanning speed. The splashing induced by high-energy beam impact is significantly suppressed as scanning speed increases.

.- Publication Date: Mar. 21, 2025

- Vol. 52, Issue 8, 0802304 (2025)

Austenitic stainless steel is widely utilized in modern manufacturing due to its excellent corrosion resistance and ease of processing. However, it exhibits relatively low deformation resistance and poor hardness as well as wear resistance. Inconel 718, an alloy with superior mechanical properties and excellent corrosion resistance, is employed in laser directional energy deposition (LDED) to enable additive manufacturing of dissimilar metals. To improve the connection process and quality of the two materials as well as expand the application of LDED for joining Inconel 718 alloy with 304 stainless steel, it is essential to investigate the influence of the laser deposition thermal cycle on the microstructure evolution of Inconel 718/304 connectors. This study also seeks to clarify the changes in mechanical properties resulting from the microstructure evolution.

304 stainless steel was selected as the substrate, and Inconel 718 alloy powder (particle size: 53?150 μm) was used as the cladding deposition material. The laser heat source was generated using an IPG-YLS-6000 fiber laser (maximum power: 6 kW, wavelength: 1070 nm, spot diameter: 3 mm), with a volume fraction of 99.99% argon as the shielding gas. A reciprocating layer-by-layer deposition process model was constructed using the KUKA industrial robot KRL programming system. The thermal cycle temperature of the deposited parts was dynamically monitored using an infrared pyrometer. Specimens were prepared via wire cutting, and their microstructure, composition, microhardness, and tensile property were analyzed using a scanning electron microscope, X-ray diffractometer, microhardness tester, and universal testing machine to explore the effects of thermal cycling temperature on the mechanical properties of the components.

Inconel 718/304 connectors were successfully fabricated using LDED technology, and their microstructure and mechanical properties were analyzed. The results revealed the following:

(1) Due to the heat accumulation effect, heat dissipation in the deposited part is reduced, leading to increased temperatures, decreased cooling rates, and gradual coarsening of Inconel 718 dendrites from the bottom to the top. Under the combined influence of the temperature gradient (G) and solidification rate (R), dendrites predominantly appear as columnar and cellular crystals.

(2) The Inconel 718/304 macro interface is clearly defined. Delta high-temperature ferrite precipitates on the austenite crystal surface in the interface remelting zone, and M23C6 secondary hard phase disperses in the heat-affected zone. The microhardness of each zone is as follows: Inconel 718 deposition layer > heat-affected zone > base metal. The average microhardness values of the above-mentioned areas are 283, 238, and 220 HV0.1, respectively.

(3) Due to precipitation carbide dispersion strengthening, the average yield strength of Inconel 718/304 parts is higher than that of hot-rolled 304 stainless steel parts, reaching 376.0 MPa. The tensile strengths of the two parts are similar, at 720.0 MPa and 716.7 MPa, respectively. The overall elongation of the Inconel 718/304 parts is 53.9%, and their fracture mode exhibits mixed characteristics.

The short-time laser deposition process effectively facilitates the connection of Inconel 718/304 dissimilar metals. By precipitating a small amount of M23C6 hard-strengthening phase, the tensile properties and microhardness of the connectors are significantly improved compared to 304 stainless steel components.

.- Publication Date: Mar. 19, 2025

- Vol. 52, Issue 8, 0802305 (2025)

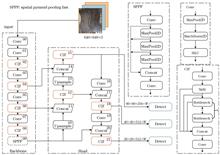

Magnesium alloy materials have broad application prospects in the fields of aerospace, automobile manufacturing, electronic communication, and biomedical treatment. Laser welding is one of the important means of achieving reliable connections between various structural parts made from magnesium alloys. During the laser welding process, the weld surface of the magnesium alloy is prone to spatter, weld bead, undercut, and collapse defects. The defect forms are complex and diverse and have varied sizes. Manual and traditional visual inspections of weld surfaces of magnesium alloys have problems such as low detection efficiency and high rates of missed and false detection, which seriously affect the service performance and life of the structural parts. The application of machine learning for defect detection has proven effective in offering effective solutions to the above problems. Focusing on the problems of reliance on a large amount of labeled data, low-quality pseudo-labels, and class imbalance in fully supervised and semi-supervised learning, the method of active semi-supervised learning for identifying surface defects in the laser welding of magnesium alloy is proposed in this paper by combining semi-supervised learning with active learning. It is expected that this method can effectively identify defects the premise that a certain level of accuracy can be ensured using limited labeled data, thereby improving the welding quality and reducing the production cost.

The proposed method of active semi-supervised learning incorporates an adaptive dynamic threshold adjustment module (ADTAM) and a sample selection mechanism (SSM). The confidence thresholds are adjusted dynamically, and the pseudo-label generation process based on the characteristics of different defect classes is optimized adaptively by ADTAM. The proposed method also incorporates regression loss from the region proposal network and the region of interest, as well as the intersection over union (IoU) thresholds, to address class imbalance and enhance pseudo-label quality. SSM analyzes the consistency between Teacher and Student model predictions, filtering high-quality pseudo-labels based on IoU and discarding low-confidence labels or incorporating them into the active sampling pipeline for annotation. Additionally, after semi-supervised training, entropy-based active sampling is employed to identify the most informative unlabeled samples for manual annotation. Subsequently, these samples are added to the training set to further enhance model generalization. To validate the effectiveness and universality of the proposed method, experiments are conducted on self-constructed magnesium alloy welding (MAW) and public NEU-DET datasets. The overall and class-specific detection accuracy and convergence of the loss function were included in the evaluations. The specific contributions of the modules were also analyzed by ablation studies.

