[1] J L STOLLERY. Hypersonic viscous interaction on curved surfaces. Journal of Fluid Mechanics, 43, 497(1970).

[2] M M OPEKA, I G TALMY, J ZAYKOSKI. Oxidation-based materials selection for 2000 ℃+hypersonic aerosurfaces: theoretical considerations and historical experience. Journal of Materials Science.

[3] G P SUTTON, O BIBLARZ. Inc., 2016: 540.

[4] D L SCHMIDT. Ablative polymers in aerospace technology. Journal of Macromolecular Science—Chemistry, 3, 327(1969).

[5] D SCITI, L ZOLI, L SILVESTRONI et al. Design, fabrication and high velocity oxy-fuel torch tests of a Cf-ZrB2-fiber nozzle to evaluate its potential in rocket motors. Materials & Design, 109: 709(2016).

[6] I LIFANOV, A YURISHCHEVA, A ASTAPOV. High-temperature protective coatings on carbon composites. Russian Engineering Research, 39: 804(2019).

[7] H I YOO, H S KIM, B G HONG et al. Hafnium carbide protective layer coatings on carbon/carbon composites deposited with a vacuum plasma spray coating method. Journal of the European Ceramic Society, 36, 1581(2016).

[8] A ABDOLLAHI, N EHSANI, Z VALEFI. High temperature ablation-oxidation performance of SiC nanowhisker toughened- SiC/ZrB2-SiC ultra-high temperature multilayer coatings under supersonic flame. Journal of Alloys and Compounds, 745: 798(2018).

[9] X JIN, X FAN, C LU et al. Advances in oxidation and ablation resistance of high and ultra-high temperature ceramics modified or coated carbon/carbon composites. Journal of the European Ceramic Society, 38, 1(2018).

[10] A PAUL, V RUBIO, J BINNER et al. Evaluation of the high temperature performance of HfB2 UHTC particulate filled Cf/C composites. International Journal of Applied Ceramic Technology, 14, 344(2017).

[11] W G FAHRENHOLTZ, E J WUCHINA, W E LEE et al. Ultra- high temperature ceramics:materials for extreme environment applications. Inc.(2014).

[12] W FAHRENHOLTZ, G HILMAS. Oxidation of ultra-high temperature transition metal diboride ceramics. International Materials Reviews, 57, 61(2012).

[13] E EAKINS, D D JAYASEELAN, W E LEE. Toward oxidation- resistant ZrB2-SiC ultra high temperature ceramics. Metallurgical and Materials Transactions A, 42: 878(2011).

[14] M M OPEKA, I G TALMY, E J WUCHINA et al. Mechanical, thermal, and oxidation properties of refractory hafnium and zirconium compounds. Journal of the European Ceramic Society, 19, 2405(1999).

[15] W G FAHRENHOLTZ, G E HILMAS, I G TALMY et al. Refractory diborides of zirconium and hafnium. Journal of the American Ceramic Society, 90, 1347(2007).

[16] J LIN, X ZHANG, W HAN. Comparison of ZrB2-ZrO2f ceramics prepared by hot pressing and pressureless sintering. International Journal of Refractory Metals & Hard Materials, 35: 102(2012).

[17] J LIN, X ZHANG, Z WANG et al. Microstructure and mechanical properties of hot-pressed ZrB2-SiC-ZrO2f ceramics with different sintering temperatures. Materials & Design, 34: 853(2012).

[18] P HU, K GUI, W HONG et al. High-performance ZrB2-SiC-Cf composite prepared by low-temperature hot pressing using nanosized ZrB2 powder. Journal of the European Ceramic Society, 37, 2317(2017).

[19] A BELLOSI, F MONTEVERDE, D SCITI. Fast densification of ultra-high-temperature ceramics by spark plasma sintering. International Journal of Applied Ceramic Technology, 3, 32(2006).

[20] P HU, Y CHENG, P WANG et al. Rolling compacted fabrication of carbon fiber reinforced ultra-high temperature ceramics with highly oriented architectures and exceptional mechanical feedback. Ceramics International, 44, 14907(2018).