The MAW and NEU-DET datasets contain 4418 and 1800 images, respectively. The respective numbers of images in the training and test sets were 3534 and 884 for the MAW and 1440 and 360 for the NEU-DET. Based on the ISO 5817—2014 standard, this study defined five defects: undercut, spatter, weld bead, collapse, and others. The average precision AP50 and mean average precision mAP50:95 were adopted as evaluation indicators for the recognition performance of the proposed method.

In the defect recognition experiments, (1) when the labeling ratio is 20%, the overall recognition accuracies of AP50 by the proposed method reach 86.32% and 78.11% for the MAW and NEU-DET datasets, respectively, which is a respective improvement of 11.19 and 10.07 percentage points compared to Faster R-CNN and 5.58 and 4.75 percentage points compared to Active Teacher. The corresponding accuracy values of mAP50:95 by the proposed method for the two datasets improve by 6.39 and 5.88 percentage points compared to Faster R-CNN and by 1.56 and 0.86 percentage points compared to Active Teacher. (2) The single-class recognition accuracies of mAP50:95 by the proposed method using the two datasets are superior to those of other methods. The accuracies for “Collapse” and “Patches” by the proposed method for the MAW and NEU-DET datasets are the highest, with a respective improvement of 7.31 and 11.61 percentage points compared to Faster R-CNN and 1.69 and 0.74 percentage points compared to Active Teacher. (3) The loss values of the proposed method converge to 0.51 and 0.09 for the MAW and NEU-DET datasets, respectively, which is a decrease of 0.12 and 0.09 compared to Unbiased Teacher/Active Teacher and 0.65 and 0.45 compared to Soft Teacher.

In the ablation experiments, (1) the key modules of ADTAM, SSM, and the active sampling strategy play a positive role in improving recognition accuracy. The respective contributions of the modules are 3.01, 2.92, and 2.08 percentage points (AP50) and 0.78, 1.24, and 0.31 percentage points (mAP50:95) for the MAW dataset, and 1.25, 3.46, and 1.73 percentage points (AP50) and 0.28, 0.91, and 0.45 percentage points (mAP50:95) for the NEU-DET dataset. (2) In terms of the hyperparameter settings, the values of AP50 and mAP50:95 first increase and then decrease as the threshold ε and adjustment coefficient η increase, and they reach their optimum values at ε=0.8 and η=0.010.

In the defect visualization experiments, the proposed method can accurately identify tiny defects compared to other methods. It can capture detailed information at different scales, avoid mislabeling in nondefective areas, and ensure a higher recognition accuracy and a lower false detection rate. It also shows potential in defect recognition of complex textures, tiny areas, and edges of the weld surface.

Experiments on defect recognition, ablation, and visualization were performed using the self-constructed MAW and public NEU-DET datasets to evaluate the performance of the proposed method against traditional fully supervised and semi-supervised methods. The experimental results show that for small-sample, multiscale, and complex morphological defects on the surface of magnesium alloy welds, the proposed active semi-supervised learning method significantly reduces the amount of data annotation and achieves varying degrees of improvement in recognition accuracy (AP50 and mAP50:95) compared with other methods. This shows that the proposed method has the ability of effective identification, lower rates of false and missed detection, and better robustness and versatility. The research has important theoretical and engineering application potential for realizing low-cost, high-efficiency, and high-quality welding of magnesium alloy structural parts and for improving their service performance and life.

.- Publication Date: Mar. 19, 2025

- Vol. 52, Issue 8, 0802103 (2025)

Defects such as cracks, porosity, pits, undercuts, and slag inclusions commonly occur in laser welding and gas-shielded welding processes. However, imaging these defects poses a challenge, which has led to a scarcity of samples and an imbalance in the frequencies of different types of defects. Recent deep learning algorithms often have high complexity, a large number of parameters, and high consumption of computational resources. To address these challenges, this study aims to solve problems such as the scarcity of defect images, any imbalance in the data that affects detection accuracy, high model complexity that hinders real-time detection, and difficulty with the recognition of small features. Data augmentation techniques were applied to the dataset to increase the amount of data and balance the sample defect types. Simultaneously, an improved YOLOv8 model, named YOLO-DEFW, was proposed to reduce the number of parameters needed, increase detection speed, and improve detection accuracy for small defects and those for which there were only a few samples, which enables the intelligent visual inspection system for welds to perform real-time detection tasks online.

In the experiment, the ROBOT_WELD weld defect dataset was compiled and used as the training set for the YOLO-DEFW model. First, images were captured by the MV-HS2000GC camera mounted on a robotic arm, and additional samples were sourced from public datasets. Subsequently, the dataset was increased in size from 460 to 11960 images using 25 techniques for image augmentation. The optimized YOLO-DEFW model was characterized by the following improvements: DSConv2D was used in place of the standard convolution layers (Conv) at layers 0, 1, 3, 5, 7, 17, and 21, and C2f_DSConv2D was used to replace C2f at layers 2, 4, 6, 8, 12, 15, 19, and 23, which reduced the number of model parameters; EMA module was introduced into layers 16, 20, and 24 to enhance the model's ability to recognize weld defects in features of varying sizes; and the composite loss function FWCE Loss was added to the loss.py file, where the weight parameters were adjusted for Focal Loss and Weighted Cross Entropy (WCE) Loss to improve accuracy in detecting small-sample weld defects.

The development of the ROBOT_WELD dataset and data augmentation effectively increased the size of the dataset to 11960 images, thereby enhancing the model’s generalizability. By running ablation experiments with common convolution modules, DSConv2D was identified to be the most effective module for reducing the parameter count, where the lowest parameter count was 32 and lowest GFLOPs was 0.0003 (see Table 3). Different attention mechanisms were also introduced to improve the recognition of small features, and EMA module yielded the best overall performance (see Table 4). Additionally, introducing the customized FWCE Loss improved the detection accuracy for small-sample defects. The improvements to YOLOv8 resulted in a 13.4% increase in precision, a 17% increase in recall, and a 24.8% increase in mean average precision (mAP) on the ROBOT_WELD test set. Model complexity was also reduced: the number of parameters was reduced by 13.5%, GFLOPs were reduced by 10%, and the single image processing time was 3.9 ms, which resulted in a 12% increase in the accuracy of small-feature recognition. The improved YOLO-DEFW model outperformed the YOLOv8 model on key performance metrics.

This study expanded the original dataset using 25 data augmentation techniques, which increased the size of the dataset by 25-fold and effectively enhanced the robustness and generalizability of the model. The proposed YOLO-DEFW model utilizes DSConv2D instead of Conv in YOLOv8, significantly reducing its parameter count and computational load. The introduction of an EMA module effectively captures features at varying scales within the images, thereby significantly improving the accuracy of the model in detecting small features. Furthermore, the model incorporates a composite loss function (FWCE Loss) and adjusts the weight parameters of Focal Loss and WCE to effectively improve its detection on minority categories and imbalanced samples. The YOLO-DEFW model achieves notable optimization in terms of parameter count, model complexity, and detection accuracy; in the present study, the primary evaluation metrics improved by more than 10%. This algorithm can be integrated into the vision sensors of intelligent welding robots and used for real-time defect detection online, in low-arc-noise welding processes, and in high-arc-noise post-weld inspections, which will pave the way for advances in intelligent welding inspection technology.

.- Publication Date: Mar. 17, 2025

- Vol. 52, Issue 8, 0802105 (2025)

This study investigates the laser welding of 1.4 mm thick hot-stamped steel with Al?Si coating using nickel-based alloy filler metal. The microstructural differences in the weld joint under varying laser powers and feeding rates are systematically compared and analyzed. Additionally, the influence of alloying elements on the performance of the joints is thoroughly explored. The results demonstrate that Ni and Co, as strong austenite-stabilizing elements in the nickel-based filler metal, effectively mitigate the adverse effects of aluminum (Al), preventing peritectic transformation and the formation of ferrite in the weld. When the mass fraction of Ni in the weld exceeds 3.8%, the segregation of the Al element is entirely suppressed, and the weld exhibits a fully martensitic structure before and after hot stamping. Furthermore, when the mass fraction of Ni in the weld is 6.47%, second-phase particles, such as M23C6 and TiN precipitates, are observed in the martensitic matrix, further enhancing the strength of the weld. The optimal welding joint exhibits an average hardness of 535 HV and a tensile strength of 1643.5 MPa, comparable to the base metal. The joint is broken at the base metal.

The current research primarily focuses on using metal foil filling technology with a single alloying element to improve the laser welded joint strength of hot-stamped steel with Al?Si coating. However, the application of Ni foil filling technology is limited in its application scope in industrial production due to the complexity of the process and the uncontrollable content of introduced Ni. In view of this, this study proposes the use of nickel-based alloy welding wires for laser welding. By adjusting laser power and wire feeding speed, the alloy element content in the weld metal can be controlled effectively.

From Figs. 2(d)?(f), it is evident that increasing the laser power further increases the amount of filler metal melted, resulting in a significant reduction of δ-ferrite within the weld seam of sample 2#, with only a small amount of small-sized particles present near the surface and fusion line. In sample 3#, an increased feeding speed leads to a higher Ni content in the weld seam. Figure 2 (g)?(i) shows that the weld seam of sample 3# exhibits a nearly fully martensitic structure, representing a significant improvement compared with that of samples 1# and 2#. Figure 3 displays the microstructure of the weld seam after laser welding and hot forming using nickel-based filler metal. From Figs. 3(a)?(c), it is clear that after hot forming, the weld seam of sample 1# transitions from the original δ ferrite to a mixed structure of martensite and α ferrite, with ferrite mass fraction around 18%. Figure 8 presents the tensile properties and fracture locations of the weld joints (1#, 2#, and 3#) using nickel filler metal. The tensile curves reveal that the tensile strengths of all three groups are over 1630 MPa, comparable to the strength level of the base material. The curves for all specimens show significant plastic deformation, indicating a considerable improvement in tensile properties.