[21] G J ZHANG, Z Y DENG, N KONDO et al. Reactive hot pressing of ZrB2-SiC composites. Journal of the American Ceramic Society, 83, 2330(2000).

[22] Q QU, J HAN, W HAN et al. In situ synthesis mechanism and characterization of ZrB2-ZrC-SiC ultra high-temperature ceramics. Materials Chemistry and Physics, 110, 216(2008).

[23] H Y WU, J ZOU, M ERIKSSON et al. Reactive sintering of 2.5D Cf/ZrC-SiC ceramic matrix composite. Journal of the European Ceramic Society, 41, 6189(2021).

[24] M A EINARSRUD, E HAGEN, G PETTERSEN et al. Pressureless sintering of titanium diboride with nickel, nickel boride and iron additives. Journal of the American Ceramic Society, 80, 3013(1997).

[25] J RODRíGUEZ-SÁNCHEZ, E SÁNCHEZ-GONZÁLEZ, F GUIBERTEAU et al. Contact-mechanical properties at intermediate temperatures of ZrB2 ultra-high-temperature ceramics pressureless sintered with Mo, Ta, or Zr disilicides. Journal of the European Ceramic Society, 35, 3179(2015).

[26] S C ZHANG, G HILMAS, W FAHRENHOLTZ. Pressureless densification of zirconium diboride with boron carbide additions. Journal of the American Ceramic Society, 89, 1544(2006).

[27] R HE, X ZHANG, P HU et al. Aqueous gelcasting of ZrB2-SiC ultra high temperature ceramics. Ceramics International, 38, 5411(2012).

[28] X CHEN, G CHENG, J ZHANG et al. Residual stress variation in SiCf/SiC composite during heat treatment and its effects on mechanical behavior. Journal of Advanced Ceramics, 9: 567(2020).

[29] C WANG, W PING, Q BAI et al. A general method to synthesize and sinter bulk ceramics in seconds. Science, 368: 521(2020).

[30] R WANG, Q DONG, C WANG et al. High-temperature ultrafast sintering

[32] B BAKER, V RUBIO, P RAMANUJAM et al. Development of a slurry injection technique for continuous fibre ultra-high temperature ceramic matrix composites. Journal of the European Ceramic Society, 39, 3927(2019).

[33] F SERVADEI, L ZOLI, P GALIZIA et al. Development of UHTCMCs

[34] L LI, Y WANG, L CHENG et al. Preparation and properties of 2D C/SiC-ZrB2-TaC composites. Ceramics International, 37, 891(2011).

[35] F UHLMANN, C WILHELMI, S SCHMIDT-WIMMER et al. Preparation and characterization of ZrB2 and TaC containing Cf/SiC composites

[36] C J LESLIE, E E BOAKYE, K A KELLER et al. Development of continuous SiC fiber reinforced HfB2-SiC composites for aerospace applications. Processing and Properties of Advanced Ceramics and Composites V: Ceramic Transactions, 240: 1(2013).

[37] S M TAMMANA, M DUAN, J ZOU et al. Ablation behaviour of Cf-ZrC-SiC with and without rare earth metal oxide dopants. Open Ceramics, 10: 100270(2022).

[38] H ZHOU, D NI, P HE et al. Ablation behavior of C/C-ZrC and C/SiC-ZrC composites fabricated by a joint process of slurry impregnation and chemical vapor infiltration. Ceramics International, 44, 4777(2018).

[39] Y ZHU, Z HUANG, S DONG et al. Manufacturing 2D carbon- fiber-reinforced SiC matrix composites by slurry infiltration and PIP process. Ceramics International, 34, 1201(2008).

[40] D ZHANG, P HU, S DONG et al. Microstructures and mechanical properties of Cf/ZrB2-SiC composite fabricated by nano slurry brushing combined with low-temperature hot pressing. Journal of Alloys and Compounds, 789: 755(2019).

[41] X ZHAO, Y WANG, L DUAN et al. Improved ablation resistance of C/SiC-ZrB2 composites

[42] C YAN, R LIU, B ZHA et al. Fabrication and properties of 3-dimensional 4-directional Cf/HfC-SiC composites by precursor impregnation and pyrolysis process. Journal of Alloys and Compounds, 739: 955(2018).