The use of nickel-based alloy welding wires significantly improves the microstructure of weld seams. When the mass fraction of Ni in the weld exceeds 3.8%, aluminum segregation is effectively suppressed, resulting in a fully martensitic structure both before and after hot forming. With the mass fraction of Ni increases to 6.47%, second-phase particles such as M23C6 and TiN precipitate in the weld, with solid solution strengthening effects significantly enhancing the mechanical properties of the joint. Additionally, austenite-stabilizing elements such as Ni and Co suppress the adverse effects of aluminum on the austenite phase, ensuring the complete peritectic transformation and suppressing δ ferrite formation. The optimal welding joint (sample 3#) welded with nickel-based wire exhibits excellent mechanical properties. The average hardness of the weld area reached 535 HV, and the tensile strength was up to 1643.5 MPa, comparable to the base metal. Furthermore, the fracture occurring on the base metal side indicates improved ductility of the welded joint. The uniform distribution of alloying elements such as Ni, Co, and Cr within the weld plays a critical role in enhancing the joint’s performance. Ni enhances weld strength by lowering the austenite transformation temperature and expanding the austenite phase field. The synergistic effects of Co and Cr further promote structural uniformity and optimal second-phase distribution. These elements significantly improve the mechanical properties of the weld joint through mechanisms such as solid solution strengthening and grain refinement.

.- Publication Date: Mar. 17, 2025

- Vol. 52, Issue 8, 0802107 (2025)

Semantic segmentation algorithms based on deep learning can segment an image of the molten pool generated by the laser welding process. The results of an analysis of this molten pool can be used to adjust the welding parameters in real time, thereby improving the quality of laser welding. Although it is desirable to use a simple neural network to extract the complete molten pool, the existence of the wire, arc, spatter, smoke, and other sources of interferences often make the welding environment very complex. Thus, it is very difficult to extract the complete molten pool and detect it using a simple neural network. This study addresses the problems with the welding process. The use of denoising and tracking networks are proposed for a molten pool enhancement method, along with the use of a semantic segmentation network based on a Mask2Former lightweight improvement to accurately segment a molten pool image.

This study analyzes the noise in a molten pool image from a dataset. The causes and types of noise in molten pool images vary and a clear image of the molten pool may be lacking. Therefore, SCUNet is adopted to realize the blind denoising of a molten pool image. The molten pool is the smallest target in the image. Therefore, in order to reduce the interference from the useless parts of the image and improve the detection efficiency, we utilize MixFormer to track and localize the molten pool during the welding process. In order to meet the demand for the real-time detection of the molten pool, the Mask2Former semantic segmentation network is lightened and improved, and MobileNetV3 is used instead of the original backbone network. Then, ResNet101 is used as the backbone of the Mask2Former network as a teacher network to distill the knowledge of the lightened network, allowing the accurate segmentation of the molten pool image.

An evaluation of the denoising network index and the denoising results show that the algorithm reported in this paper can significantly reduce the interference caused by the arc light during the laser welding process compared with other algorithms. Thus, the changes in the molten pool image are smoothed, and the molten pool pattern is clear (Table 1 and Fig. 7). A comparison shows that MixFormer is better able to balance the tracking accuracy and speed compared to other networks (Table 2 and Fig. 8). A performance evaluation of the backbone network using a test set shows that the detection accuracy of the MobileNetV3 model is slightly lower than that of the other selected models, but its number of parameters and computation amount are 0.93×106 and 0.32×109, respectively, which are smaller than the numbers for the other selected networks. Its MIOU can reach 97.02%, which shows that MobileNetV3 can ensure the feature extraction ability of the network while keeping the number of parameters and computation amount small. This indicates that MobileNetV3 ensures the feature extraction ability of the network while keeping the number of parameters and computation volume small (Table 3). The results of an experimental analysis of the effect of temperature on distillation show that when the temperature is set to five, the IOU and MIOU reach their maximum values, indicating that the network has the best distillation effect (Table 4). The inference time of the method proposed in this paper is 84.7 ms, and the MIOU is 97.21%, indicating that the distilled model can better balance the accuracy and real-time performance, and has good detection performance (Table 6 and Fig. 14)

This paper reports how the molten pool generated by the laser welding process was used as an experimental object. Using the reported method, the image of the laser welding molten pool is blindly denoised by SCUNet, and then the molten pool is tracked using the single-target tracking algorithm. Finally, the molten pool is segmented using Mask2Former. The weight of the segmentation network is lightened using the knowledge-distillation method. Thus, MobileNetV3 can dynamically segment a molten pool through knowledge distillation by learning the knowledge of the teacher network. The experimental results show that (1) the peak signal-to-noise ratio and structural similarity of 37.87 dB and 0.95, respectively, are better than those of a traditional denoising algorithm when SCUNet is used for denoising the molten pool image, indicating that this algorithm can realize the denoising of an image under the guarantee of image similarity. (2) The MixFormer algorithm is used to track the molten pool. Compared with STARK and SiamRPN++, it achieves better results in realizing molten pool tracking. (3) Compared with the classical semantic segmentation model, the MIOU and detection speed of the lightweight molten pool detection method based on the improved Mask2Former are 94.21% and 84.7 ms, respectively, which allow it to quickly and accurately detect the molten pool. The smaller number of parameters for the backbone network is more favorable for real-time detection and deployment, which shows the superiority of the method reported in this paper in the detection of the molten pool produced by laser welding.

.- Publication Date: Mar. 17, 2025

- Vol. 52, Issue 8, 0802108 (2025)

The rapid advancement of ultrafast laser technology has opened new avenues for precision manufacturing, particularly in fabricating microstructures on hard and brittle materials, such as glass. However, achieving high-quality microstructure fabrication on such materials remains challenging owing to their inherent properties, including high hardness and brittleness. Therefore, this study aims to investigate and optimize the methods for ultrafast laser microstructuring of hard and brittle materials, focusing on the influence of laser power on crack formation, propagation, and processing efficiency. We propose a gradient power processing strategy to enhance machining quality while maintaining processing efficiency. The importance of this study lies in its potential to mitigate issues related to crack generation and propagation during ultrafast laser processing of hard and brittle materials, thereby enhancing quality and efficiency. Furthermore, the findings can expand the application of microstructures on hard and brittle materials in advanced technological fields.

A femtosecond laser with a wavelength of 1030 nm, pulse duration of 900 fs, and Gaussian beam profile was employed herein. Microholes arrays were processed in quartz glass (0.15 mm thick) at a constant pulse frequency of 10 kHz and an average scanning speed of 0.1 m/s. The experimental procedure involved initially investigating the generation and propagation mechanisms of cracks during machining. Subsequently, the processing effects of varying laser power on quartz glass were compared to analyze the relation between processing power, crack formation, and processing efficiency. Based on these analyses, a gradient power processing strategy was proposed. In-situ temperature measurements were taken during processing to validate the effectiveness of the proposed strategy in reducing the temperature gradient and minimizing thermal stress generation.

1. During ultrafast laser processing of quartz glass, crack propagation can be divided into four stages: a) solidification of the melt at the bottom of the hole creates microcracks, b) these cracks propagate outward through the hole wall, c) the outward-propagating cracks form annular cracks around the hole, and d) the connection of multiple annular cracks within the microhole array leads to processing failure (Fig. 2).

2. Comparative analysis of the impact of different laser powers on machining effects reveals that low-power processing effectively reduces recast layer formation and thermal stress generation but decreases processing efficiency (Fig. 3). Therefore, a gradient power processing strategy is proposed to optimize processing quality while maintaining efficiency. The effects of different gradient power strategies on machining surface quality and efficiency are explored. The results show that a lower and gradual power gradient yields better processing outcomes. This is attributed to the smooth transition of power from low to high, leading to a gradual temperature increase, thereby avoiding notable temperature gradients. This effectively suppresses crack formation and propagation, thus achieving an optimized balance between efficiency and quality (Fig. 4).

3. In-situ temperature measurements are used to compare temperature variations during microhole array processing of quartz glass under constant and gradient power conditions. The results indicate that gradient power processing reduces the maximum temperature in the initial processing stage and lowers the temperature at each power level, allowing the processing temperature to stabilize quickly (Fig. 5).

4. The crack suppression mechanism of gradient power processing includes the following: in the initial stage, low-power processing increases surface roughness, enhancing laser absorption and promoting heat dissipation through phase transition in subsequent stages, thereby reducing thermal stress. With increasing power, the hole depth has already developed to a certain extent, resulting in a reduced stress concentration at the hole wall. This reduces crack propagation along the hole wall and blocks the crack path (Fig. 6).

This study investigates the mechanisms of crack initiation and propagation during microhole array fabrication on quartz glass using 900 fs laser pulse and demonstrates the effective suppression of crack formation and expansion through a gradient power dynamic regulation strategy. The findings reveal that crack formation and propagation occur in four stages and that adopting a “low-power-to-high-power” gradient power processing strategy can suppress crack propagation without compromising processing efficiency. In-situ temperature measurements indicate that gradient power processing considerably reduces the maximum temperature difference, enhancing fabrication process stability. Furthermore, the crack suppression mechanism of gradient power processing involves the initial low-power phase that increases surface roughness to enhance laser absorption, reduce internal thermal stress, and allow the hole depth to reach a critical level. Transitioning to high-power processing subsequently prevents crack propagation from the bottom of the hole to the sidewalls. The proposed gradient power processing strategy is broadly applicable to laser micromachining of hard and brittle materials and holds considerable potential for various applications.

.- Publication Date: Mar. 19, 2025

- Vol. 52, Issue 8, 0802406 (2025)

Hydrogels are a class of polymeric soft materials with a three-dimensional (3D) crosslinked hydrophilic network structure, which possess the softness and high water content of natural tissues. They offer advantages over other synthetic biomaterials in simulating natural living tissues. In conventional approaches, ultraviolet (UV)-band single-photon beams are used for mode transitions in hydrogels.

However, these approaches often fall short in terms of penetration depth and resolution, failing to meet the experimental expectations. In emerging methods, two-photon excitation of hydrogel materials using ultrafast lasers in the near-infrared band can improve the spatial and temporal resolution of hydrogels in various response states. However, these methods provide only single results for hydrogels and lack of multimodal processing capabilities, thereby limiting the application scenarios for hydrogels. In this study, we combine femtosecond laser direct-write micro/nano-processing with multiple optical response states of hydrogels. We propose a multimodal processing method for hydrogel materials that realizes the bimodal processing of laser additive?removal for the same hydrogel. This processing scheme can create more diverse hydrogel environments through multimodal manipulation of different states of same hydrogel material, offering considerable potential for applications in simulating various biological tissue constructions and in vitro cell culture.

In this study, a femtosecond laser system with an 800 nm wavelength, 100 fs pulse width, and 80 MHz repetition frequency was used. The laser spot diameter ranged from 1 to 2 μm. This system used multiphoton effects to induce photopolymerization and photoablation in a gelatin methacrylate (GelMA) hydrogel, thereby enabling polymerization and the removal of custom channels during the formation of 3D structures. During the laser addition process, methacrylic anhydride was first introduced into the hydrogel precursor mixture to facilitate light curing. A femtosecond laser was focused within the GelMA hydrogel pre-fluid, triggering photopolymerization. The monomer molecules absorbed two photons, forming multichain polymers. For the laser removal process, the GelMA hydrogel was first cured using UV light. In particular, the femtosecond laser’s high energy density induced photochemical and photothermal reactions in the hydrogel. By optimizing the processing parameters, we controlled the temperature and pressure in the ablation region, generating cavitation bubbles. These bubbles expelled the waste material produced during photoablation and ultimately allowed the creation of the desired microchannel structures.