[43] J P ZHANG, Q G FU, L WANG. Preparation, ablation behavior and thermal retardant ability of C/C-HfB2-SiC composites. Materials & Design, 132: 552(2017).

[44] Y JIA, X YAO, J SUN et al. Effect of ZrC particle size on the ablation resistance of C/C-ZrC-SiC composites. Materials & Design, 129: 15(2017).

[45] Z WANG, S DONG, X ZHANG et al. Fabrication and properties of Cf/SiC-ZrC composites. Journal of the American Ceramic Society, 91, 3434(2008).

[46] R NASLAIN. Design, preparation and properties of non-oxide CMCs for application in engines and nuclear reactors: an overview. Composites Science and Technology, 64, 155(2004).

[47] D ZHAO, C ZHANG, H HU et al. Preparation and characterization of three-dimensional carbon fiber reinforced zirconium carbide composite by precursor infiltration and pyrolysis process. Ceramics International, 37, 2089(2011).

[48] Y YANG, S JAYARAMAN, D Y KIM et al. CVD growth kinetics of HfB2 thin films from the single-source precursor Hf(BH4)4. Chemistry of Materials, 18, 5088(2006).

[49] H WANG, X CHEN, B GAO et al. Synthesis and characterization of a novel precursor-derived ZrC/ZrB2 ultra-high-temperature ceramic composite. Applied Organometallic Chemistry, 27, 79(2013).

[50] H ZHOU, J YANG, G LE et al. Effect of ZrC amount and distribution on the thermomechanical properties of Cf/SiC-ZrC composites. International Journal of Applied Ceramic Technology, 16, 1321(2019).

[51] A NISAR, C ZHANG, B BOESL et al. A perspective on challenges and opportunities in developing high entropy-ultra high temperature ceramics. Ceramics International, 46, 25845(2020).

[52] Y TONG, S BAI, K CHEN. C/C-ZrC composite prepared by chemical vapor infiltration combined with alloyed reactive melt infiltration. Ceramics International, 38, 5723(2012).

[53] X CHEN, Q FENG, L GAO et al. Interphase degradation of three-dimensional Cf/SiC-ZrC-ZrB2 composites fabricated

[54] M KÜTEMEYER, L SCHOMER, T HELMREICH et al. Fabrication of ultra high temperature ceramic matrix composites using a reactive melt infiltration process. Journal of the European Ceramic Society, 36, 3647(2016).

[55] A VINCI, L ZOLI, P GALIZIA et al. Reactive melt infiltration of carbon fibre reinforced ZrB2/B composites with Zr2Cu. Composites Part A: Applied Science and Manufacturing, 137: 105973(2020).

[56] . Ceramic-matrix-composites[2023-12-31]. https://ultramet.com/ceramic-matrix-composites/

[57] L ZOU, N WALI, J M YANG et al. Microstructural characterization of a Cf/ZrC composite manufactured by reactive melt infiltration. International Journal of Applied Ceramic Technology, 8, 329(2011).

[59] B W CHEN, D W NI, J X WANG et al. Ablation behavior of Cf/ZrC-SiC-based composites fabricated by an improved reactive melt infiltration. Journal of the European Ceramic Society, 39, 4617(2019).

[60] J BINNER, M PORTER, B BAKER et al. Selection, processing, properties and applications of ultra-high temperature ceramic matrix composites, UHTCMCs—a review. International Materials Reviews, 65, 389(2020).

[61] V RUBIO, P RAMANUJAM, J BINNER. Ultra-high temperature ceramic composite. Advances in Applied Ceramics, 117, s56(2018).

[62] J REN, E FENG, Y ZHANG et al. Microstructure and anti-ablation performance of HfC-TaC and HfC-ZrC coatings synthesized by CVD on C/C composites. Ceramics International, 46, 10147(2020).

[63] M TONG, Q FU, L ZHOU et al. Ablation behavior of a novel HfC-SiC gradient coating fabricated by a facile one-step chemical vapor co-deposition. Journal of the European Ceramic Society, 38, 4346(2018).

[64] H HU, Y ZHANG, X HE et al. Rapid densification of C/SiC composites by joint processes of CLVD and PIP.. Materials Letters, 65, 3137(2011).