Results demonstrate that by fine-tuning key parameters, such as laser energy density, spot dwell time, and scanning mode, the photopolymerization and photoablation processes can be precisely controlled. These adjustments have minimal interference with the surrounding environment. As shown in Fig. 3, the GelMA hydrogels formed via femtosecond laser direct-write polymerization have high resolution and cleanliness. This allows for the precise formation of customized 3D structures. By adjusting the crosslink spacing, we can obtain different crosslinking patterns, such as row-resolved crosslinking with high separation, surface-resolved crosslinking with medium aggregation, and smooth-body crosslinking with high aggregation. These different crosslinking arrangements provide flexibility in designing the mechanical properties and spatial organization of the materials. Figure 5 illustrates the successful fabrication of the microchannel structures removed by the laser from a GelMA hydrogel sample that has undergone UV crosslinking curing. These microchannels vary in length, diameter, and shape, illustrating the ability of femtosecond laser processing techniques to enable highly accurate and versatile channel designs. The successful fabrication of the complex customized structures further highlights the broad applicability and potential of this approach.

In this study, we proposed an innovative femtosecond laser-based multimodal processing scheme for the microscale and nanoscale processing of hydrogels. The proposed scheme is highly designable and precise. By modifying the existing mixture of photosensitive hydrogel precursors and photoinitiators, we created a hydrogel processing pre-fluid with a light-curing property. By changing a series of parameters, such as femtosecond laser power, spot residence time, and scanning mode, photocrosslinking additive and photoablation removal modes can be effectively implemented using the proposed femtosecond laser processing scheme. Through careful control of dwell time and scanning line spacing, it is possible to fabricate row-resolved crosslinked, surface-resolved crosslinked, and smooth-body crosslinked hydrogel structures with minimal disturbance to the surrounding material. By integrating computer programs for processing customized structures and exporting processing files, laser additive manufacturing of various 3D structures can be achieved, enhancing fabrication precision. The photoablation removal experiments can also be performed on the hydrogel precured with UV light by flexibly adjusting the laser power and scanning times of the femtosecond laser. The resulting microchannels show excellent adjustability and flexibility in the dimensions of length, diameter, and shape. In summary, the proposed method achieves multimodal processing of a hydrogel and customizes the target structure of the hydrogel under the action of light, opening up considerable possibilities for applications in in vitro cell culture, tissue simulation, and other cutting-edge biomedical fields.

.- Publication Date: Mar. 20, 2025

- Vol. 52, Issue 8, 0802408 (2025)

H13 steel (4Cr5MoSiVl), a hot-working die steel, exhibits excellent wear resistance, hardness, and heat fatigue resistance. It is a crucial material for manufacturing hot extrusion and die-casting molds, which operate under high-temperature conditions and are subject to wear, corrosion, and other failure modes. These can lead to premature failure, reduced service life, significant economic losses, and resource wastage. Therefore, extending the service life of molds by repairing damaged sections, restoring geometry, and ensuring mechanical properties that are comparable to or exceed those of new molds is highly significant. The quality of the cladding layer (including geometric dimensions, dilution rate, macroscopic defects, and mechanical properties) depends not only on the matrix material and cladding powder but also on process parameters such as laser power, scanning speed, and powder feed rate. Excessive laser power may induce high residual stress, leading to cracks in the cladding layer, while insufficient laser power results in inadequate matrix melting and poor bonding strength between the matrix and cladding layer. Identifying the optimal combination of process parameters is, therefore, critical to achieving high-quality cladding layers. However, most existing studies utilize circular light spots, and fewer studies focus on large-size rectangular light spots due to challenges in their energy distribution. Circular spots typically require multi-pass overlapping cladding due to their limited irradiation size. Rectangular broadband spots, on the other hand, enhance cladding efficiency and allow for investigations into the impact of overlap rate on surface flatness under different conditions.

The matrix material used is H13 steel, and the powder material is H13 powder, ensuring minimal thermal and physical property differences to avoid cracking of the cladding layer. Laser power, scanning speed, powder feed rate, and overlap rate are considered as inputs in a four-factor and four-level orthogonal test design for cladding H13 powder onto the H13 substrate. Cladding specimens are sectioned using wire cutting and sequentially polished with sandpapers. The sections are corroded using a nitrate alcohol solution for microscopic analysis. Cross-sectional images are captured using an optical microscope, and ImageJ software is used for data measurement. To characterize the geometric morphology of the cladding layer along the scanning velocity direction, three cross-sections are measured, and average geometric parameters of the cladding layer are calculated. The influence of process parameters on the geometry of the cladding layer is analyzed, with cladding width (W), flatness (τ), and dilution rate (η) selected as output response values.Grey correlation analysis (GRA), technique for order preference by similarity to ideal solution (TOPSIS), and rank-sum ratio (RSR), combined with the entropy weight method (EWM), are employed to evaluate and compare the response values. The longitudinal and transverse microhardness of the optimized cladding layer are measured using a microhardness tester. Additionally, the cross-sectional microstructure is observed using a scanning electron microscope (SEM), while element distribution is analyzed using the SEM's energy dispersive spectrometer to determine the reasons for the increased hardness.