[65] G L VIGNOLES, R DUCLOUS, S GAILLARD. Analytical stability study of the densification front in carbon-or ceramic- matrix composites processing by TG-CVI. Chemical Engineering Science, 62, 6081(2007).

[66] Z H TANG, D N QU, J XIONG et al. Effects of infiltration conditions on the densification behavior of carbon/carbon composites prepared by a directional-flow thermal gradient CVI process. Carbon, 41, 2703(2003).

[67] T TAGUCHI, T NOZAWA, N IGAWA et al. Fabrication of advanced SiC fiber/F-CVI SiC matrix composites with SiC/C multi- layer interphase. Journal of Nuclear Materials, 329: 572(2004).

[68] V VENKATACHALAM, S BLEM, A GÜLHAN et al. Thermal qualification of the UHTCMCs produced using RF-CVI technique with VMK facility at DLR.. Journal of Composites Science, 6, 24(2022).

[69] R R NASLAIN, R PAILLER, X BOURRAT et al. Synthesis of highly tailored ceramic matrix composites by pressure-pulsed CVI.. Solid State Ionics, 141: 541(2001).

[70] Y CHENG, P HU, W ZHANG et al. One-step introduction of ZrC-SiC inside carbon fabric to fabricate high homogeneous and damage-tolerant composite inspired by vibration. Journal of the European Ceramic Society, 39, 2251(2019).

[71] P HU, Y CHENG, D ZHANG et al. From ferroconcrete to Cf/UHTC-SiC: a totally novel densification method and mechanism at 1300 °C without pressure. Composites Part B: Engineering, 174: 107023(2019).

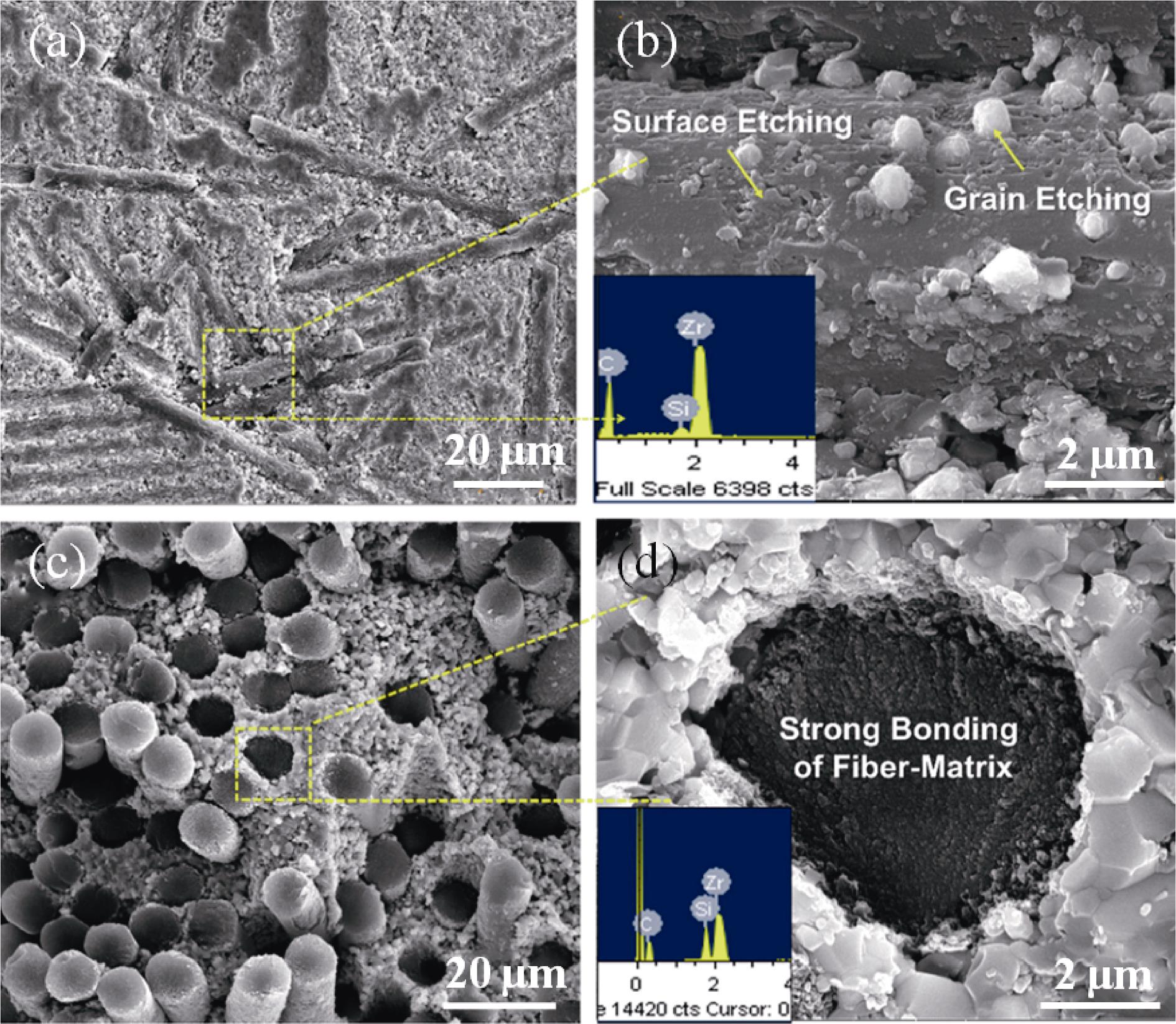

[72] P HU, D ZHANG, S DONG et al. A novel vibration-assisted slurry impregnation to fabricate Cf/ZrB2-SiC composite with enhanced mechanical properties. Journal of the European Ceramic Society, 39, 798(2019).

[73] D ZHANG, P HU, S DONG et al. Oxidation behavior and ablation mechanism of Cf/ZrB2-SiC composite fabricated by vibration- assisted slurry impregnation combined with low-temperature hot pressing. Corrosion Science, 161: 108181(2019).

[74] D ZHANG, J FENG, P HU et al. Enhanced mechanical properties and thermal shock resistance of Cf/ZrB2-SiC composite

[75] J SUN, S YU, J WADE-ZHU et al. 3D printing of layered ceramic/carbon fiber composite with improved toughness. Additive Manufacturing, 50: 102543(2022).

[76] H FU, W ZHU, Z XU et al. Effect of silicon addition on the microstructure, mechanical and thermal properties of Cf/SiC composite prepared

[77] X LV, F YE, L CHENG et al. 3D printing “wire-on-sphere” hierarchical SiC nanowires/SiC whiskers foam for efficient high-temperature electromagnetic wave absorption. Journal of Materials Science & Technology, 109: 94(2022).

[78] Z ZHAO, G ZHOU, Z YANG et al. Direct ink writing of continuous SiO2 fiber reinforced wave-transparent ceramics. Journal of Advanced Ceramics, 9: 403(2020).

[79] J W KEMP, A A DIAZ, E C MALEK et al. Direct ink writing of ZrB2-SiC chopped fiber ceramic composites. Additive Manufacturing, 44: 102049(2021).

[81] J HAN, C LIU, R L BRADFORD-VIALVA et al. Additive manufacturing of advanced ceramics using preceramic polymers. Materials, 16, 4636(2023).

[82] Y LIU, Y CHENG, D MA et al. Continuous carbon fiber reinforced ZrB2-SiC composites fabricated by direct ink writing combined with low-temperature hot-pressing. Journal of the European Ceramic Society, 42, 3699(2022).

[83] D ALFANO, R GARDI, L SCATTEIA et al. UHTC-based hot structures: characterization, design, and on-ground/in-flight testing. Ultra-High Temperature Ceramics: Materials for Extreme Environment Applications.

[85] M S ASL, M G KAKROUDI, S NOORI. Hardness and toughness of hot pressed ZrB2-SiC composites consolidated under relatively low pressure. Journal of Alloys and Compounds, 619: 481(2015).

[86] S KIM, J M CHAE, S M LEE et al. Change in microstructures and physical properties of ZrB2-SiC ceramics hot-pressed with a variety of SiC sources. Ceramics International, 40, 3477(2014).