Through the orthogonal test design, it is determined that different process parameters have varying effects on the geometric morphology of single-layer multi-pass cladding (Table 2, Fig. 3). The macroscopic morphology is analyzed in detail, and variance analysis is conducted to assess the influence of rectangular laser spot parameters on the geometric morphology of the cladding layer and its variation trends (Tables 3, 4). Using W, τ, and η as response values, the GRA, TOPSIS, and RSR methods, combined with the EWM, provide multi-objective comprehensive evaluations. The optimal parameter combinations under each method are identified (Fig. 6), and the specimens' comprehensive performance is improved under all three combinations (Tables 7, 8, 9). Experimental comparisons show that the error between the predicted comprehensive evaluation coefficient (0.819) and the actual value (0.871) using the GRA-EWM method is only 6.0%. The average microhardness of the cladding layer (867.6 HV0.3) is found to be 4.01 times higher than that of the matrix (216.2 HV0.3) (Figs. 7).

Variance analysis reveals that cladding width (W) is primarily influenced by the overlap rate. The scanning speed has the most significant impact on the height (H) of the cladding layer and the cladding layer area (Sc). For the molten pool area (Sm), laser power exerts the greatest influence. Furthermore, flatness (τ) is most affected by the overlap rate and shows a negative correlation with it. Laser power, scanning speed, powder feed rate, and overlap rate significantly affect the dilution rate (η), with η positively correlated with laser power and scanning speed but negatively correlated with powder feed rate and overlap rate. From the perspective of improving the accuracy of comprehensive evaluation or minimizing errors, the GRA-EWM method is notably effective, with an error of only 6.0% between predicted and experimental values. This method outperforms the TOPSIS-EWM and RSR-EWM methods in accuracy and yields cladding specimens with superior hardness improvements, aligning with the repair objectives.

.- Publication Date: Mar. 17, 2025

- Vol. 52, Issue 8, 0802201 (2025)

Cr12MoV cold work die steel is widely used in the roll industry owing to its advantages such as low deformation, high abrasion resistance, and large bearing capacity. However, Cr12MoV rolls exhibit high hardness and brittleness, making them prone to spalling, pitting, cracking, and other microarea damage under service conditions. The harsh operational environment of rolls often involves substantial impact, extrusion, and external friction, leading to localized damage such as large-area spalling and cracking, ultimately resulting in roll scrap. Laser repair is a key method for restoring damaged rolls. This technique enables the formation of dense microstructures and metallurgical bonds at the interface, making it an important technology for repairing damaged Cr12MoV rolls. However, the surface hardness of the repaired layer exhibits fluctuations under the conventional laser mode, particularly in the interfacial transition zone. These variations negatively affect the rolling accuracy of high-precision plates and shorten the service life of rolls. This study explores the application of swing laser beams in welding to promote the transformation of columnar crystals to equiaxed crystals, addressing issues related to non-uniform surface hardness in repaired Cr12MoV rolls. This method aims to minimize hardness fluctuations in the interfacial transition zone, reduce metallurgical defects, and establish a framework for high-quality surface repair of Cr12MoV rolls.

The surface of a Cr12MoV roll was machined into a trapezoidal damage repair groove using fine engraving technology. The damaged area was then repaired at conventional laser and figure-8 swing laser modes. The following steps were undertaken: 1) comparing the repair layer molding quality at two laser modes; 2) analyzing and comparing the microstructure of the cross-section at the same depth of the repair layer using metallographic microscopy; 3) analyzing and comparing the phase composition of the repair layer via X-ray diffraction; 4) examining the distribution of main elements (Fe and Cr) in the repair layer via energy-dispersive spectroscopy line scanning; 5) testing the microhardness and wear resistance of the repair layer at different laser modes. By combining microstructural analysis, elemental distribution, and other findings, this study explored the mechanism through which the figure-8 swing laser influences the surface microhardness uniformity of the repair layer.

At conventional laser mode, the surface color of the repair layer is dull, and cracks are observed in the interface bonding zone (Fig. 7). The microstructure comprises a mixture of coarse columnar dendrites and equiaxed dendrites (Fig. 8, Fig. 9, and Fig. 10). The difference between the maximum and minimum surface microhardness values is 185.0 HV, with a microhardness fluctuation coefficient of 35.8 (Fig. 13). Large spalling pits are found in the repair layer after friction and wear tests (Fig. 16 and Fig. 17). Furthermore, the figure-8 swing laser considerably improves the appearance of the repair layer, imparting a metallic luster to the surface and eliminating cracks in the interface bonding zone (Fig. 7). The figure-8 swing increases convection in the molten pool, interrupts the growth of columnar dendrites, and transforms the microstructure into a uniform pattern of fine equiaxed dendrites (Fig. 8, Fig. 9, and Fig. 10). The difference between the maximum and minimum surface microhardness values is 61.1 HV, with the microhardness fluctuation coefficient reducing to 13.2 (Fig. 13). Surface microhardness uniformity is improved considerably, while the friction coefficient decreases from 0.66 to 0.56. In addition, the width and depth of the wear marks decrease considerably (Fig. 16 and Fig. 17).