[87] L SILVESTRONI, D SCITI, C MELANDRI et al. Toughened ZrB2- based ceramics through SiC whisker or SiC chopped fiber additions. Journal of the European Ceramic Society, 30, 2155(2010).

[88] D SCITI, L PIENTI, FABBRICHE D DALLE et al. Combined effect of SiC chopped fibers and SiC whiskers on the toughening of ZrB2. Ceramics International, 40, 4819(2014).

[89] B R GOLLA, A MUKHOPADHYAY, B BASU et al. Review on ultra-high temperature boride ceramics. Progress in Materials Science, 111: 100651(2020).

[90] N P VAFA, M G KAKROUDI, M S ASL. Advantages and disadvantages of graphite addition on the characteristics of hot-pressed ZrB2-SiC composites. Ceramics International, 46, 8561(2020).

[91] Y CHENG, Y LYU, S ZHOU et al. Non-axially aligned ZrB2-SiC/ZrB2-SiC-graphene short fibrous monolithic ceramics with isotropic in-plane properties. Ceramics International, 45, 4113(2019).

[92] I FARAHBAKHSH, Z AHMADI, M S ASL. Densification, microstructure and mechanical properties of hot pressed ZrB2-SiC ceramic doped with nano-sized carbon black. Ceramics International, 43, 8411(2017).

[93] Y CHENG, P HU, S ZHOU et al. Using macroporous graphene networks to toughen ZrC-SiC ceramic. Journal of the European Ceramic Society, 38, 3752(2018).

[94] W B TIAN, Y M KAN, G J ZHANG et al. Effect of carbon nanotubes on the properties of ZrB2-SiC ceramics. Materials Science and Engineering: A, 487, 568(2008).

[95] H JIN, S MENG, W XIE et al. HfB2-CNTs composites with enhanced mechanical properties prepared by spark plasma sintering. Ceramics International, 43, 2170(2017).

[96] P ZHOU, P HU, X ZHANG et al. R-curve behavior of laminated ZrB2-SiC ceramic with strong interfaces. International Journal of Refractory Metals and Hard Materials, 52: 12(2015).

[97] K GUI, F LIU, G WANG et al. Microstructural evolution and performance of carbon fiber-toughened ZrB2 ceramics with SiC or ZrSi2 additive. Journal of Advanced Ceramics, 7: 343(2018).

[99] F YANG, X ZHANG, J HAN et al. Characterization of hot-pressed short carbon fiber reinforced ZrB2-SiC ultra-high temperature ceramic composites. Journal of Alloys and Compounds, 472: 395(2009).

[100] M MOR, A VINCI, S FAILLA et al. A novel approach for manufacturing of layered, ultra-refractory composites using pliable, short fibre-reinforced ceramic sheets. Journal of Advanced Ceramics, 12, 155(2023).

[101] Y CHENG, C LIU, P HU et al. Using PyC coated short chopped carbon fiber to tackle the dilemma between toughness and strength of ZrC-SiC. Ceramics International, 45, 503(2019).

[102] D NI, Y CHENG, J ZHANG et al. Advances in ultra-high temperature ceramics composites and coatings. Journal of Advanced Ceramics, 11: 1(2022).

[103] C LI, G LI, H OUYANG et al. Microstructure and properties of C/C-ZrC composites prepared by hydrothermal deposition combined with carbothermal reduction. Journal of Alloys and Compounds, 741: 323(2018).

[104] P GALIZIA, S FAILLA, L ZOLI et al. Tough salami-inspired Cf/ZrB2 UHTCMCs produced by electrophoretic deposition. Journal of the European Ceramic Society, 38, 403(2018).

[105] A Y MATVEEVA, S V LOMOV, L GORBATIKH. Debonding at the fiber/matrix interface in carbon nanotube reinforced composites: modelling investigation. Computational Materials Science, 159: 412(2019).

[106] J LI, Y ZHANG, Y FU et al. A simple and efficient route to synthesize hafnium carbide nanowires by catalytic pyrolysis of a polymer precursor. Ceramics International, 44, 13335(2018).

[107] D WANG, S DONG, H ZHOU et al. Effect of pyrolytic carbon interface on the properties of 3D C/ZrC-SiC composites fabricated by reactive melt infiltration. Ceramics International, 42, 10272(2016).

[108] G BOITIER, S DARZENS, J L CHERMANT et al. Microstructural investigation of interfaces in CMCs. Composites Part A: Applied Science and Manufacturing, 33, 1467(2002).

[109] R J KERANS, R S HAY, T A PARTHASARATHY et al. Interface design for oxidation-resistant ceramic composites. Journal of the American Ceramic Society, 85, 2599(2002).

[110] D W NI, J X WANG, S M DONG et al. Fabrication and properties of Cf/ZrC-SiC-based composites by an improved reactive melt infiltration. Journal of the American Ceramic Society, 101, 3253(2018).

[111] C FANG, P HU, S DONG et al. An efficient hydrothermal transformation approach for construction of controllable carbon coating on carbon fiber from renewable carbohydrate. Applied Surface Science, 491: 478(2019).

[112] Y BOULIGAND. Twisted fibrous arrangements in biological materials and cholesteric mesophases. Tissue and Cell, 4, 189(1972).

[113] Y AN, M SONG, K WAN et al. Anisotropic friction properties of biomimetic Cf/ZrB2-SiC ceramic composites with bouligand structures. Tribology International, 186: 108638(2023).

[114] Y AN, K WAN, Y YANG et al. Fabrication method and mechanical properties of biomimetic Cf/ZrB2-SiC ceramic composites with bouligand structures. Journal of the European Ceramic Society, 43, 283(2023).

[115] J W ZIMMERMANN, G E HILMAS, W G FAHRENHOLTZ. Thermal shock resistance and fracture behavior of ZrB2-based fibrous monolith ceramics. Journal of the American Ceramic Society, 92, 161(2009).

[116] P ZHOU, P HU, X ZHANG et al. Laminated ZrB2-SiC ceramic with improved strength and toughness. Scripta Materialia, 64, 276(2011).

[117] Y HAN, X LIU, Q ZHANG et al. Ultra-dense dislocations stabilized in high entropy oxide ceramics. Nature Communications, 13: 2871(2022).

[118] A PAUL, S VENUGOPAL, J BINNER et al. UHTC-carbon fibre composites: preparation, oxyacetylene torch testing and characterisation. Journal of the European Ceramic Society, 33, 423(2013).

[119] J P ZHANG, J L QU, Q G FU. Ablation behavior of nose-shaped HfB2-SiC modified carbon/carbon composites exposed to oxyacetylene torch. Corrosion Science, 151: 87(2019).

[120] F MONTEVERDE, R SAVINO, M D S FUMO et al. Plasma wind tunnel testing of ultra-high temperature ZrB-SiC composites under hypersonic re-entry conditions. Journal of the European Ceramic Society, 30, 2313(2010).

[121] Q LI, S DONG, Z WANG et al. Fabrication and properties of 3D Cf/SiC-ZrC composites using ZrC precursor and polycarbosilane. Journal of the American Ceramic Society, 95, 1216(2012).

[122] S MUNGIGUERRA, MARTINO G DI, A CECERE et al. Arc-jet wind tunnel characterization of ultra-high-temperature ceramic matrix composites. Corrosion Science, 149: 18(2019).

[123] R SAVINO, L CRISCUOLO, MARTINO G D DI et al. Aero-thermo-chemical characterization of ultra-high-temperature ceramics for aerospace applications. Journal of the European Ceramic Society, 38, 2937(2018).

[124] S TANG, J DENG, S WANG et al. Fabrication and characterization of an ultra-high-temperature carbon fiber-reinforced ZrB2-SiC matrix composite. Journal of the American Ceramic Society, 90, 3320(2007).

[125] S TANG, J DENG, S WANG et al. Ablation behaviors of ultra-high temperature ceramic composites. Materials Science and Engineering: A, 465, 1(2007).

[126] Y ZENG, D WANG, X XIONG et al. Ultra-high-temperature ablation behavior of SiC-ZrC-TiC modified carbon/carbon composites fabricated

[128] Y CHENG, P HU, S DONG et al. Dual bionics of structure and preparation

[129] J GILD, Y ZHANG, T HARRINGTON et al. High-entropy metal diborides: a new class of high-entropy materials and a new type of ultrahigh temperature ceramics. Scientific Reports, 6: 37946(2016).