The study compared the effects of conventional laser and figure-8 swing laser modes on the repair layer and found that the figure-8 swing laser substantially can enhance the morphology and quality of the repair layer. The surface displays a metallic luster, and cracks in the interface bonding zone are eliminated, resulting in a smooth and defect-free repair layer. Additionally, Fe and Cr are more uniformly distributed in the repair layer. Furthermore, the figure-8 swing laser reduces the temperature gradient and improves the solidification rate. These factors provide a stable grain growth environment, collectively promoting the transformation of columnar dendrites into equiaxed dendrites and reducing structural heterogeneity in the repair layer. The microhardness uniformity of the repair layer is improved, and as a result, the width and depth of the abrasion marks decrease considerably. These changes lead to an increase in wear resistance.

.- Publication Date: Mar. 17, 2025

- Vol. 52, Issue 8, 0802203 (2025)

Laser cladding, a new type of surface strengthening and repair technology, has been widely used in the automobile and aerospace fields for parts repair. Owing to the limitations of the laser spot size and robot travel range, meeting the industrial production needs of large-area surface modification and remanufacturing is challenging for single-pass cladding. During multipass cladding, a high-energy-density laser beam induces the secondary melting and solidification of alloy powder and the substrate surface coating. This process alters heat conduction and the melt flow mode inside a molten pool, resulting in an instantaneous and complex dynamic evolution of the molten pool. Numerical simulation can deeply analyze such complex phenomena inside a molten pool, offering better insights into the influence mechanism of the melt flow and temperature distribution on the molding and quality of the cladding layer. In this study, we simulated the multipass cladding process, revealed the evolution of the temperature and flow fields, studied the influence of the overlap ratio on cladding layer flatness, and observed the morphology and microstructure of the cladding layer under the optimal overlap ratio through experimental methods. The results of this study will provide a valuable reference for analyzing the evolution law of the temperature and flow fields of a multipass molten pool through numerical simulation and determining the appropriate multipass cladding process parameters.

Considering the temperature and laser attenuation coefficient of the cladding powder, and the Gaussian distribution powder equation, a multiphase flow model of multipass laser cladding was established via numerical simulation. First, the evolution of the internal temperature and flow fields within a molten pool during the multipass cladding process was analyzed. Second, numerical models for multipass cladding under different overlap ratios of 25%‒60% were established to study the effects of the overlap ratio on the internal flow field of multipass molten pools, and the surface flatness values of the cladding layer under different overlap ratios were obtained; moreover, the overlap ratio yielding a highly flat cladding layer surface was determined. Finally, the laser cladding experiment on a 42CrMo substrate was performed under the optimal overlap ratio, and the microstructure of the cladding layer was observed.

In the first cladding pass, the temperature gradient distribution of a molten pool exhibits characteristics of high in the middle and low on both sides. During subsequent laser cladding, this gradient gradually flattens as the number of cladding passes increases (Fig. 6). Owing to the preheating effect from previous cladding passes, initial temperatures at three observation points gradually increase with each additional cladding sequence. In addition, the secondary peaks in the temperature curves at observation points D and E align with the peak temperature of subsequent measurement points. These peaks exceed the liquidus temperature of the cladding powder, indicating remelting at these points. This remelting causes the previous cladding layer to re-form into a molten pool (Fig. 9). During the first cladding pass, two stable and symmetrical counterclockwise swirls form within a molten pool under the combined action of Marangoni forces and buoyancy. In subsequent cladding passes, the lapped section of the cladding layers remelts into a molten pool. Such molten pools take on an obliquely elliptical shape, generating a gravitational component to the unlapped side, breaking the original force balance, and affecting the flow field motion law dominated by Marangoni forces. And thus the two internal swirls gradually become asymmetrical. This phenomenon becomes more pronounced as the number of cladding passes increases, resulting in changes to the microstructure and uneven topography of the cladding layer (Fig. 11). The flatness of the cladding layer first increases and then decreases as the overlap ratio increases. Flatness reaches its maximum value at a 40% overlap ratio (Table 4). At an overlap ratio of 35%, two swirls of different sizes form within a molten pool. At an overlap ratio of 45%, the overall height of the cladding layer increases, and surface tension on the overlap side is almost balanced by gravity. Consequently, only one swirl remains in the molten pool; furthermore, maintaining uniform melt flow is difficult and thus considerably decreases cladding layer flatness (Fig. 13). At an overlap ratio of 40%, the microstructure of the cladding layer transitions from planar crystals at the bottom to columnar, cellular, and equiaxed crystals toward the top. The crystal distribution is relatively uniform, and the distribution of dendrite is consistent with the simulation results (Fig. 15).

The temperature gradient of single-pass cladding shows a pattern of high in the middle and low on both sides under the Marangoni flow effect. In multipass cladding, this gradient gradually flattens with increasing the number of cladding passes. The initial and peak temperatures of the cladding layer rise with each successive pass, and when the temperature in the subsequent cladding process exceeds the liquidus temperature, remelting of the previous cladding layer occurs. In single-pass cladding, two symmetrical swirls form within a molten pool flow field under the action of Marangoni forces, which guide a melt to exhibit a cyclic flow. As the overlap ratio increases, the influence of gravity on the flow field of the molten pool increases, eventually causing the swirl on the lap side to disappear. This phenomenon changes the microstructure and causes the uneven surface morphology of the cladding layer. In addition, with the increase in the overlap ratio, the flatness of the cladding layer shows a trend of first increasing and then decreasing, and the optimal flatness value is observed at a 40% overlap ratio. Experimental results confirm that at this overlap ratio, the cladding layer exhibits a relatively flat surface with relatively uniform microstructure distribution.

.- Publication Date: Mar. 21, 2025

- Vol. 52, Issue 8, 0802204 (2025)