[130] F WANG, L XU, J ZOU et al. Pressureless densification and properties of high-entropy boride ceramics with B4C additions. Journal of Materials Science & Technology, 190: 1(2024).

[131] L BACKMAN, J GILD, J LUO et al. Part I: theoretical predictions of preferential oxidation in refractory high entropy materials. Acta Materialia, 197: 20(2020).

[132] Y ZENG, D WANG, X XIONG et al. Ablation-resistant carbide Zr0.8Ti0.2C0.74B0.26 for oxidizing environments up to 3000 ℃. Nature Communications, 8: 15836(2017).

[133] F CAI, D NI, B CHEN et al. Fabrication and properties of Cf/(Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2) C-SiC high-entropy ceramic matrix composites

[134] C ZHANG, B BOESL, A AGARWAL. Oxidation resistance of tantalum carbide-hafnium carbide solid solutions under the extreme conditions of a plasma jet.. Ceramics International, 43, 14798(2017).

[135] Y CHENG, Y LYU, Y XIE et al. Starting from essence to reveal the ablation behavior and mechanism of 3D PyC Cf/ZrC-SiC composite. Corrosion Science, 201: 110261(2022).

[136] D BOSE, M OLSON, B LAUB et al. Initial assessment of Mars Science Laboratory heatshield instrumentation and flight data. 51st AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Texas(2013).

[137] K A TRUMBLE, I COZMUTA, S SEPKA et al. Postflight aerothermal analysis of the stardust sample return capsule. Journal of Spacecraft and Rockets, 47, 765(2010).

[138] P GUO, J LI, S PANG et al. Ultralight carbon fiber felt reinforced monolithic carbon aerogel composites with excellent thermal insulation performance. Carbon, 183: 525(2021).

[139] N LEVENTIS, A SADEKAR, N CHANDRASEKARAN et al. Click synthesis of monolithic silicon carbide aerogels from polyacrylonitrile-coated 3D silica networks. Chemistry of Materials, 22, 2790(2010).

[140] X WANG, J LIU, F HOU et al. Manufacture of porous SiC/C ceramics with excellent damage tolerance by impregnation of LPCS into carbonized pinewood. Journal of the European Ceramic Society, 35, 1751(2015).

[141] F LI, J X LIU, X HUANG et al. Carbothermal conversion of self-supporting organic/inorganic interpenetrating networks to porous metal boride monoliths. Journal of the American Ceramic Society, 102, 5746(2019).

[143] A BENAD, F JÜRRIES, B VETTER et al. Mechanical properties of metal oxide aerogels. Chemistry of Materials, 30, 145(2018).

[144] M ZHANG, Y WANG, Y ZHANG et al. Conductive and elastic TiO2 nanofibrous aerogels: a new concept toward self-supported electrocatalysts with superior activity and durability. Angewandte Chemie International Edition, 59, 23252(2020).

[145] T KIDCHOB, L MALFATTI, F SERRA et al. Hafnia sol-gel films synthesized from HfCl4: changes of structure and properties with the firing temperature. Journal of Sol-Gel Science and Technology, 42: 89(2007).

[146] K ZHAO, F YE, L CHENG et al. Formation of ultra-high temperature ceramic hollow microspheres as promising lightweight thermal insulation materials

[147] K WEI, X CHENG, F MO et al. Design and analysis of integrated thermal protection system based on lightweight C/SiC pyramidal lattice core sandwich panel. Materials & Design, 111: 435(2016).

[148] K WEI, R HE, X CHENG et al. A lightweight, high compression strength ultra high temperature ceramic corrugated panel with potential for thermal protection system applications. Materials & Design, 66: 552(2015).

[149] N SHIMODA. Functionally graded materials. Functionally Graded Materials Forum(1990).

[150] A K NAIK, M NAZEER, D PRASAD et al. Development of functionally graded ZrB2-B4C composites for lightweight ultrahigh-temperature aerospace applications. Ceramics International, 48, 33332(2022).